Sludge drying incineration all-in-one machine

A sludge drying and integrated machine technology, which is applied in dewatering/drying/concentrating sludge treatment, incinerators, combustion methods, etc., can solve the problems of easy generation of a large amount of dioxins, large equipment footprint, and inconvenient operation. , to achieve the effect of convenient management, reducing floor space and improving drying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

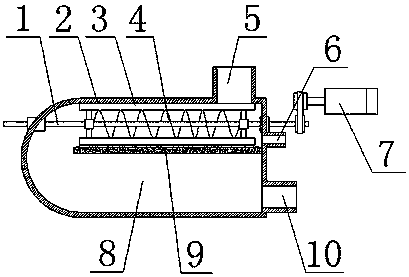

[0018] An integrated machine for sludge drying and incineration, comprising a box body 2, a screw pushing device 4 and a motor 7, a flue gas outlet 5 is opened above the box body 2, a sludge inlet 6 is opened on the right side of the box body 2, and the box body 2 The upper part is a sludge drying chamber, and the lower part is a sludge incineration chamber 8. The sludge drying chamber is separated by a heat conduction plate 9 between the sludge incineration chambers 8. A sludge outlet 10 is provided on the right side of the sludge incineration chamber 8. The spiral The pushing device 4 is set in the sludge drying chamber in the upper part of the box body 2, the screw pushing device 4 is fixed by the rotating shaft 1, and the rotating shaft 1 is connected to the motor 7 through a belt transmission, and the sludge scraper 3 is arranged on the outside of the screw pushing device 4 . An application method of a sludge drying and incinerating integrated machine is as follows: befor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com