Production method of shoes

A production method and technology for shoes, applied in footwear, other household appliances, household appliances, etc., can solve the problems of long time, cumbersome and complicated process, and reduce the production efficiency of shoes, so as to shorten the time, improve the production efficiency, and reduce the waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0040] A method for producing shoes, specifically as follows:

[0041] Step 1: According to the design needs, cut the corresponding size and shape of the fabric;

[0042] Step 2: Use a sewing machine to sew the end and end of the fabric to form the shape of the upper;

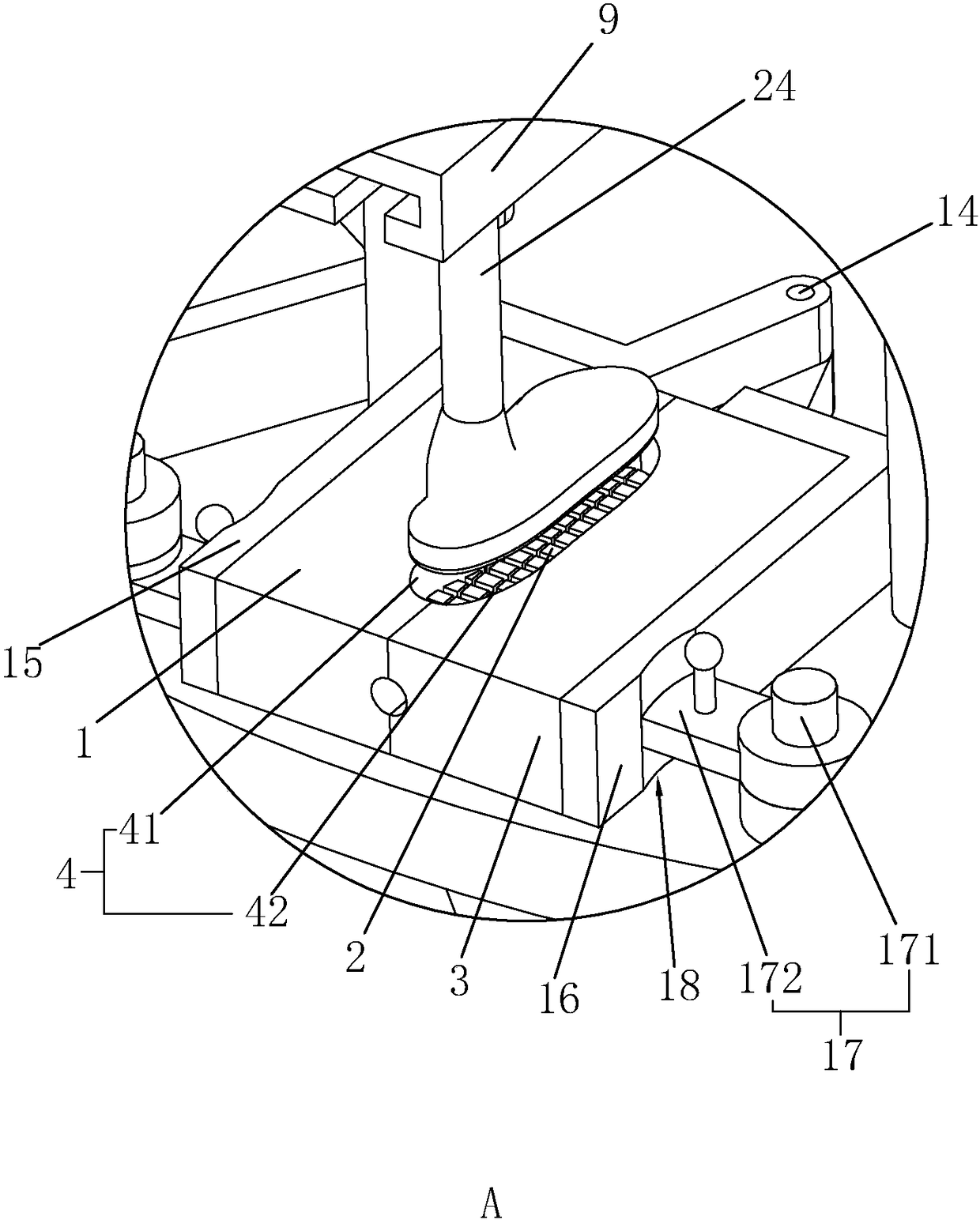

[0043] Step 3: Tighten the upper of the shoe to the top of the last 24 through the sewing thread on the upper;

[0044] Step 4: Hitting the heel height with a mallet to install the heel on the bottom of the last 24;

[0045] Step 5: pressing the shoe last 24 onto the forming mold, and forming a molding cavity for molding the sole between the shoe last 24 and the forming mold;

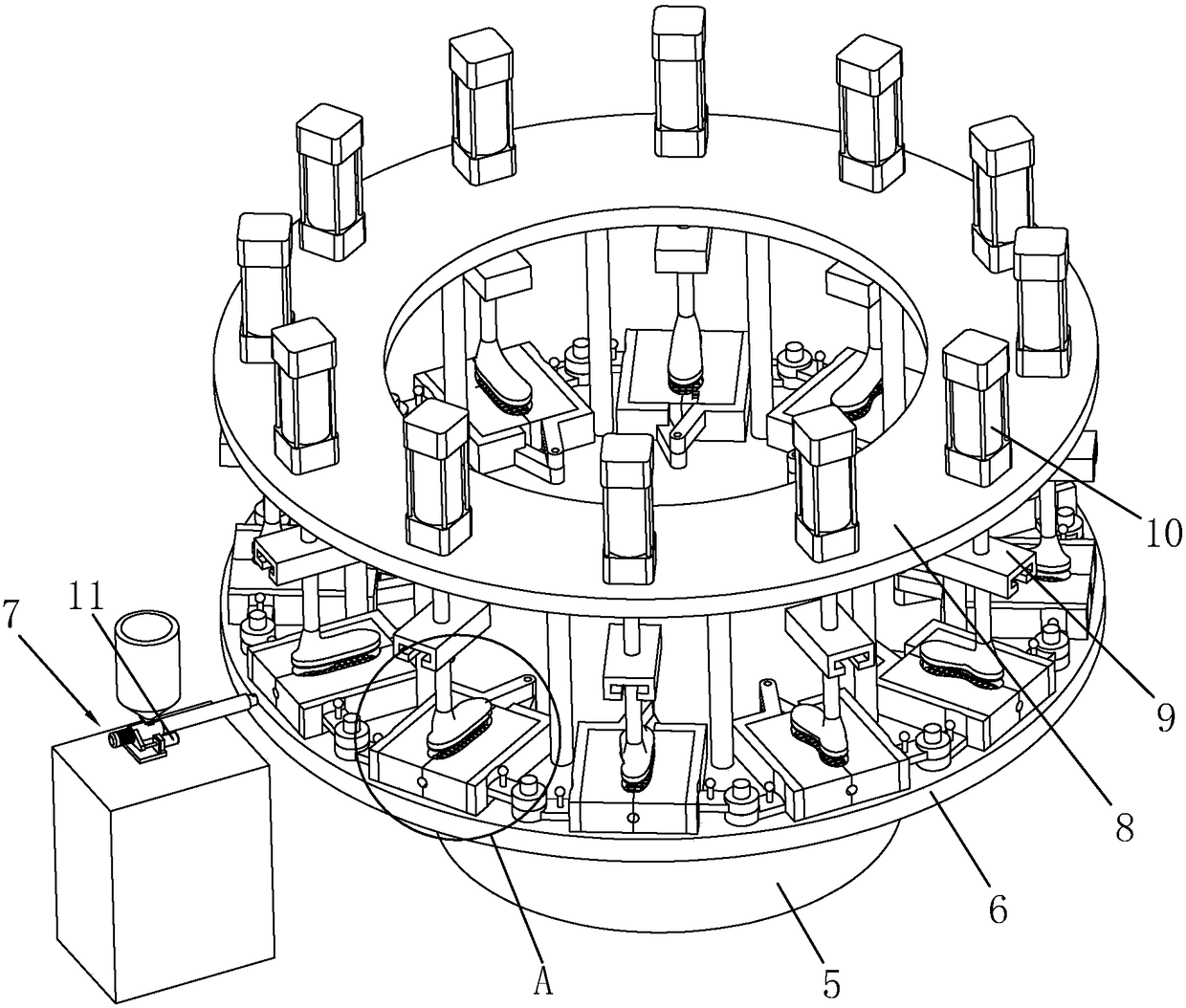

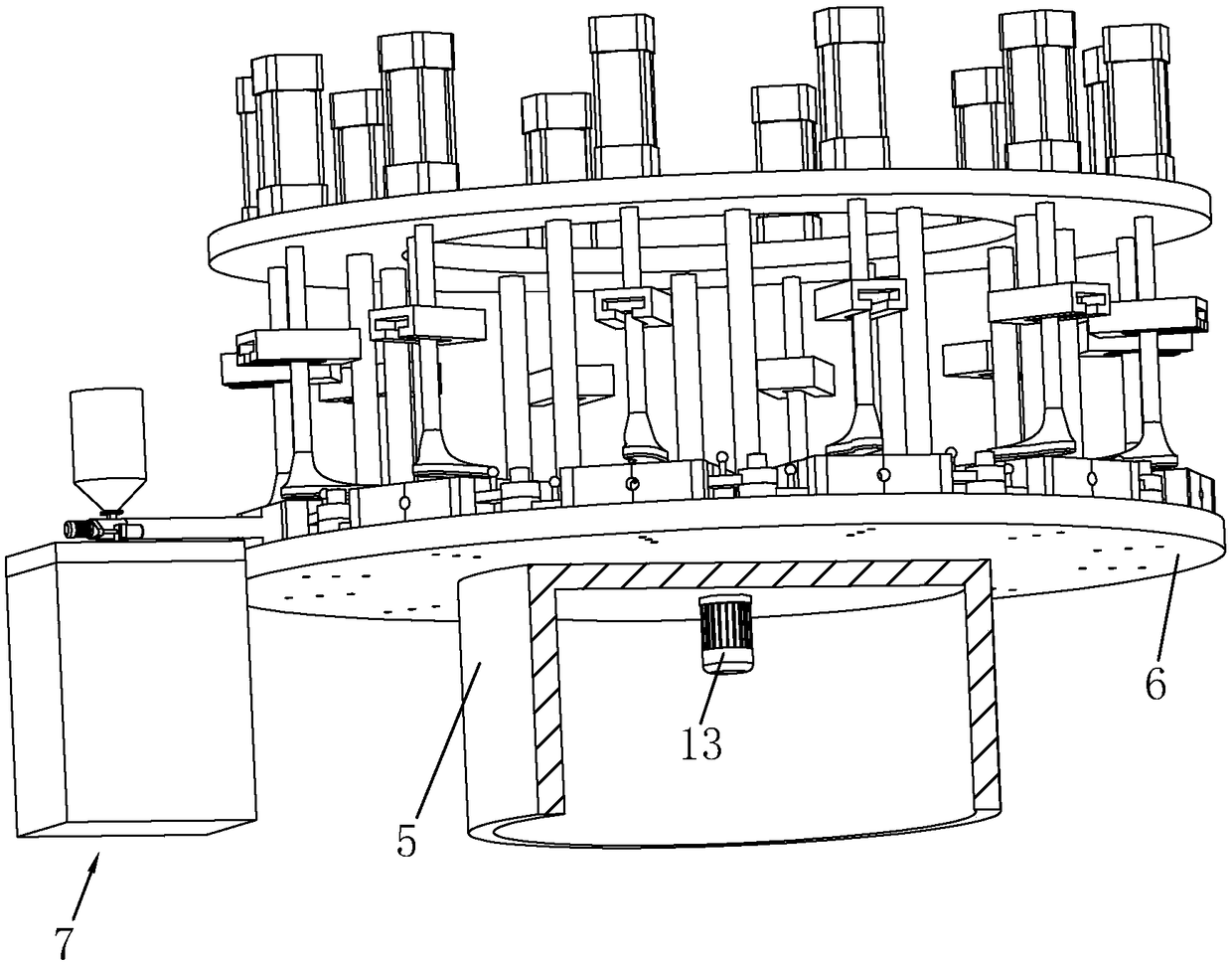

[0046] Step 6: Install the shoe last 24 and the forming mold on the injection molding device as a whole;

[0047] Step 7: Start the injection molding device, and inject injection molding liquid into the molding cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com