Movable-clearing center equipment

A central equipment and mobile rack technology, applied in the direction of removing smoke and dust, cleaning methods and utensils, separating solids from solids with airflow, etc., it can solve the problems of incomplete dust treatment, time-consuming energy consumption, inflexible movement, etc. problems, to achieve the effect of facilitating mobile operations, improving perforation performance, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

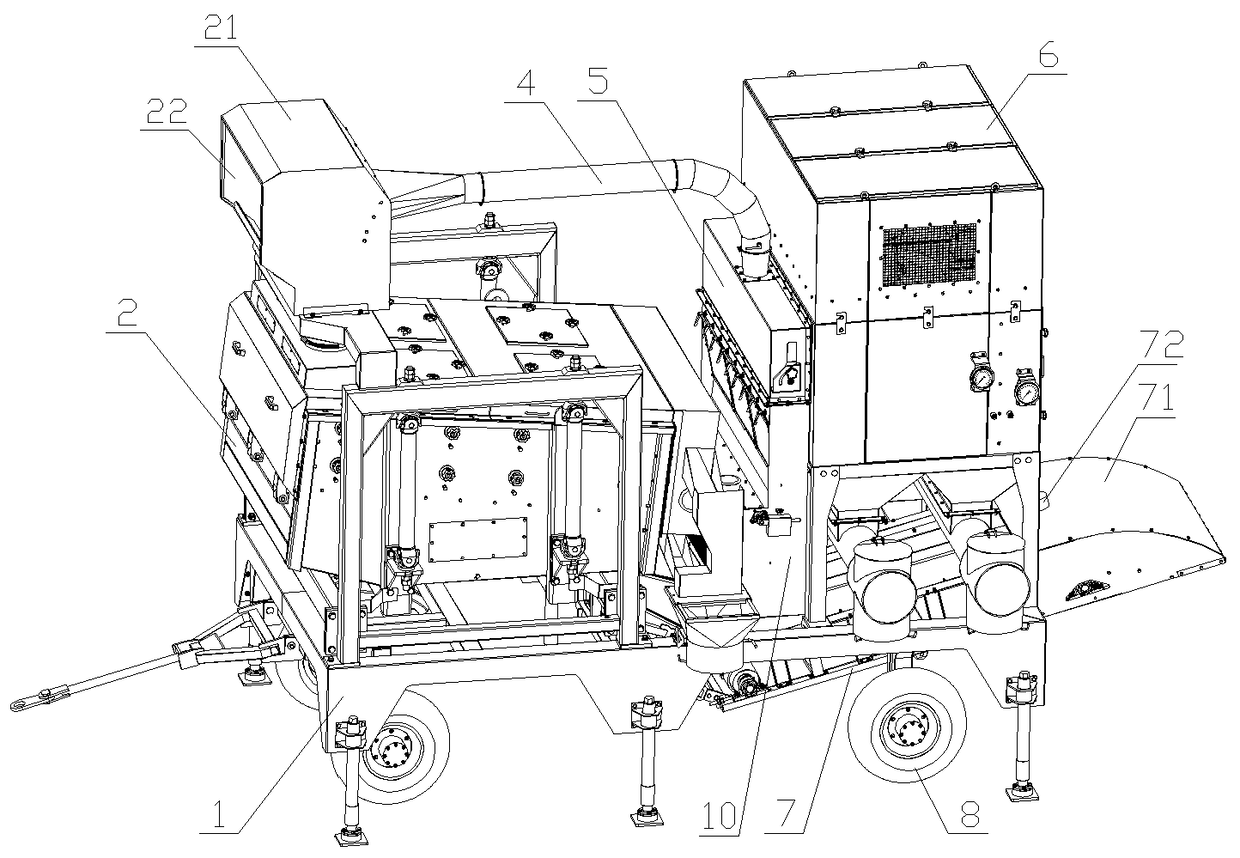

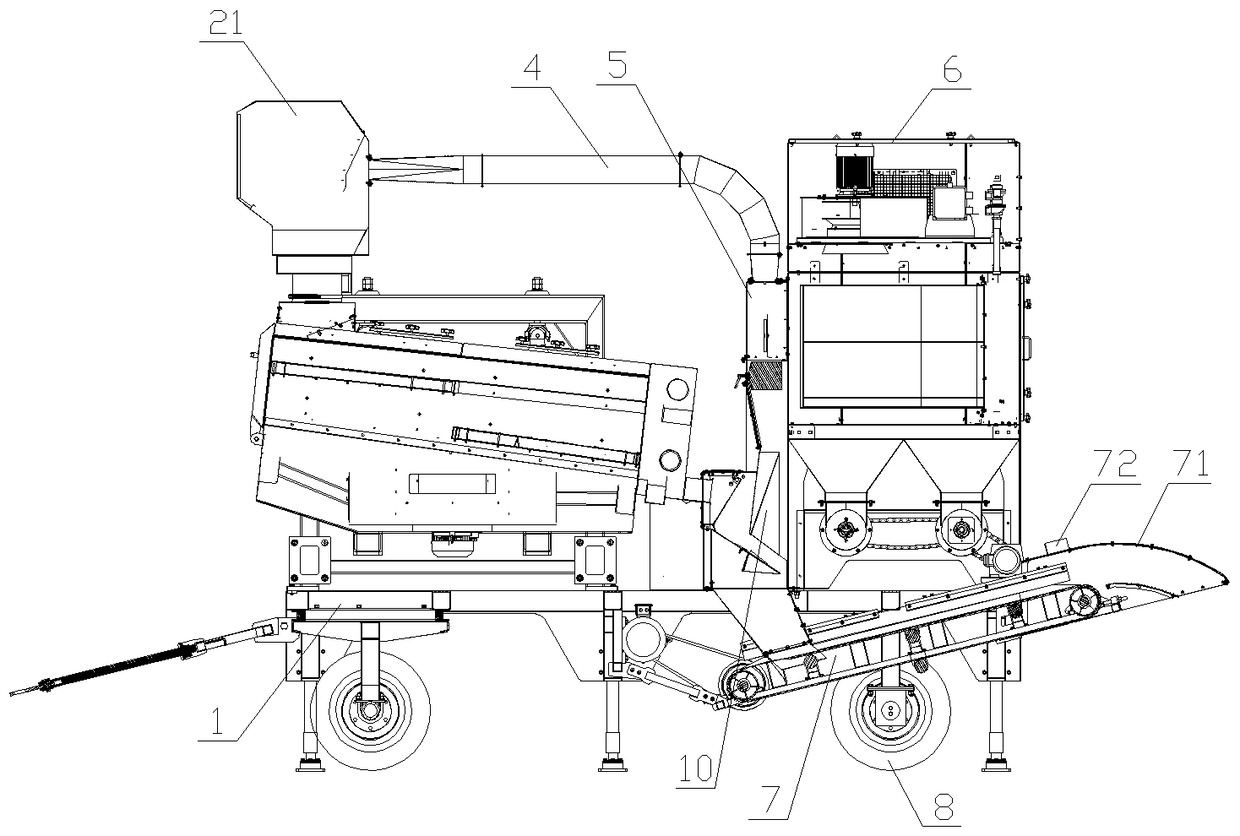

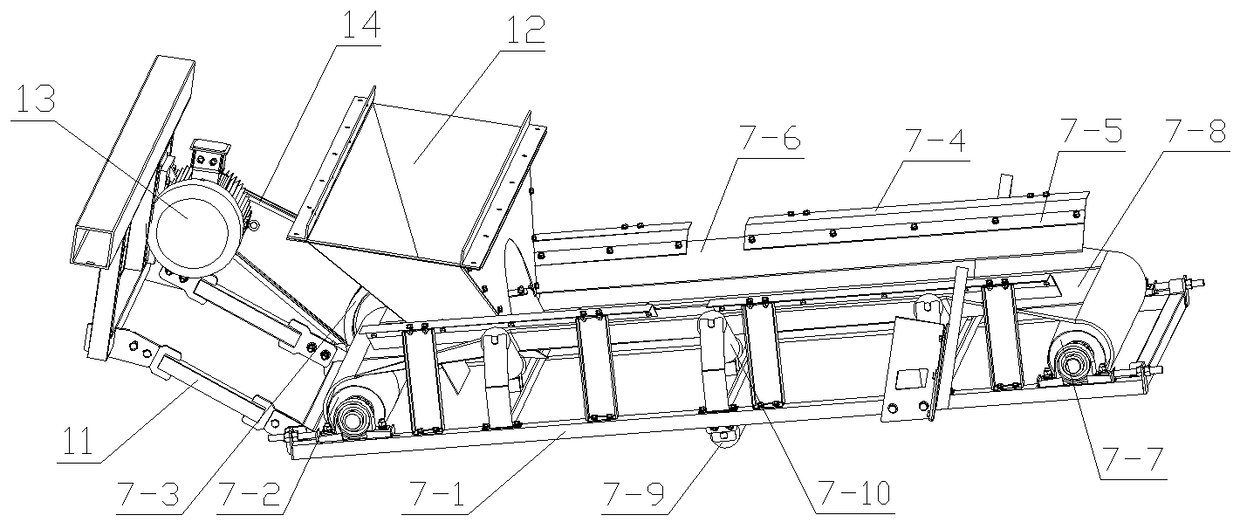

[0032] as attached Figure 1-5As shown, a mobile cleaning center equipment includes a mobile frame 1, a cleaning screen 2 installed on the mobile frame 1, a grain receiving hopper 21 fixed above the feed port of the cleaning screen 2, and a grain receiving bucket 21 fixed on the mobile frame 1. The dust collector 6 on the top, the suction box 5 arranged on the mobile frame 1 and connected to the dust collector 6, the inclined conveyor 7 and the dust suction channel arranged under the mobile frame; the inclined conveyor 7 is provided with dust collecting Cover 71. Road wheels 8 are arranged below the mobile frame 1 . The dust suction channel includes the first dust suction air duct 4 connected between the grain receiving hopper 21 and the suction box 5, the first dust suction duct 4 arranged between the discharge port of the cleaning screen 2 and the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com