Gardening tent with large coverage area

A covering area and tent technology, applied in horticulture, application, coating, etc., can solve the problems of complex internal skeleton structure, insufficient fit of tents, large number of steel frames, etc., and achieve the effect of improving heat preservation effect and reflective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

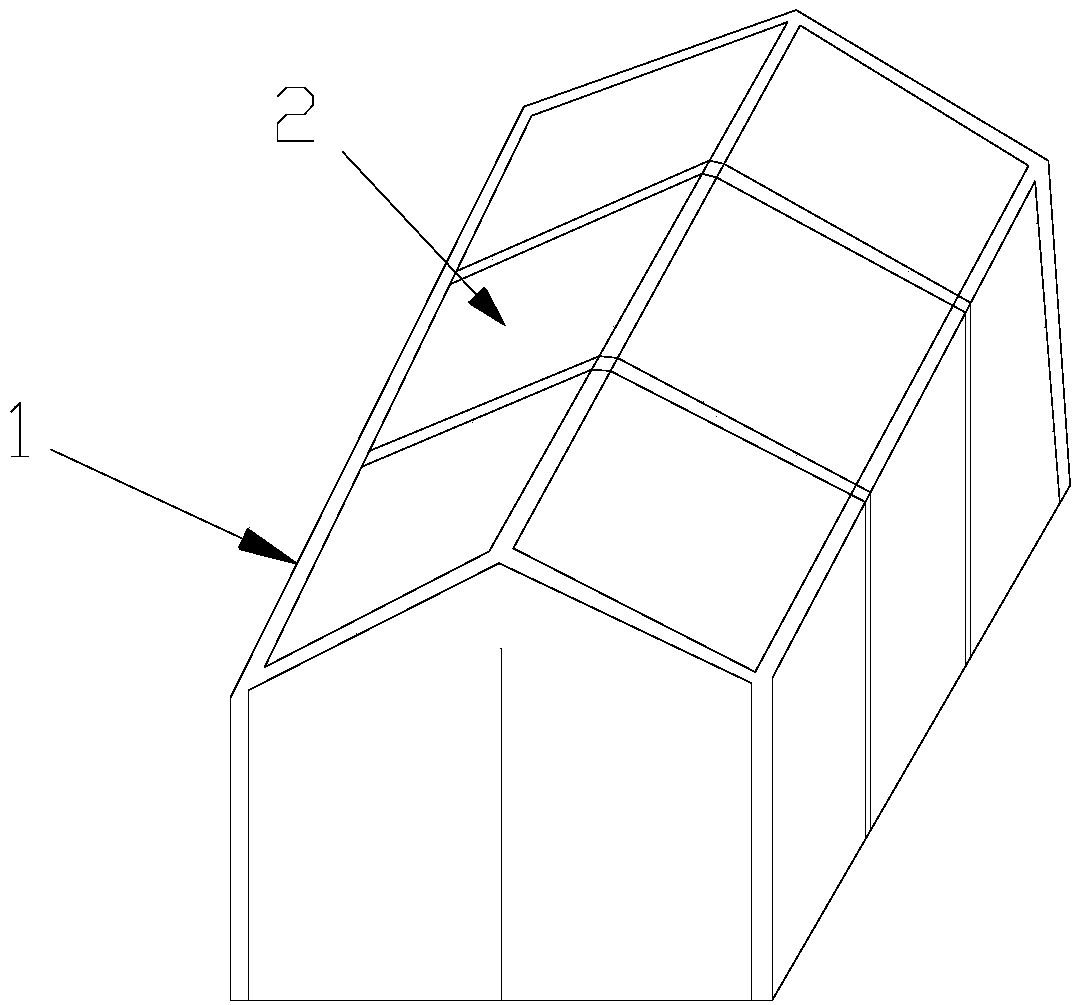

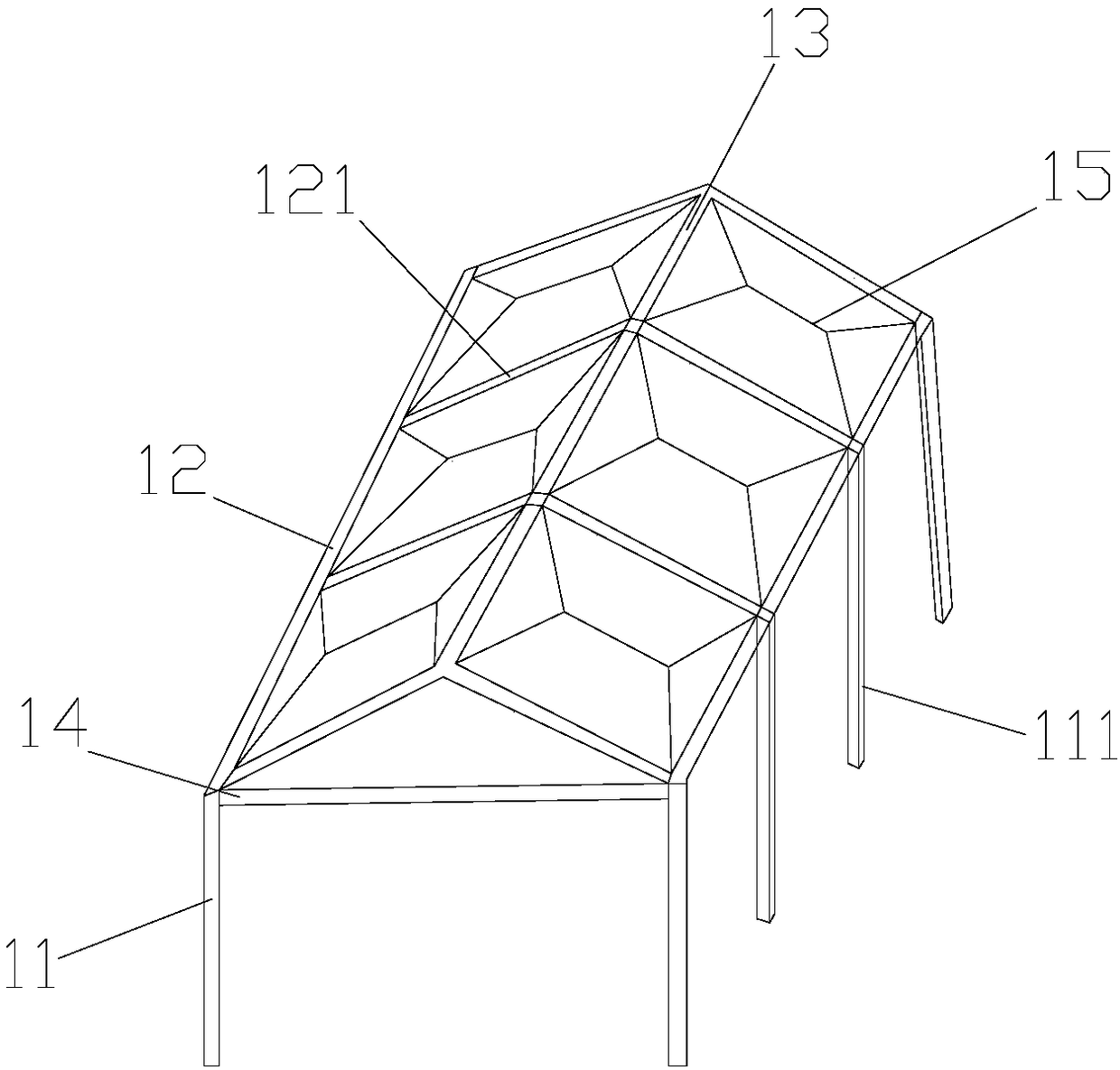

[0030] A gardening tent with a large coverage area, such as figure 1 As shown, it includes a skeleton 1, and a tent fabric 2 laid on the top of the skeleton and fixed with the skeleton 1; as figure 2 As shown, the frame 1 includes a main support column 11, a first cross bar 12 arranged above the two sides of the support column 11 and fixed with the main support column 11 by welding, and a main keel arranged on the top of the frame 1 13, and the second cross bar 14 that is arranged on the front and back of the skeleton 1 and is fixed by welding with the main support column 11; a side column 111 is arranged between the two main support columns 11, and the upper end of the side column 11 is connected to the The first cross bar 12 is welded and fixed.

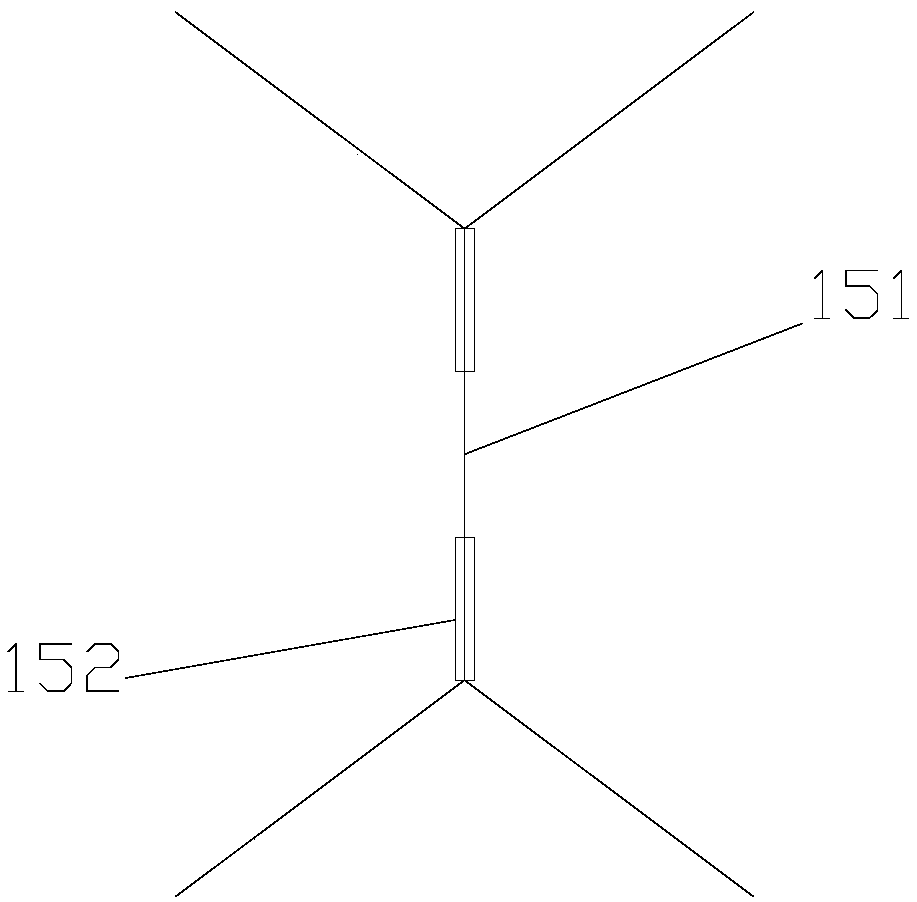

[0031] Such as image 3 As shown, a connecting rod 121 is arranged between the first cross bar 12 and the Zhu main keel 13, and a reinforcing mesh 15 for supporting the tent fabric 2 is also arranged between the two adjacent con...

Embodiment 2

[0043] A gardening tent with a large coverage area, such as figure 1 As shown, it includes a skeleton 1, and a tent fabric 2 laid on the top of the skeleton and fixed with the skeleton 1; as figure 2 As shown, the frame 1 includes a main support column 11, a first cross bar 12 arranged above the two sides of the support column 11 and fixed with the main support column 11 by welding, and a main keel arranged on the top of the frame 1 13, and the second cross bar 14 that is arranged on the front and back of the skeleton 1 and is fixed by welding with the main support column 11; a side column 111 is arranged between the two main support columns 11, and the upper end of the side column 11 is connected to the The first cross bar 12 is welded and fixed.

[0044] Such as image 3 As shown, a connecting rod 121 is arranged between the first cross bar 12 and the Zhu main keel 13, and a reinforcing mesh 15 for supporting the tent fabric 2 is also arranged between the two adjacent con...

Embodiment 3

[0056] A gardening tent with a large coverage area, such as figure 1 As shown, it includes a skeleton 1, and a tent fabric 2 laid on the top of the skeleton and fixed with the skeleton 1; as figure 2 As shown, the frame 1 includes a main support column 11, a first cross bar 12 arranged above the two sides of the support column 11 and fixed with the main support column 11 by welding, and a main keel arranged on the top of the frame 1 13, and the second cross bar 14 that is arranged on the front and back of the skeleton 1 and is fixed by welding with the main support column 11; a side column 111 is arranged between the two main support columns 11, and the upper end of the side column 11 is connected to the The first cross bar 12 is welded and fixed.

[0057] Such as image 3 As shown, a connecting rod 121 is arranged between the first cross bar 12 and the Zhu main keel 13, and a reinforcing mesh 15 for supporting the tent fabric 2 is also arranged between the two adjacent con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com