Method for testing performance of coatings of ballast tank and piping system thereof in electrolytic ballast water environment

A test method and ballast tank technology, applied in the field of experimentation, can solve problems such as not existing, affecting coating protection life, blank, etc., to achieve the effect of improving detection efficiency and shortening the research and development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

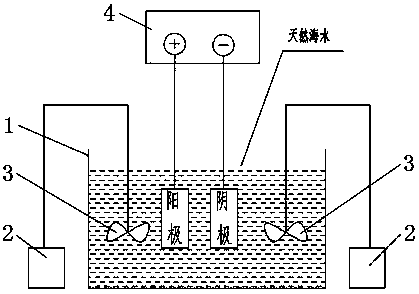

[0041] The coating samples were soaked in natural seawater and electrolyzed seawater with different residual chlorine concentrations and simulated ballast tank tests to compare the performance changes of the coating samples, so as to study the influence of electrolyzed seawater on ballast tank coatings.

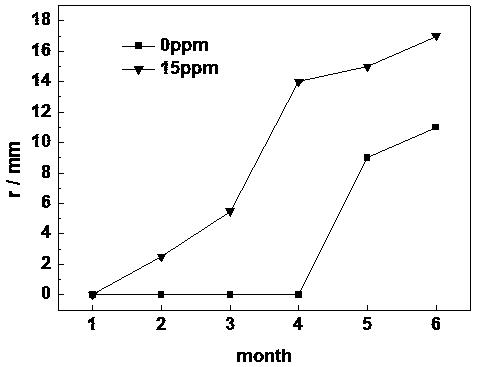

[0042] (1) Carry out the experiment of step (3)a according to the above requirements, and soak the test sample in natural seawater (with a residual chlorine concentration of 0ppm) and electrolytic seawater with a residual chlorine concentration of 15ppm, respectively, and the test temperature is room temperature. At the 1st, 2nd, 3rd, 4th, 5th, and 6th months of the test, the scratch peeling off of the coating and the quality change of the cathodic protection zinc block were tested respectively. Among them, the scratch peeling results of the coating are shown in Table 1 and figure 2 Shown; The mass loss of coated cathodic protection zinc block is shown in Table 2 and image...

Embodiment 2

[0061] At present, in the evaluation of coating protection performance, in addition to macroscopic characterizations such as adhesion, scratches, and cathodic disbondment, electrochemical techniques such as electrochemical impedance spectroscopy can be used to effectively evaluate the relationship between coating water absorption, coating resistance, capacitance, etc. process-related parameters.

[0062] Choose a typical marine anti-corrosion coating - coating system B, coating system B is an inorganic zinc-rich primer + 2 epoxy universal primers.

[0063] Intact samples and scratched samples were prepared respectively. Among them, the intact sample was used to investigate the influence of electrolytic seawater on the permeability of the coating, and the scratched sample was used to investigate the influence of electrolytic seawater on the adhesion of the coating and the corrosion spread of the steel substrate under damaged conditions. Carry out the experiment of step (3)a ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com