Shield segment mechanical simulation test device

A shield segment and simulation test technology, which is applied in the direction of measuring devices, using stable tension/pressure to test material strength, scientific instruments, etc., can solve inaccurate test results, wall damage, and increase the degree of segment damage and other issues to achieve the effect of maintaining flexibility and durability, maintaining flexibility, and ensuring initial non-destructiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

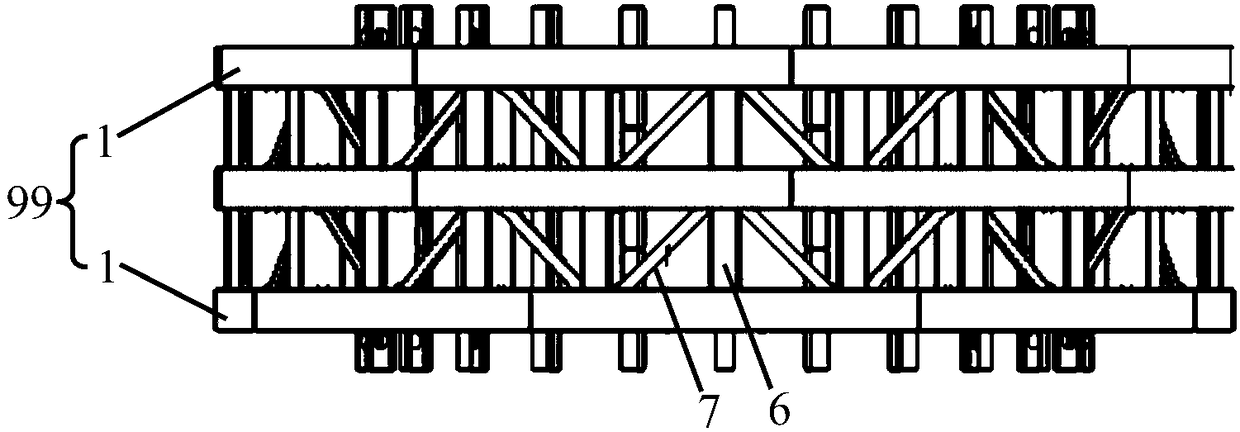

[0039] Such as figure 1 As shown, the present invention firstly provides a mechanical simulation test device for shield tunnel segments, such as figure 1 As shown, the device of the present invention includes a main body reaction force frame 99, ancillary connecting parts, a radial loading mechanism 98, a hydraulic loading device, a sliding type expansion beam 19 and an axial (vertical) loading mechanism. specifically:

[0040] Such as figure 2 As shown, the main body reaction force frame 99 includes multi-layer reaction force ring units 1 arranged at intervals up and down, as the main body structure bearing the test load and the basis for connecting other components, and the adjacent reaction force ring units 1 pass through columns Connected, a plurality of radial loading mechanisms 98 are evenly distributed on the inner wall of the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com