Assembling type ecological pervious concrete retaining wall and preparation method of wall bodies thereof

A technology of permeable concrete and retaining wall, which is applied in the fields of botanical equipment and methods, hydraulic engineering, underwater structures, etc., can solve the problems of high labor cost, long construction period, low construction efficiency, etc., and achieves short construction period, Easy to operate, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

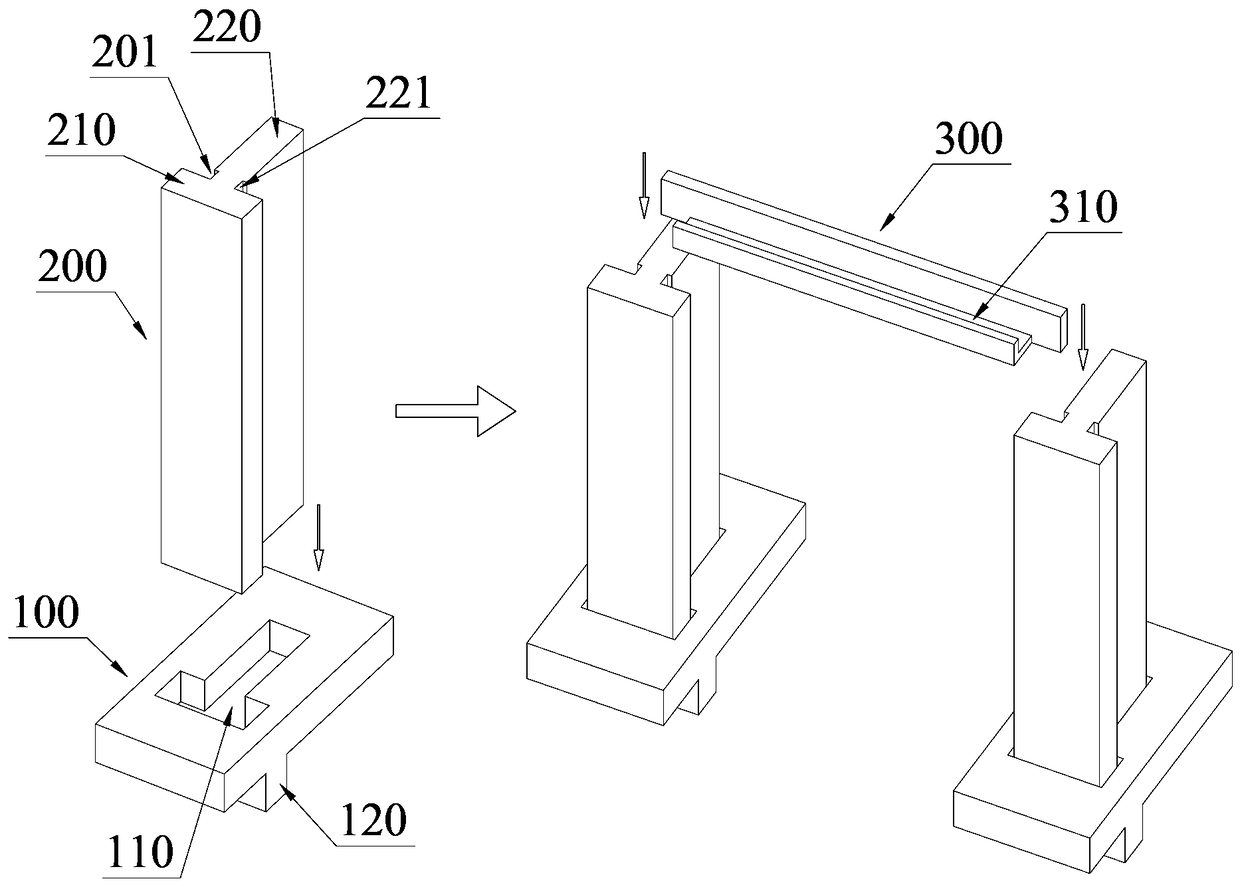

[0054] Such as Figure 1~2 As shown, a prefabricated ecological permeable concrete retaining wall includes a wall 300, a column 200 and a base 100, the two sides of the column 200 are provided with slots 201 for inserting the wall 300, and the bottom of the column 200 passes through the The base 100 is connected to the foundation, and the wall surface of the wall 300 is provided with a boss 310 for planting plants. The wall 300 is composed of an aggregate particle size not greater than 16 mm, a compressive strength greater than 20 MPa, a pore width less than 1 mm, and a water-permeable It is prefabricated with ceramsite permeable concrete with coefficient greater than 5mm and reinforced.

[0055] The ceramsite permeable concrete includes the following components in parts by weight:

[0056] 325 parts of ceramsite with an average particle size of 5-16 mm;

[0057] 375 parts of gravel with an average particle size of 5-10 mm;

[0058] 1.5 parts of organic fibers with an average...

Embodiment 2

[0069] This embodiment is the same as Embodiment 1 except that the components by weight of the ceramsite permeable concrete are different.

[0070] The ceramsite permeable concrete includes the following components in parts by weight:

[0071] 200 parts of ceramsite with an average particle size of 5-16 mm;

[0072] 100 parts of gravel with an average particle size of 5-10mm;

[0073] 1 part of organic fiber with an average length of 4-10mm;

[0074] 230 parts of cement with an average particle size of 30-60 μm and a strength grade of not less than 32.5;

[0075] 80 parts of admixture with an average particle size of 5-30 μm;

[0076] 10 parts of high performance water reducing agent with water reducing rate greater than 25%;

[0077] The water-binder ratio is 0.2.

Embodiment 3

[0079] This embodiment is the same as Embodiment 1 except that the components by weight of the ceramsite permeable concrete are different.

[0080] The ceramsite permeable concrete includes the following components in parts by weight:

[0081] 450 parts of ceramsite with an average particle size of 5-16mm;

[0082] 650 parts of gravel with an average particle size of 5-10mm;

[0083] 2 parts of organic fibers with an average length of 4-10mm;

[0084] 500 parts of cement with an average particle size of 30-60 μm and a strength grade of not less than 32.5;

[0085] 150 parts of admixture with an average particle size of 5-30 μm;

[0086] 15 parts of high-performance water reducing agent with water reducing rate greater than 25%;

[0087] The water-binder ratio is 0.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Water permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com