Material bin anti-bridge device and working method thereof

An anti-bridging and silo technology, applied in the silo anti-bridging device and its working field, can solve the problems of high labor intensity, hollow bottom, and lower material level in the silo, so as to increase safety and controllability , Realize continuous operation and increase the dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

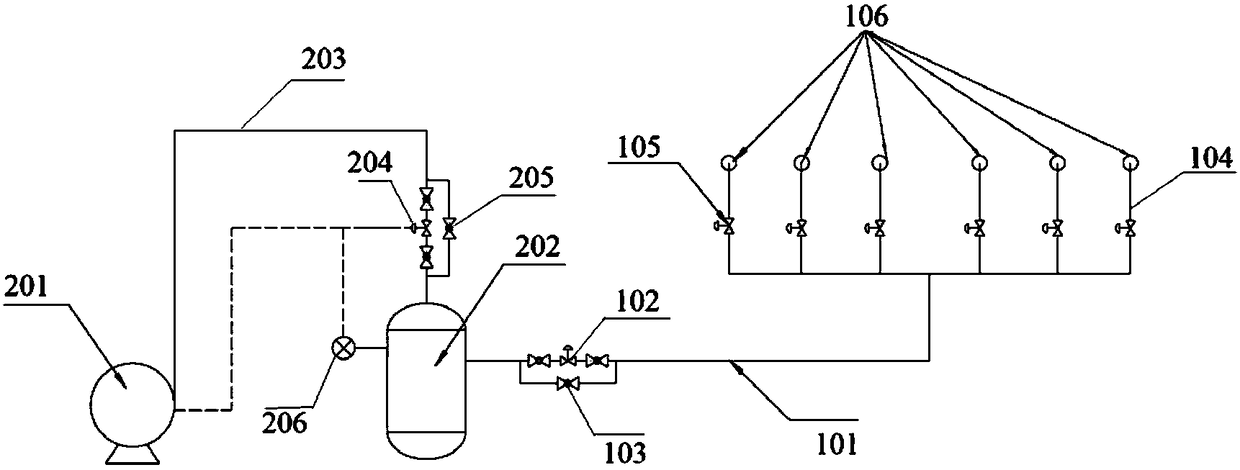

[0030] Embodiment 1: as figure 1 As shown, the silo anti-bridging device of the present invention consists of a spraying device and an air supply device for providing high-pressure gas.

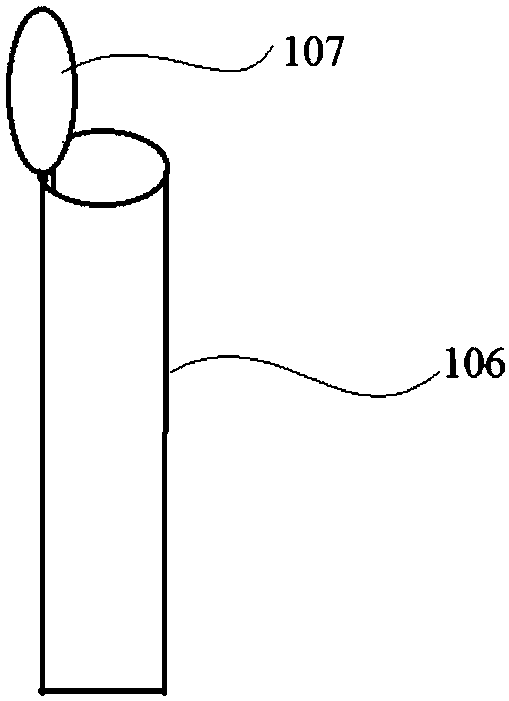

[0031] The injection device includes a first connecting pipe 101, a second electromagnetic valve 102 arranged on the first connecting pipe and connected to a Siemens PLC controller in communication, a first bypass circuit 103, and several bypasses communicated with the gas outlet of the first connecting pipe. The branch pipe 104, the first electromagnetic valve 105 communicated with the controller arranged on the bypass branch pipe, the injection port 106 communicated with the bypass branch pipe, and the cover 107 arranged on the injection port, the injection ports are arranged around the hopper circle.

[0032] The air supply device includes a high-pressure air pump 201 connected in communication with the controller, a high-pressure air storage tank 202, a second connecting pipe 203 connecti...

Embodiment 2

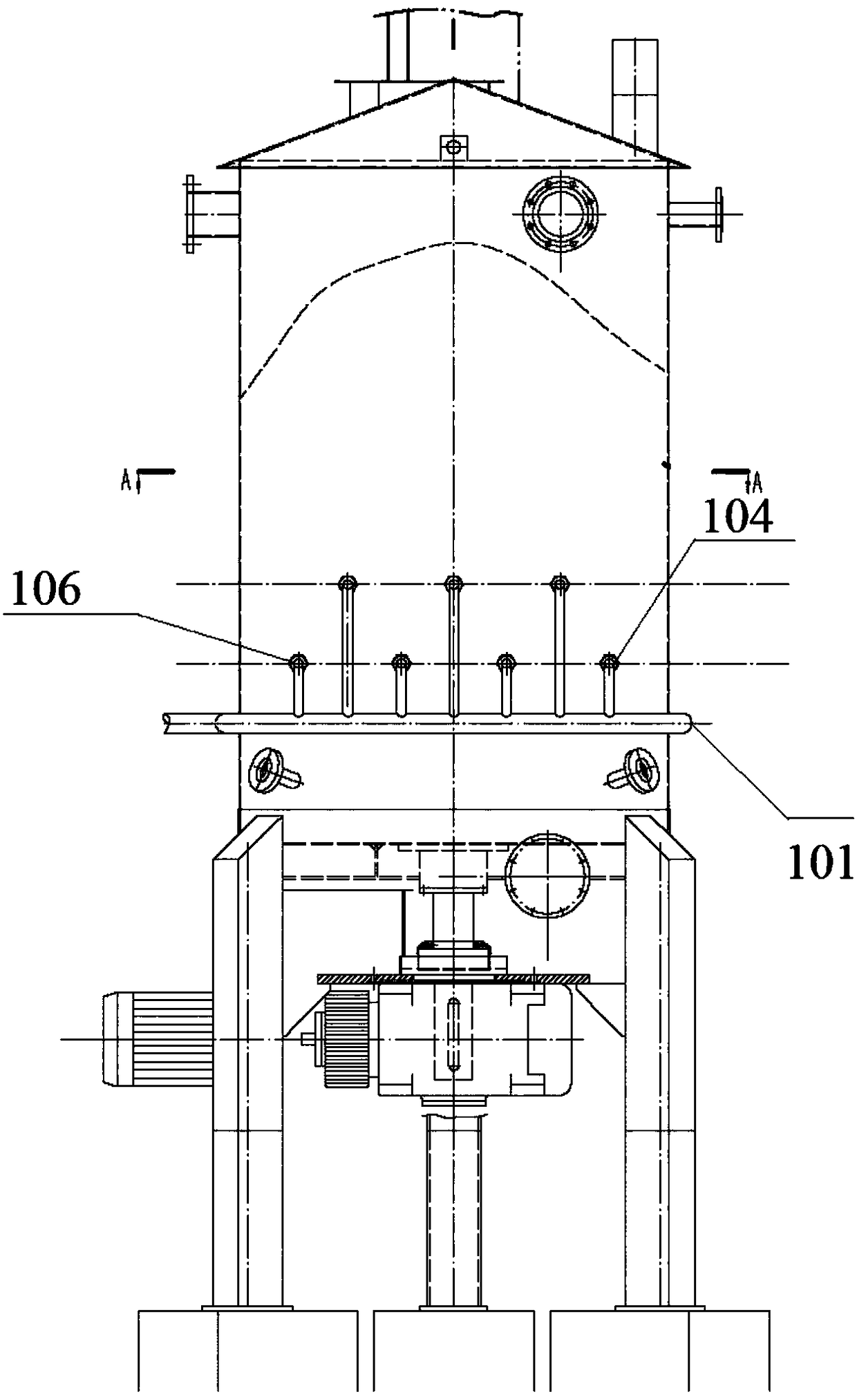

[0033] Embodiment 2: as image 3 , Figure 4 , Figure 5 with Image 6 As shown, the silo anti-bridging device of the present invention consists of a spraying device and an air supply device for providing high-pressure gas.

[0034] The injection device includes a first connecting pipe 101, a second electromagnetic valve 102, a first bypass circuit 103, and a number of bypass branch pipes connected to the gas outlet of the first connecting pipe, which are arranged on the first connecting pipe and communicate with the Siemens PLC controller. 104. The first electromagnetic valve 105, which is arranged on the bypass branch pipe and communicates with the controller, the injection port 106 communicated with the bypass branch pipe, and the cover 107 arranged on the injection port. The injection ports are arranged in two circles around the silo. Floor.

[0035] The air supply device includes a high-pressure air pump 201 connected in communication with the controller, a high-press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com