Waste material collection device of CNC high-speed machining center

A waste collection, high-speed technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of shortening the mold manufacturing cycle, reducing processing time, labor-intensive transportation, etc., and achieve good economic and social benefits, Prevent damage to the base frame and save time and labor in transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

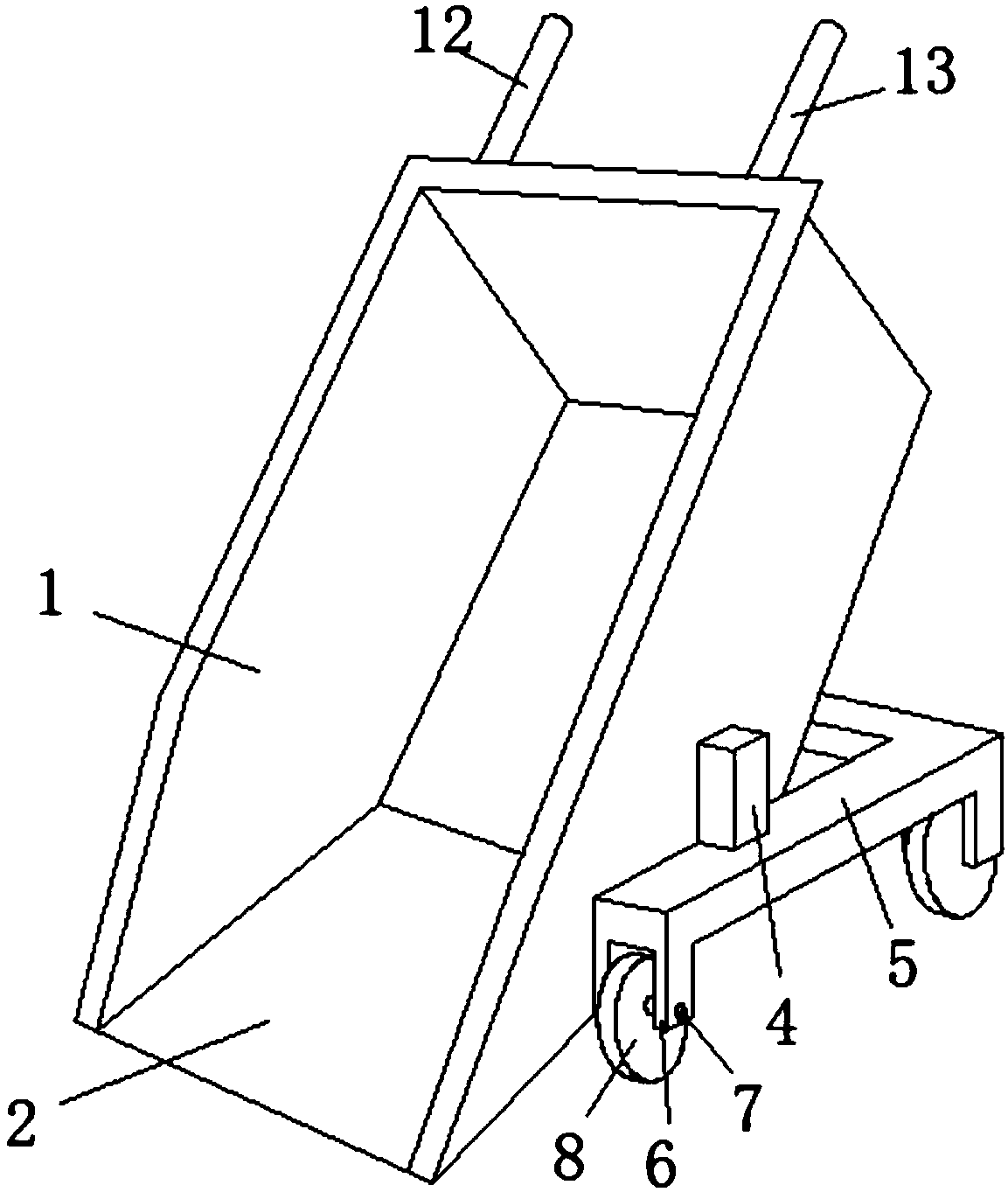

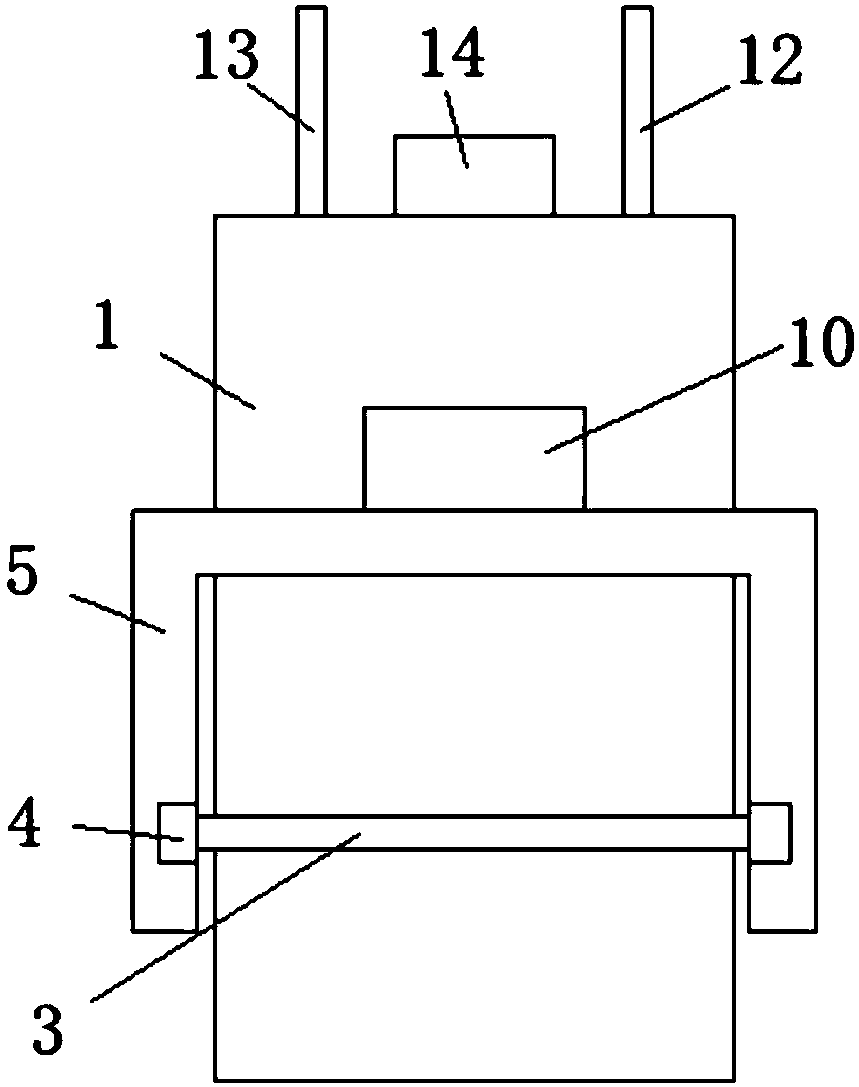

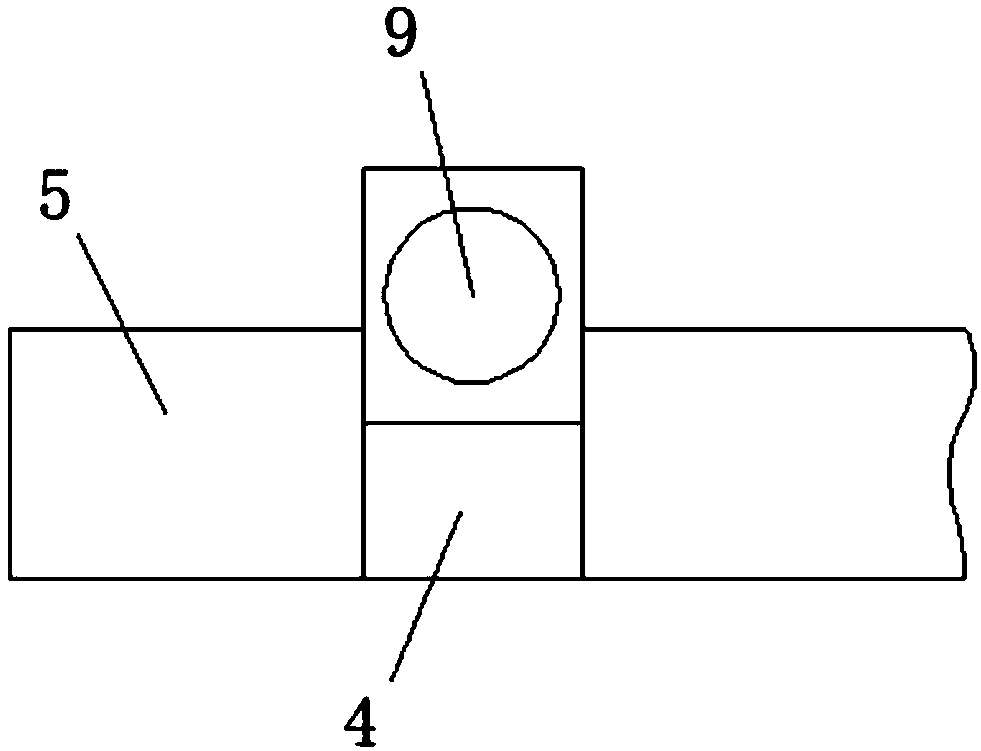

[0018] Example: such as Figure 1-5 As shown, the present invention provides a waste collection device for a CNC high-speed machining center, including a collection bucket 1 and a base frame 5, the base frame is located below the collection bucket 1, and one side of the collection bucket 1 is provided with a collection front Nozzle 2, the bottom of the collection bucket 1 is fixedly connected to the flipping horizontal shaft 3, and the side of the flipping horizontal shaft 3 is provided with a horizontal shaft rotating shaft 9 and a lifting fixed rod 4, and the horizontal shaft rotating shaft 9 is located inside the lifting fixed rod 4 , one side of the lifting and fixing rod 4 is provided with a base frame 5, and one side of the base frame 5 is provided with a roller fixing frame 6 and a roller rotating shaft 7, and the roller rotating shaft 7 is located inside the roller fixing frame 6, and the roller rotates A roller 8 is arranged on one side of the shaft 7, an auxiliary po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com