Hardware plate laminating auxiliary equipment

A technology of auxiliary equipment and plates, applied in the direction of material gluing, mechanical equipment, presses, etc., can solve the problems of low lamination efficiency, insufficient lamination, complicated operation, etc., and achieve the effect of lamination and smoothness of plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

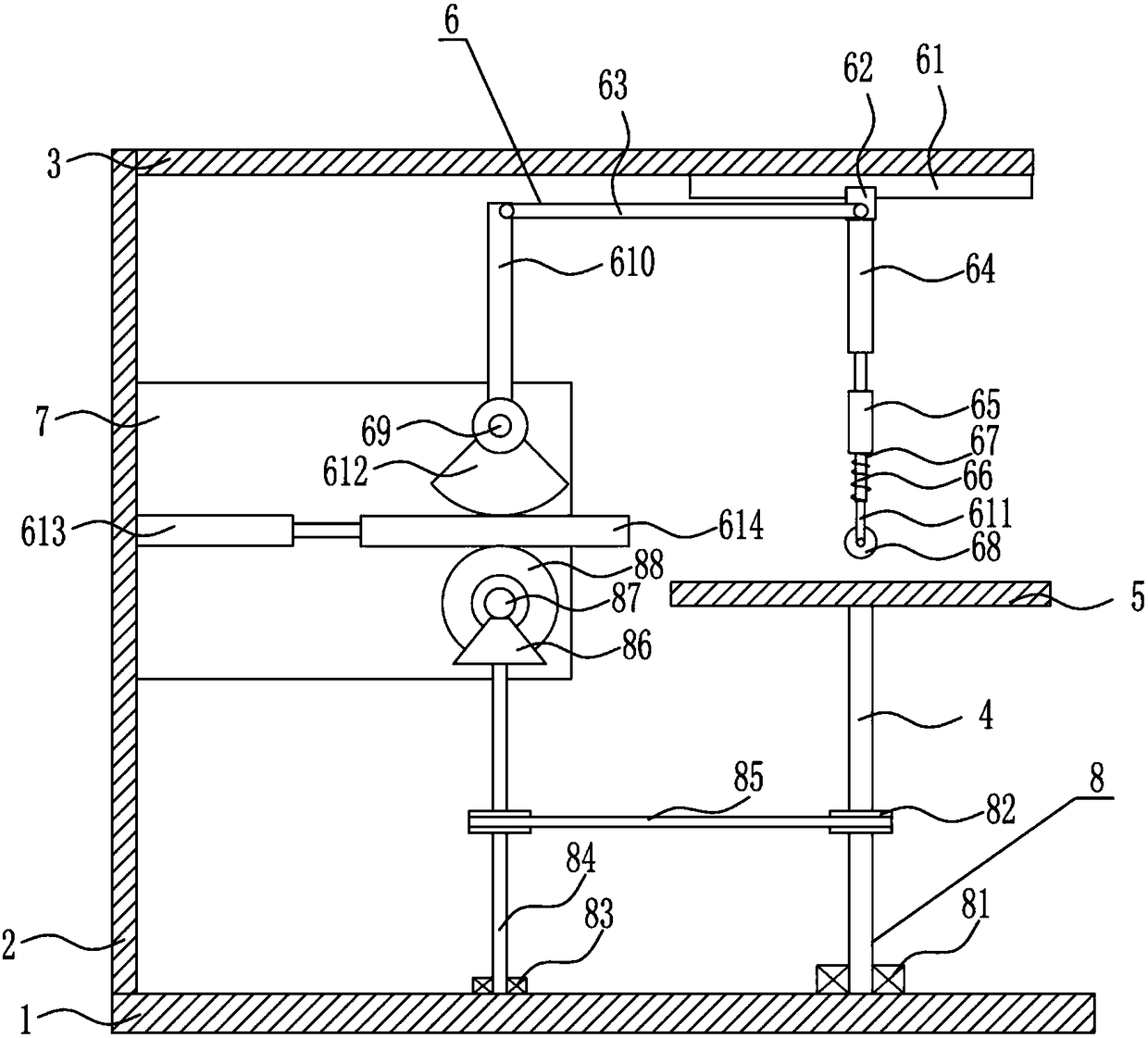

[0029] An auxiliary equipment for pressing metal sheets, such as Figure 1-4As shown, it includes bottom plate 1, left bracket 2, top plate 3, vertical rod 4, placement plate 5, pressing mechanism 6, fixing plate 7 and rotation mechanism 8, left bracket 2 on the top left side of bottom plate 1, and left side on the top side of bottom plate 1. A left bracket 2 is provided, a vertical bar 4 is provided on the right side of the top of the base plate 1, a placement plate 5 is provided at the top of the vertical bar 4, a fixed plate 7 is provided at the middle part of the right side of the left support 2, and a rotating mechanism 8 is provided below the fixed plate 7. A top plate 3 is provided on the upper right side of the bracket 2 , and a pressing mechanism 6 is provided below the top plate 3 .

Embodiment 2

[0031] An auxiliary equipment for pressing metal sheets, such as Figure 1-4 As shown, it includes bottom plate 1, left bracket 2, top plate 3, vertical rod 4, placement plate 5, pressing mechanism 6, fixing plate 7 and rotation mechanism 8, left bracket 2 on the top left side of bottom plate 1, and left side on the top side of bottom plate 1. A left bracket 2 is provided, a vertical bar 4 is provided on the right side of the top of the base plate 1, a placement plate 5 is provided at the top of the vertical bar 4, a fixed plate 7 is provided at the middle part of the right side of the left support 2, and a rotating mechanism 8 is provided below the fixed plate 7. A top plate 3 is provided on the upper right side of the bracket 2 , and a pressing mechanism 6 is provided below the top plate 3 .

[0032] The pressing mechanism 6 includes a slide rail 61, a slide block 62, a connecting rod 63, a cylinder 64, a sleeve 65, a sleeve rod 66, a first spring 67, a roller 68, a first ro...

Embodiment 3

[0034] An auxiliary equipment for pressing metal sheets, such as Figure 1-4 As shown, it includes bottom plate 1, left bracket 2, top plate 3, vertical rod 4, placement plate 5, pressing mechanism 6, fixing plate 7 and rotation mechanism 8, left bracket 2 on the top left side of bottom plate 1, and left side on the top side of bottom plate 1. A left bracket 2 is provided, a vertical bar 4 is provided on the right side of the top of the base plate 1, a placement plate 5 is provided at the top of the vertical bar 4, a fixed plate 7 is provided at the middle part of the right side of the left support 2, and a rotating mechanism 8 is provided below the fixed plate 7. A top plate 3 is provided on the upper right side of the bracket 2 , and a pressing mechanism 6 is provided below the top plate 3 .

[0035] The pressing mechanism 6 includes a slide rail 61, a slide block 62, a connecting rod 63, a cylinder 64, a sleeve 65, a sleeve rod 66, a first spring 67, a roller 68, a first ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com