Nano hot stamping device

A hot embossing and nanotechnology, applied in optics, opto-mechanical equipment, instruments, etc., can solve the problems of unevenness, unbalanced force, uneven surface, etc., and achieve the effect of stable product quality, low cost and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

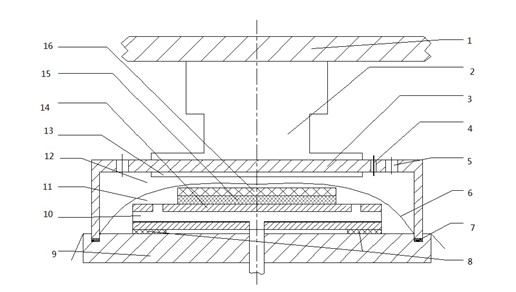

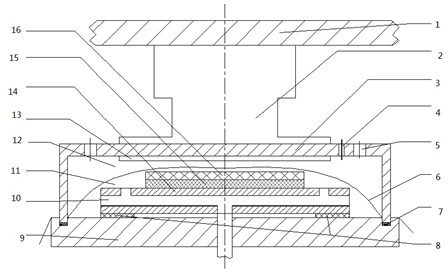

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0017] As shown in the drawings, the nano-thermal embossing device of the present invention includes a mold 16, a blank 15, a heating plate 14, a base 9, and a cavity 3. The heating plate 14 is placed on the base 9, and the blank 15 is placed on the heating plate 14. The mold 16 is placed on the blank 15, the cavity 3 and the base 9 are movably sealed to form an airtight space, the mold 16, the blank 15 and the heating plate 14 are enclosed in the airtight space, and a film 6 is also arranged in the cavity 3, and the film 6 It is fixed at the sealed contact surface between the cavity body 3 and the base 9, and the closed space formed by the cavity body and the base is divided into a pressure cavity 12 and a vacuum cavity 11, the pressure cavity 12 communicates with the air inlet 5, and the vacuum cavity 11 communicates with the exhaust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com