Spot-jet cooling ring and wheel hub mould with spot-jet cooling ring

A technology of cooling ring and spot spraying, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of cumbersome processing, complex water flow pipeline structure, and increased processing costs of multi-point combined cooling devices, and achieve simplified processing operations, The effect of reducing processing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

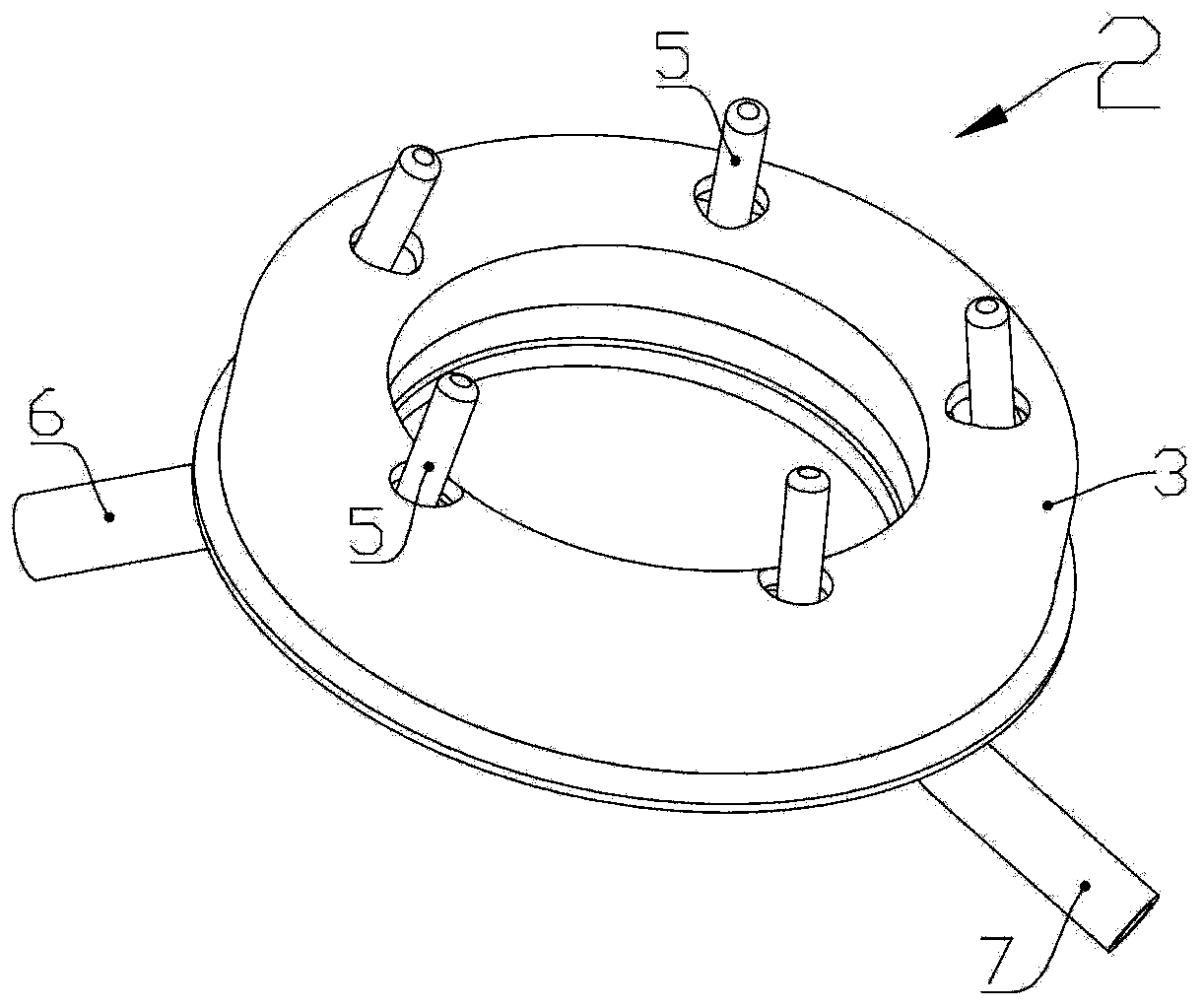

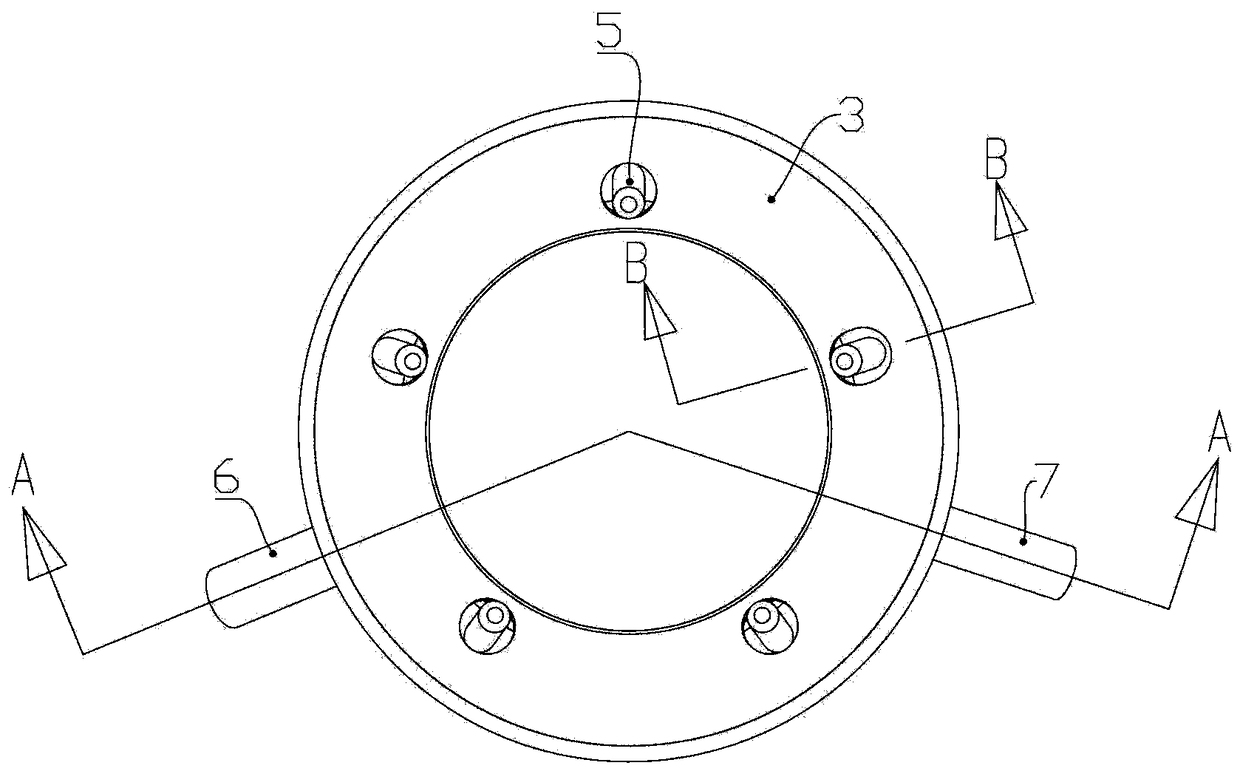

[0024] The structure of the spot-spray cooling ring and the wheel hub mold applied to the technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] Such as figure 1As shown, the hub mold 100 using the spot spray cooling ring 2 includes an upper mold 1 and a lower mold 12 separated from the upper and lower, and a side mold 11 arranged between the upper mold 1 and the lower mold 12. The upper mold 1, the lower mold 12 and the side mold 11 enclose the hub cavity 10, and the lower mold 12 is provided with a gate 13 for inputting raw material melt, and the gate 13 communicates with the hub cavity 10, At least one pair of protruding pillars 121 (also known as PCD pillars) are arranged on the upper peripheral wall of the gate 13 , and all the protruding pillars 121 extend upward and are arranged around the gate 13 . On the lower side wall of the lower mold 12, there is a closed ring-shaped accommodation pit (i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com