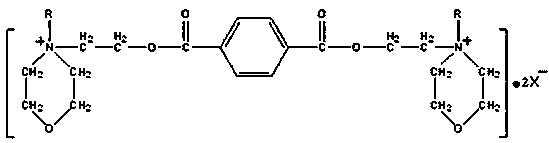

A kind of cationic surfactant prepared by using waste polyester and its preparation method

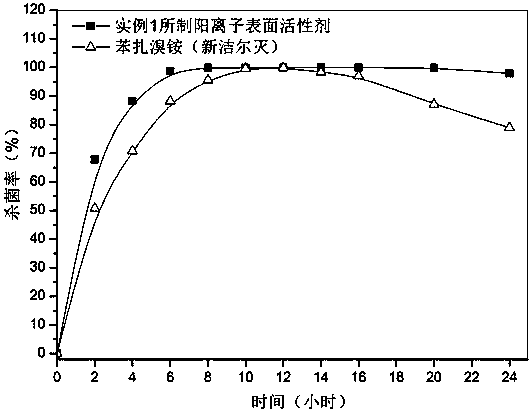

A surfactant and waste polyester technology, applied in chemical instruments and methods, organic chemistry, dissolution, etc., can solve the problems of narrow product application fields, low yield of polyester alcoholysis, etc., and achieve high surface activity and sterilization/ Antibacterial ability, low cost of raw materials, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0023] (1) Alcoholysis of waste polyester: First, wash the waste polyester with deionized water at 60°C, then break it into pieces with a length of 2mm, and then dry it at 90°C for 2 hours to remove water and volatiles. Then 500g of waste polyester chips, 1250g of ethylene glycol and 10g of stannous chloride and manganese acetate mixed catalyst (mass ratio of stannous chloride and manganese acetate is 20:80) were added in turn to the connected thermometer, stirrer and condensing In the reactor of the tube, the temperature was raised to 198° C. under the condition of nitrogen protection, and the reaction was carried out for 1 h. When approaching the end of the reaction, take a small amount of reactants every 10 minutes and put them in a 1:1 mixed solution with a volume ratio of xylene and n-octane. If the mixed solution is clear and there is no suspended matter, stop the reaction. After cooling, filter, add deionized water to recrystallize three times, put the product in a vacu...

example 2

[0036] (1) Alcoholysis of waste polyester: First, wash the waste polyester with deionized water at 60°C, then break it into pieces with a length of 2mm, and then dry it at 90°C for 2 hours to remove water and volatiles. Then 500g of waste polyester chips, 1250g of ethylene glycol and 10g of stannous chloride and manganese acetate mixed catalyst (mass ratio of stannous chloride and manganese acetate is 40:60) were added in turn to the connected thermometer, stirrer and condensing In the reactor in the tube, the temperature was raised to 198° C. under nitrogen protection, and the reaction was carried out for 1 h. When approaching the end of the reaction, take a small amount of reactants every 10 minutes and put them in a 1:1 mixed solution with a volume ratio of xylene and n-octane. If the mixed solution is clear and there is no suspended matter, stop the reaction. After cooling, filter, add deionized water to recrystallize three times, put the product in a vacuum oven at 60°C, ...

example 3

[0040] (1) Alcoholysis of waste polyester: First, wash the waste polyester with deionized water at 60°C, then break it into pieces with a length of 2mm, and then dry it at 80°C for 3 hours to remove water and volatiles. Then 500g of waste polyester chips, 1250g of ethylene glycol and 15g of stannous chloride and manganese acetate mixed catalyst (mass ratio of stannous chloride and manganese acetate is 20:80) were added in turn to the connected thermometer, stirrer and condensing In the reactor in the tube, the temperature was raised to 198° C. under nitrogen protection, and the reaction was carried out for 1 h. When approaching the end of the reaction, take a small amount of reactants every 10 minutes and put them in a 1:1 mixed solution with a volume ratio of xylene and n-octane. If the mixed solution is clear and there is no suspended matter, stop the reaction. After cooling, filter, add deionized water to recrystallize three times, put the product in a vacuum oven at 60°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

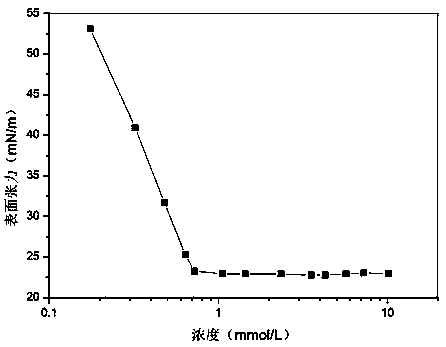

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com