Equipment for pouring acid for horizontal batteries

A horizontal battery and acid filling technology, which is applied to battery components, circuits, electrical components, etc., can solve problems affecting the normal use of batteries, leakage, etc., and achieve the effect of shortening the time of acid filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

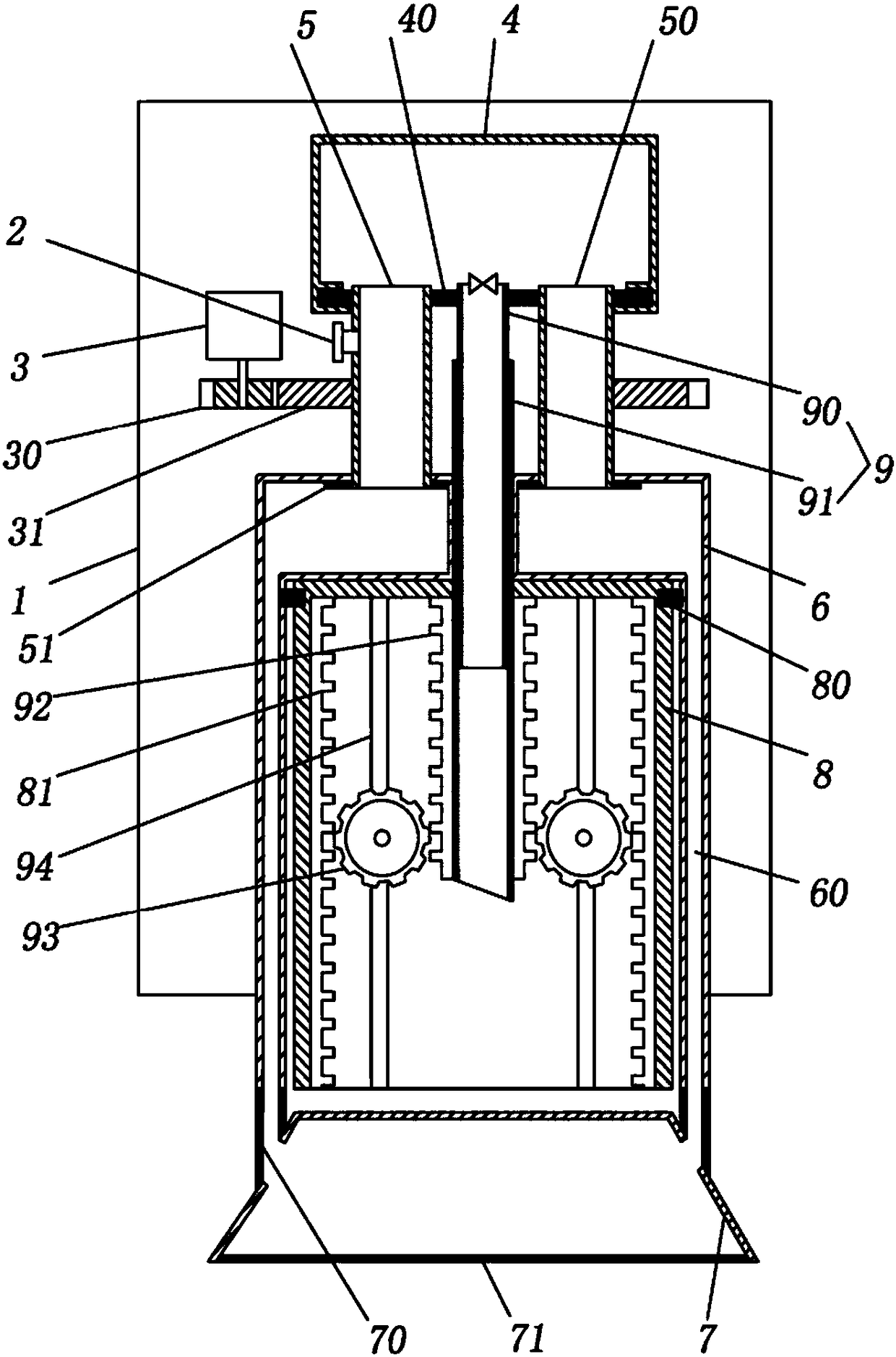

[0019] Further detailed explanation through specific implementation mode below:

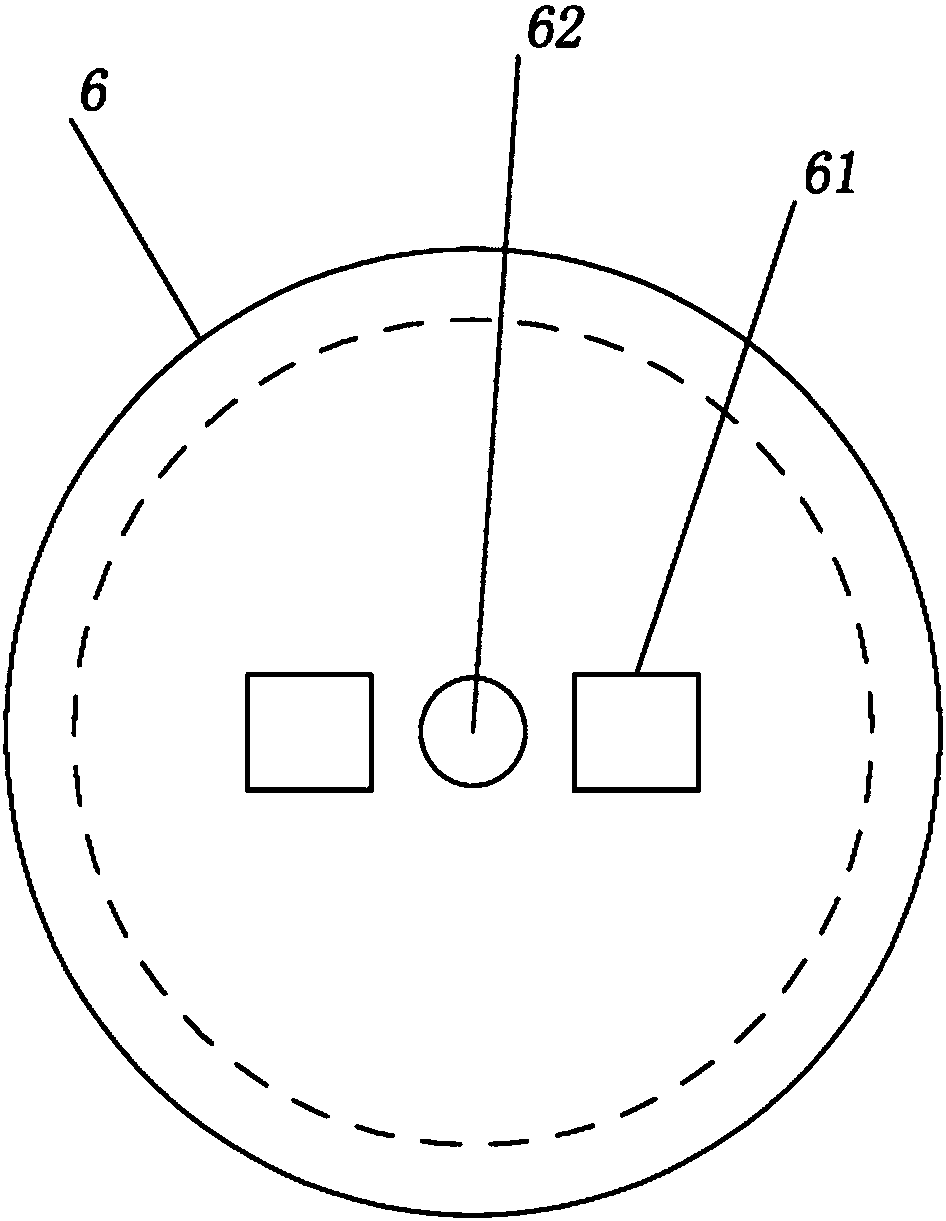

[0020] The reference signs in the accompanying drawings of the description include: frame 1, vacuum pump 2, motor 3, driving gear 30, driven ring gear 31, electrolyte tank 4, sealing plate 40, fixed tube one 5, fixed tube two 50, limiter Bit block 51, sliding cover 6, liquid-absorbing interlayer 60, square opening 61, circular through-hole 62, liquid-dispersing part 7, catheter 70, filter 71, inner cylinder cover 8, swivel 80, rack 1 81 , acid filling pipe 9, inner casing 90, outer casing 91, rack two 92, rotating gear 93, shaft seam 94, acid filling mouth 100.

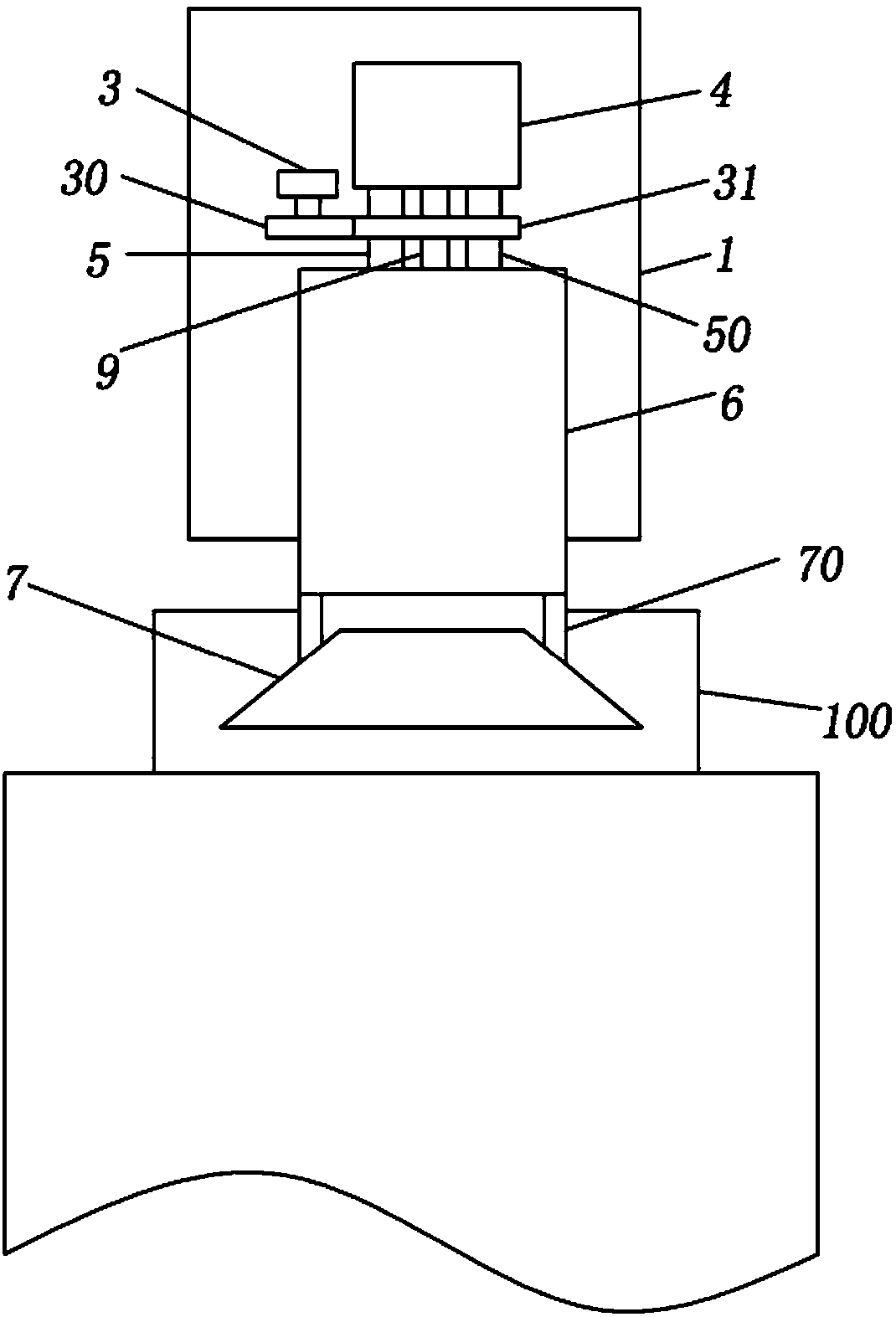

[0021] The embodiment is basically as attached figure 1 Shown: horizontal battery acid filling equipment, including frame 1, driving mechanism, vacuum pump 2, electrolyte tank 4, acid filling pipe 9 and acid suction mechanism. The electrolyte tank 4 is fixed on the frame 1.

[0022] Such as figure 2 As shown, the acid suction mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com