Bridge surface crack detection device

A detection device, a technology for surface cracks, used in measurement devices, elasticity testing, machine/structural component testing, etc., which can solve problems such as efficiency that is easily affected by subjective factors, easy to be affected by weather changes, and difficult to guarantee results. , to achieve the effect of convenient and targeted treatment, reducing labor intensity and operation risk, and reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in conjunction with the following application scenarios.

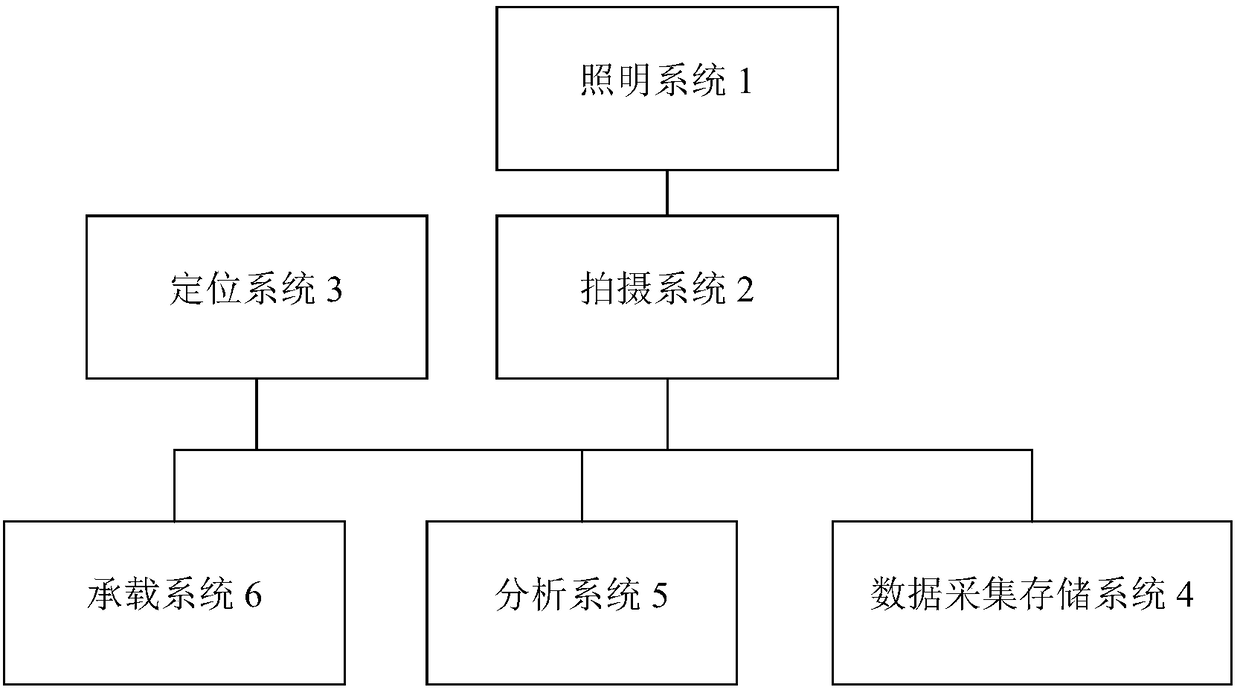

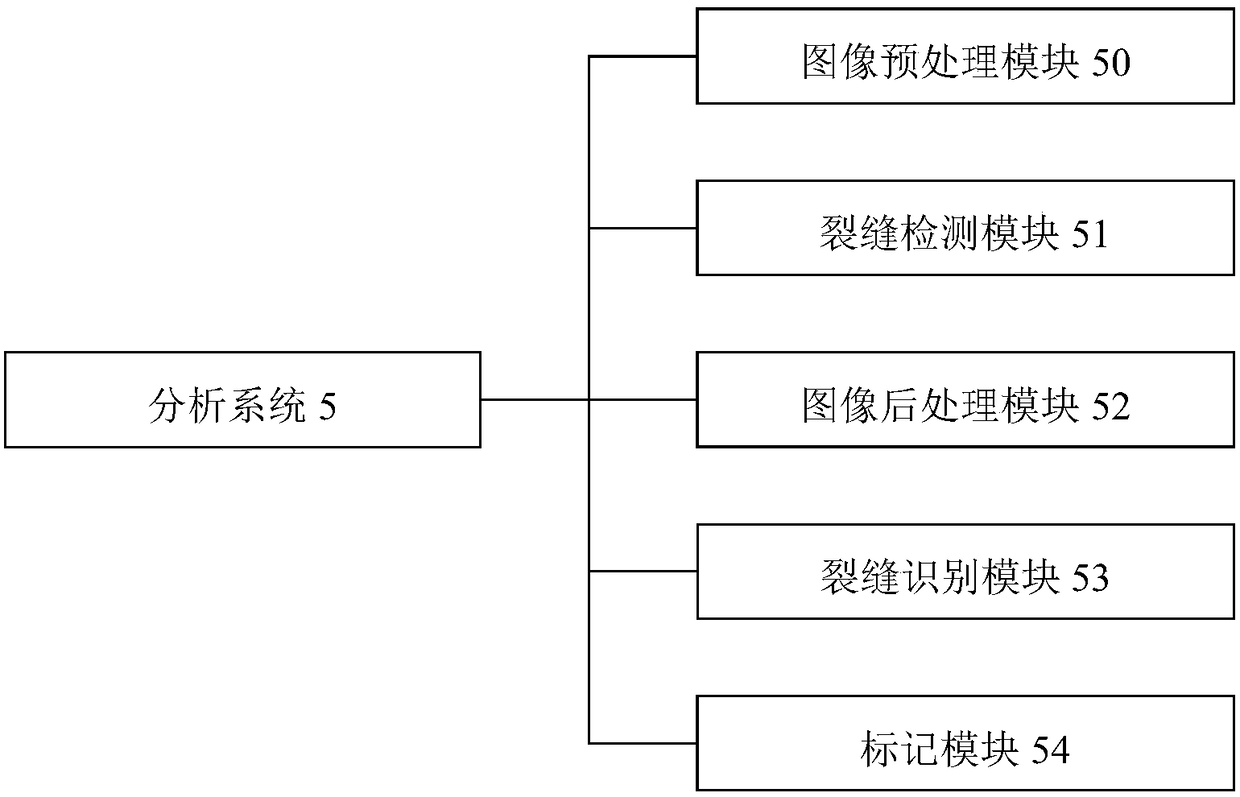

[0016] see figure 1 , a bridge surface crack detection device, comprising: a lighting system 1, used to provide lighting for the bridge surface to be detected; a shooting system 2, installed in a protective cover, for cooperating with the lighting system 1 to collect bridge surface images; positioning System 3 is installed on the carrying system 6 to determine the position of the defect on the bridge; the data acquisition and storage system 4 is used to receive the bridge surface image and defect location information collected in real time and record them on the hard disk; the analysis system 5 uses To carry out real-time analysis on the bridge surface images collected by the shooting system 2, and detect whether there are cracks on the bridge surface; the carrying system 6, including the wall climbing robot, is used to carry the lighting system 1, the shooting sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com