A shock absorber damping regulating valve

A damping adjustment and shock absorber technology, which is applied in the field of damping adjustment valves, can solve the problems of high cost of magneto-rheological fluid, reduced maneuverability, and difficult control, so as to expand the range of damping adjustment, facilitate manufacturing and installation, and reduce manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following embodiments given in conjunction with the accompanying drawings illustrate the present invention in further detail, but are not intended to limit the present invention.

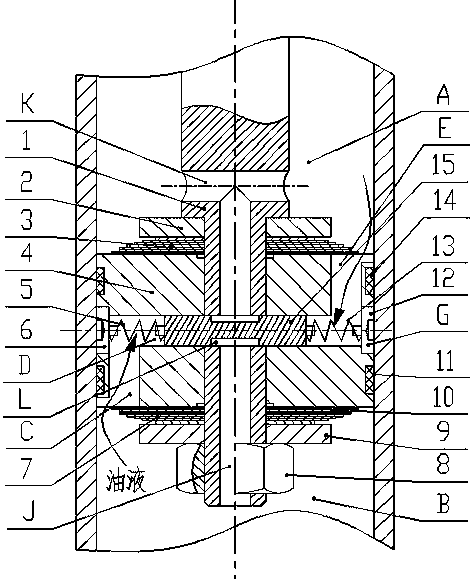

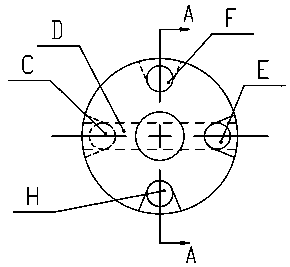

[0017] Such as Figure 1 to Figure 2 As shown, the embodiment of the present invention discloses a shock absorber damping regulating valve mainly comprising: a piston rod 1, a piston assembly and a valve assembly. The piston assembly includes a piston 4, a left spring 5, a left spring positioning seat 6, a lower sealing ring 10, a lower sealing ring 11, a right spring positioning seat 12, a right spring 13, an upper sealing ring 14, etc.; the valve assembly includes an upper limit Bit block 2, circulation valve group 3, recovery valve group 7, fastening nut 8, lower limit block 9, throttle valve core 15. The piston rod 1 includes a first piston rod 1-1 and a second piston rod 1-2. The piston 4 is installed on the second piston rod 1-2. The piston 4 divides the shock absorber working cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com