LNG underground tank base plate anti-floating decompression structure and construction thereof

A technology for underground storage tanks and base plates, which is applied in infrastructure engineering, construction, protection devices, etc., can solve the problems of high cost of anti-pulling anchor pile engineering, increasing the thickness of the base plate, and short construction period, so as to achieve a short construction period and reduce Crack resistance requirements, the effect of reducing the floatover force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

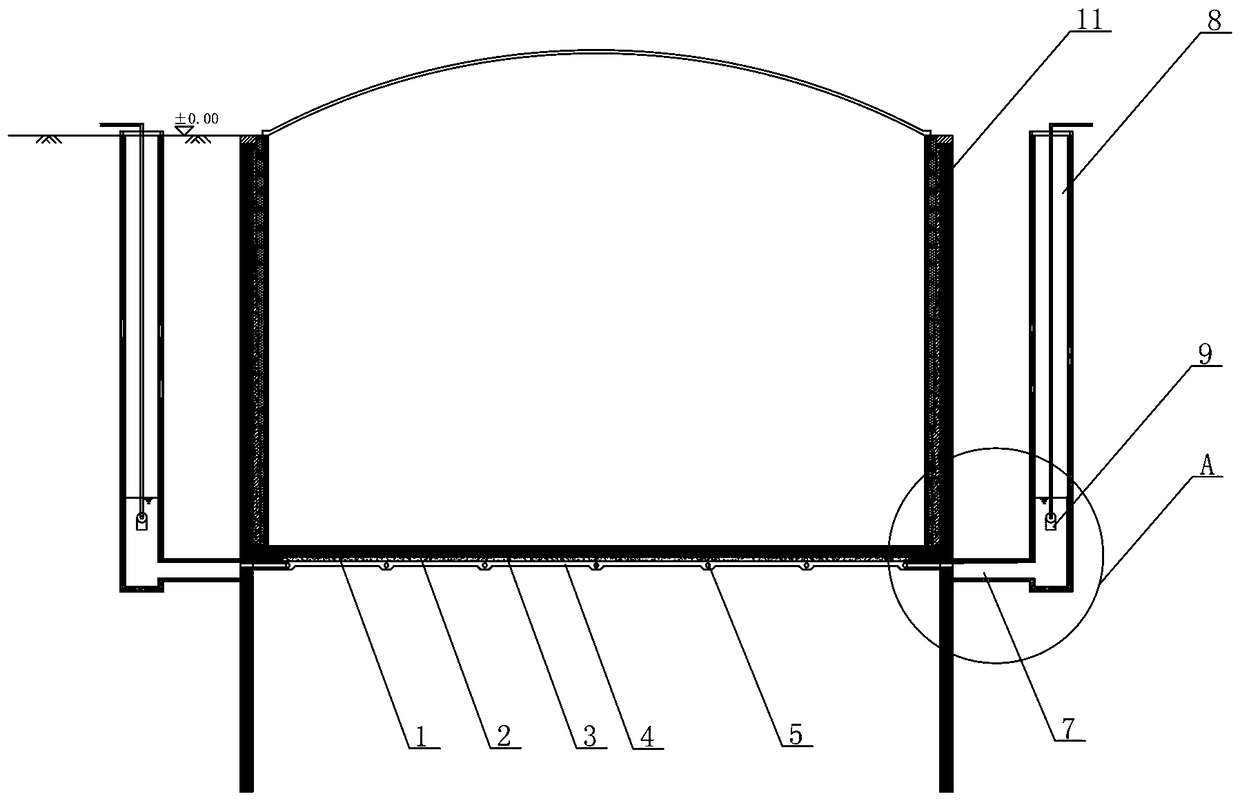

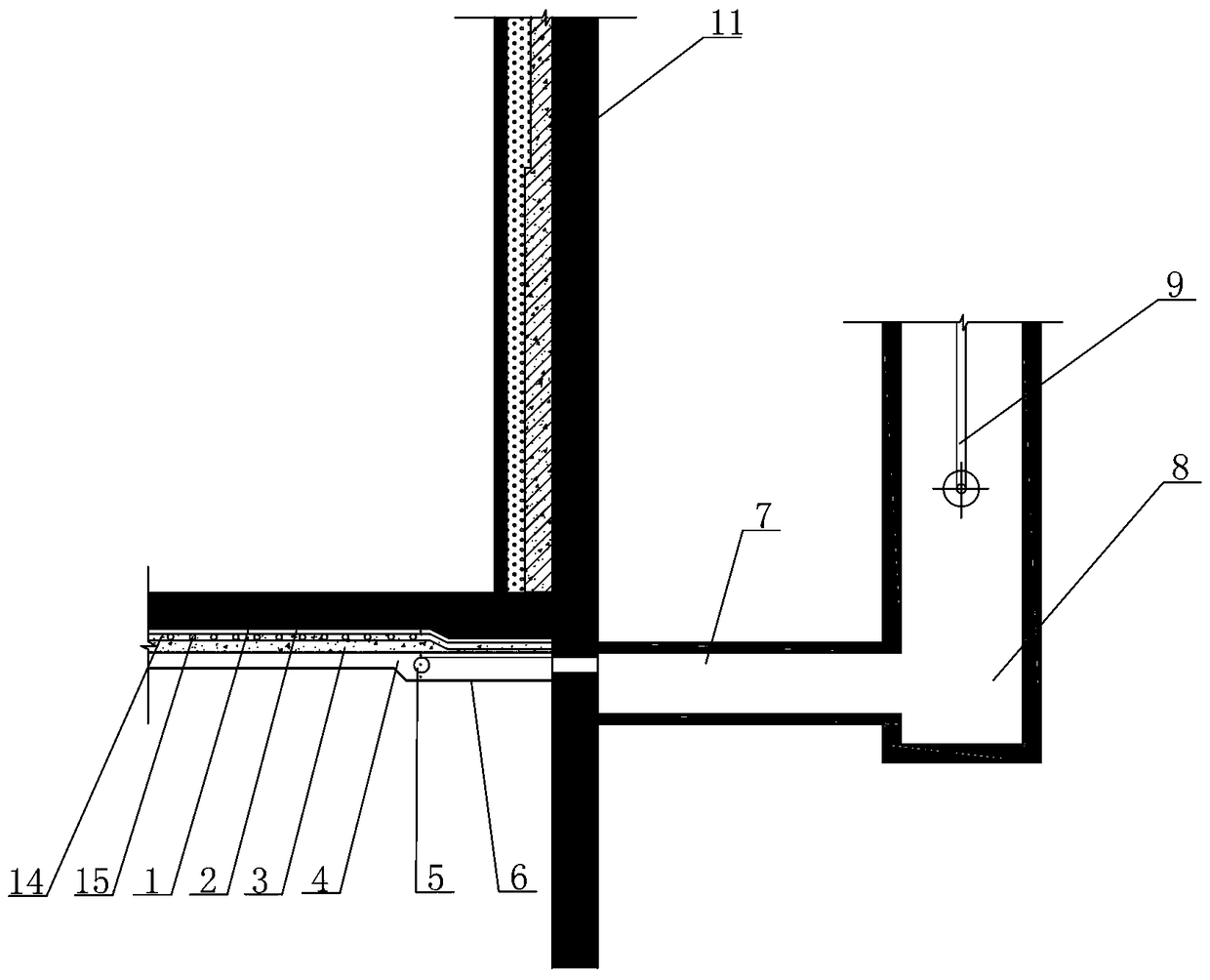

[0028] See attached image 3 , the project is a soil foundation, the vertical and horizontal spacing of the drainage pipes 12 is 12m, the thickness of the hydrophobic layer 4 is 600mm, and the drainage pipe 5 is set in the hydrophobic layer 4, and the underground seepage is collected through the drainage pipe 12 by the drainage channel 7 to the outside of the storage tank 11 After the water collecting well 8, the submersible pump 9 discharges the drainage pipe network 5, and its specific construction steps are as follows:

[0029] (1) Laying of permeable geotextiles

[0030] See attached figure 1 , excavated until the design elevation of the base plate 1 is -52.50m, the base surface is trimmed, and the permeable geotextile 6 is laid after meeting the flatness requirements. 6 is not destroyed.

[0031] (2) Laying of hydrophobic layer and installation of drainage pipes

[0032] A hydrophobic layer 4 of graded crushed stones is set on the permeable geotextile 6. The thickness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com