Internal mixer cleaning material and preparation method thereof

A technology of internal mixer and cleaning material, which is applied in the field of internal mixer cleaning material and its preparation, can solve the problems of yellowing and blackening, and achieve the effects of easy demoulding, convenient and quick cleaning, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

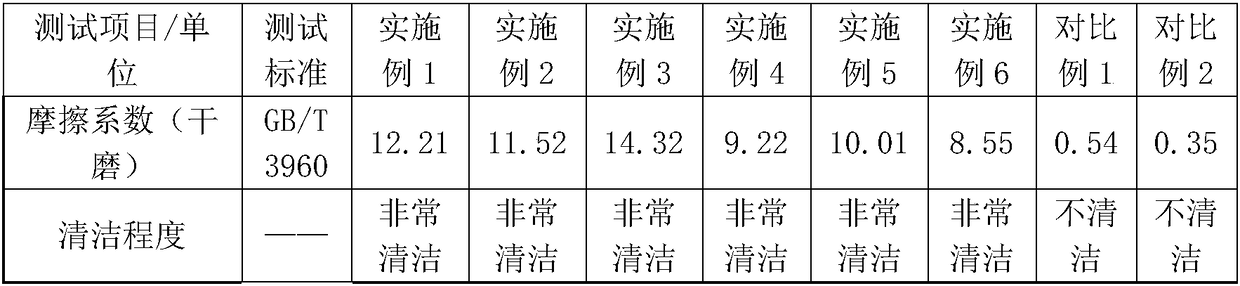

Examples

Embodiment 1

[0026] Weigh 15 parts of PP, 85 parts of ceramic powder, 0.2 part of antioxidant 1010, and 0.4 part of calcium stearate according to the mass ratio; put the weighed raw materials into a banburying mixer with a volume of 50L for banburying, banburying The set temperature of the machine is 20°C, and the banburying time is 30 minutes; the mass-mixed material is transported to the conical twin-single-screw extruder with a screw diameter of 180cm, and is melted, mixed and extruded by the single-screw extruder , and then pelletized to make cleaning material for internal mixer.

Embodiment 2

[0028] Weigh 15 parts of PE according to the mass ratio, weigh 85 parts of illite powder (Guangdong Tiangao Mining Industry), 0.1 part of antioxidant dioctadecyl thiodipropionate, and 0.3 part of zinc stearate; weigh the raw materials Put it into the internal mixer with a volume of 150L for internal mixing. The temperature of the internal mixer is set at 25°C, and the internal mixing time is 15 minutes; In the screw extruder, it is melted, kneaded and extruded by a single-screw extruder, and then pelletized to make cleaning material for the internal mixer.

Embodiment 3

[0030] Weigh 20 parts of PP, 80 parts of corundum powder, 0.1 part of antioxidant 1010, 0.1 part of dioctadecyl thiodipropionate, and 0.2 part of oleic acid according to the mass ratio; Banbury mixing in a mixer with a volume of 250L, the set temperature of the mixer is 30°C, and the mixing time is 20 minutes; the mixed dough is transported to the cone twin-single-screw extrusion with a screw diameter of 180cm In the machine, it is melted, kneaded and extruded by a single-screw extruder, and then pelletized to make cleaning material for the internal mixer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com