3D printer

A 3D printer and printing cavity technology, applied in the field of 3D printing, can solve the problem that the batch processing technology is rarely studied, and achieve the effect of convenient small batch 3D printing and small displacement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

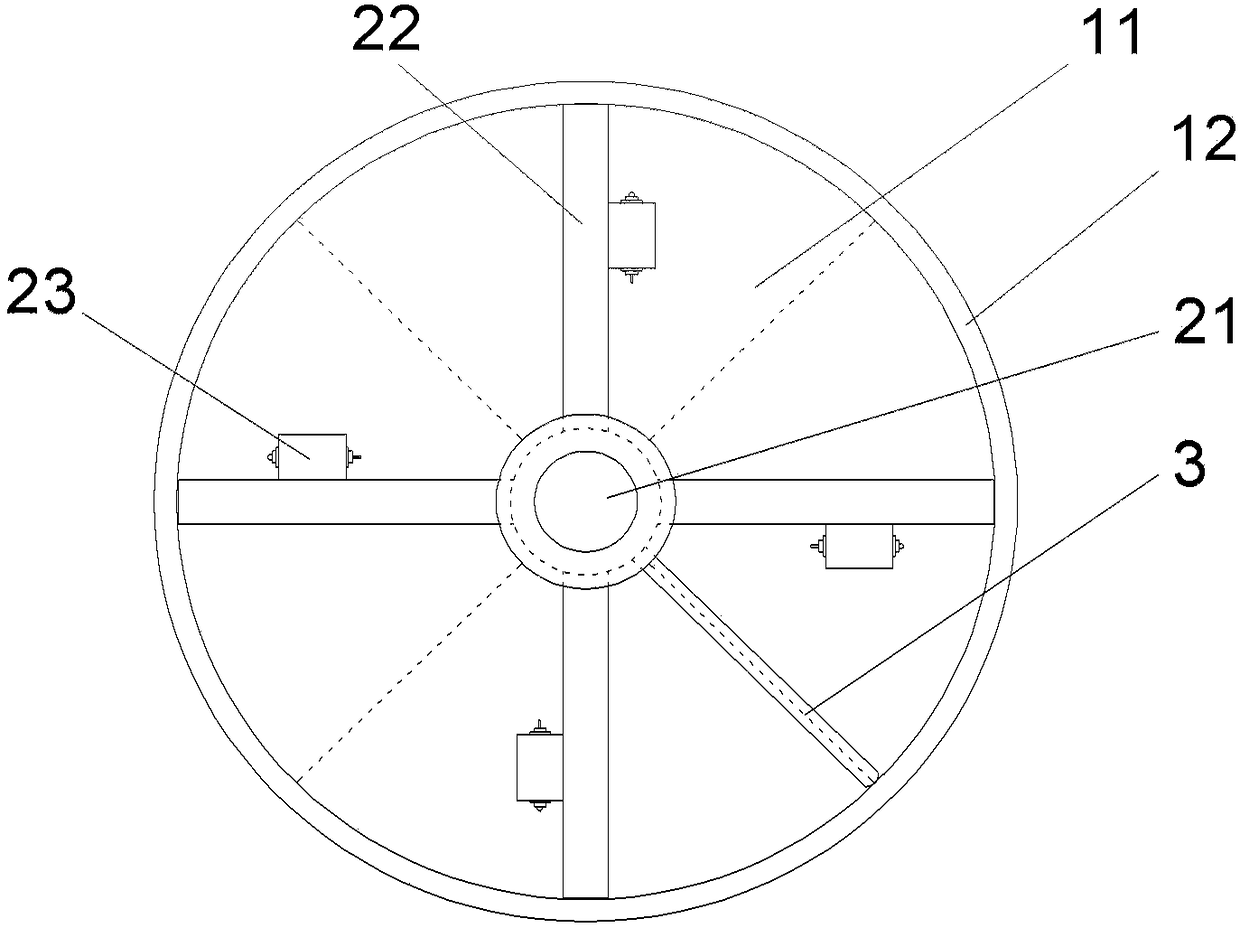

[0049] The application provides a 3D printer. Each printing station is arranged in a ring shape, and the processing part is set above the printing station. The push rod can level each printing station at one time, and the processing parts can be linked with each other, with good synchronization, high precision and simple control.

[0050] In order to make the purpose, technical solutions and advantages of the present application clearer, the present application will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

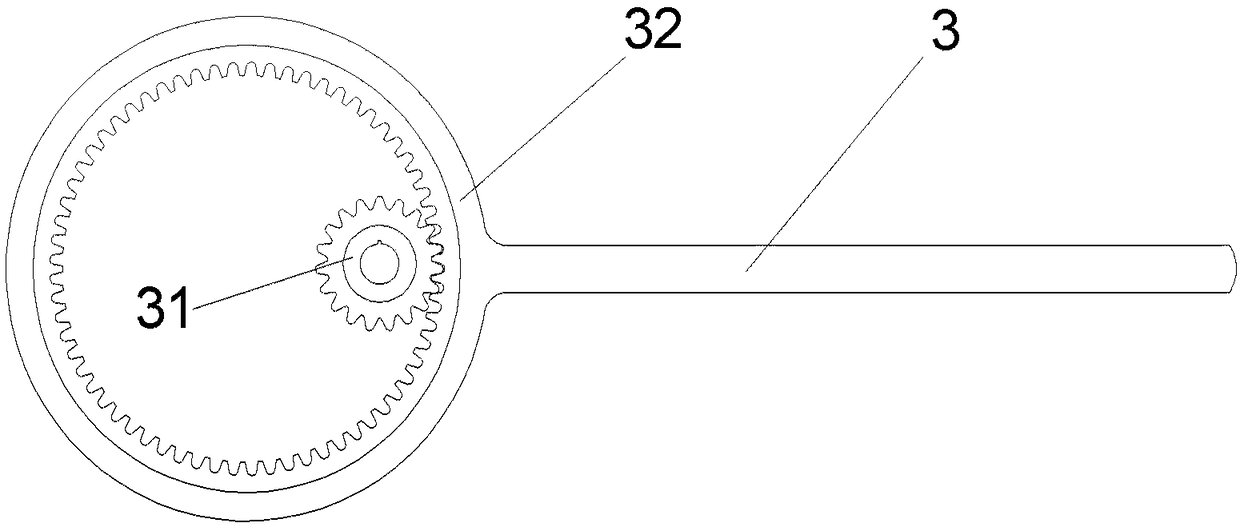

[0051] In an exemplary embodiment of the present application, a 3D printer is provided. Such as figure 1 , figure 2 As shown, the application includes a printing chamber, a push rod 3 and a processing part 23, and the processing part 23 includes a column 21 and a machine head.

[0052] Each component of this embodiment will be described in detail below.

[0053] The printing chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com