Wall-climbing type shot blasting robot

A technology for robots and robot bodies, applied in the field of robots, can solve problems such as low efficiency, and achieve the effects of simple structure design, efficient paint removal and rust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

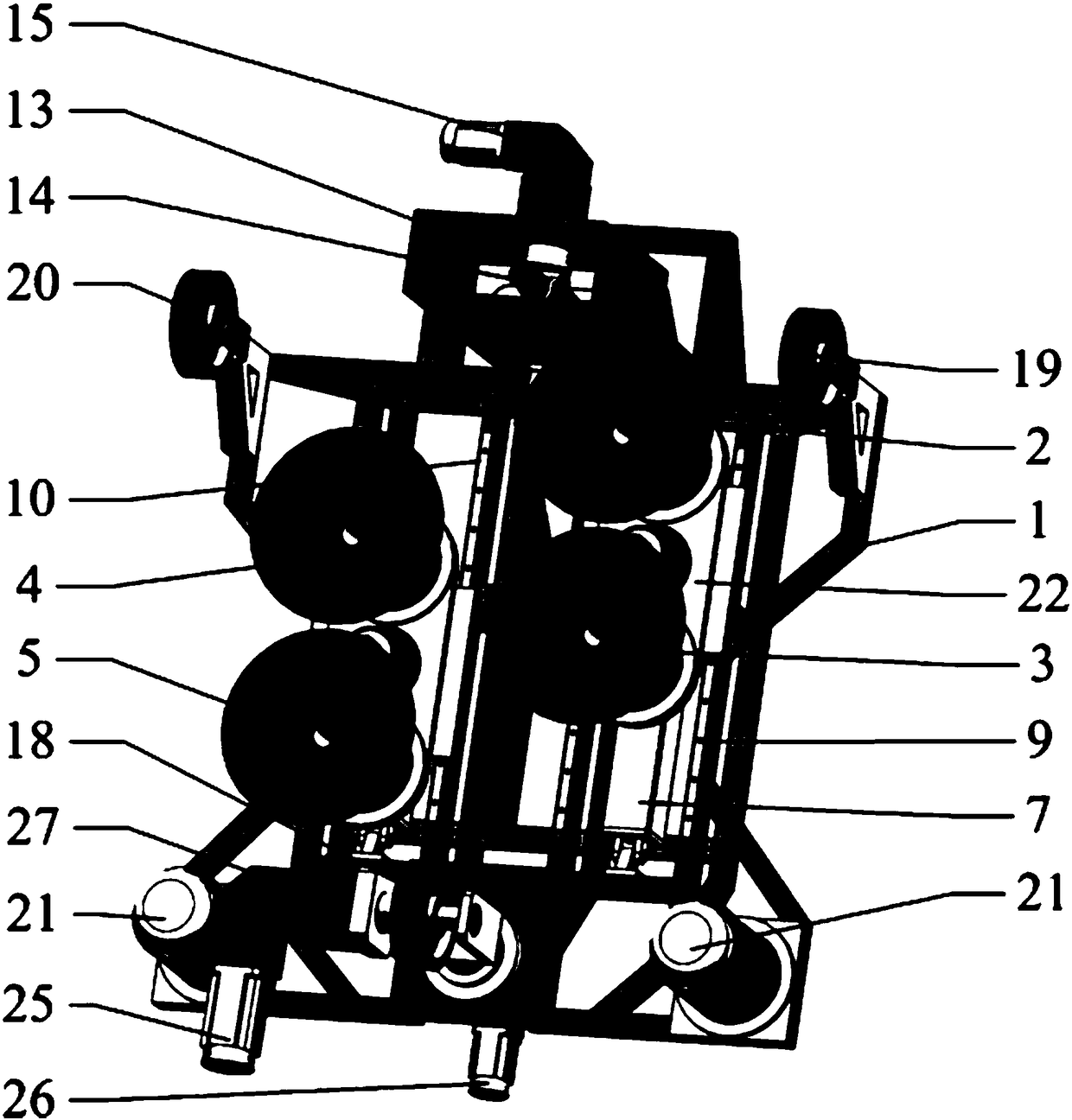

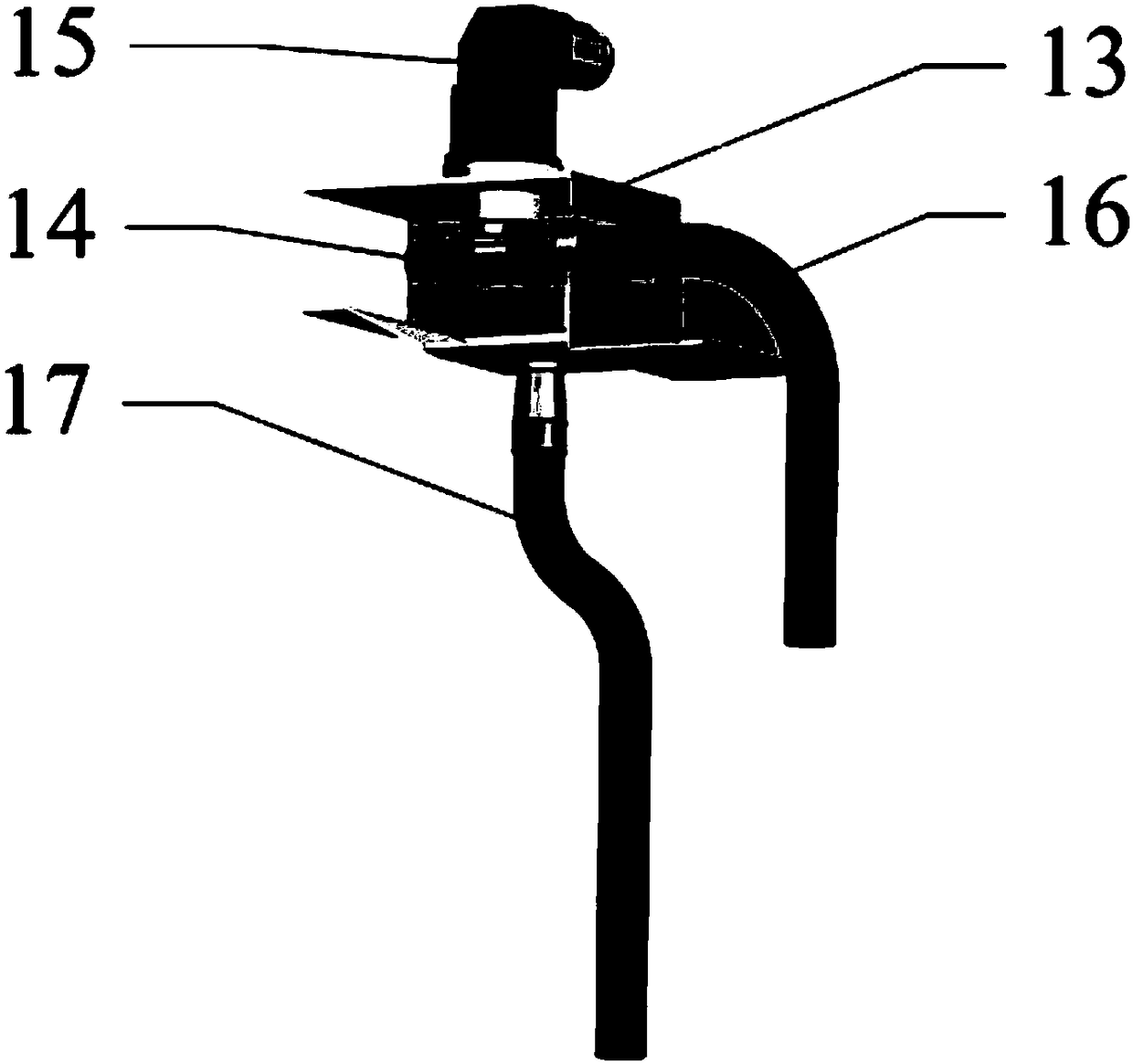

[0053] Embodiment: combine below Figure 1 to Figure 5 This embodiment will be described in detail.

[0054] The wall-climbing type shot-peening robot described in this embodiment comprises a wall-climbing type shot-peening robot body, and the wall-climbing type shot-peening robot body includes a frame 1, a walking mechanism and a shot-peening mechanism;

[0055] The walking mechanism includes a wheeled walking unit and a negative pressure adsorption unit;

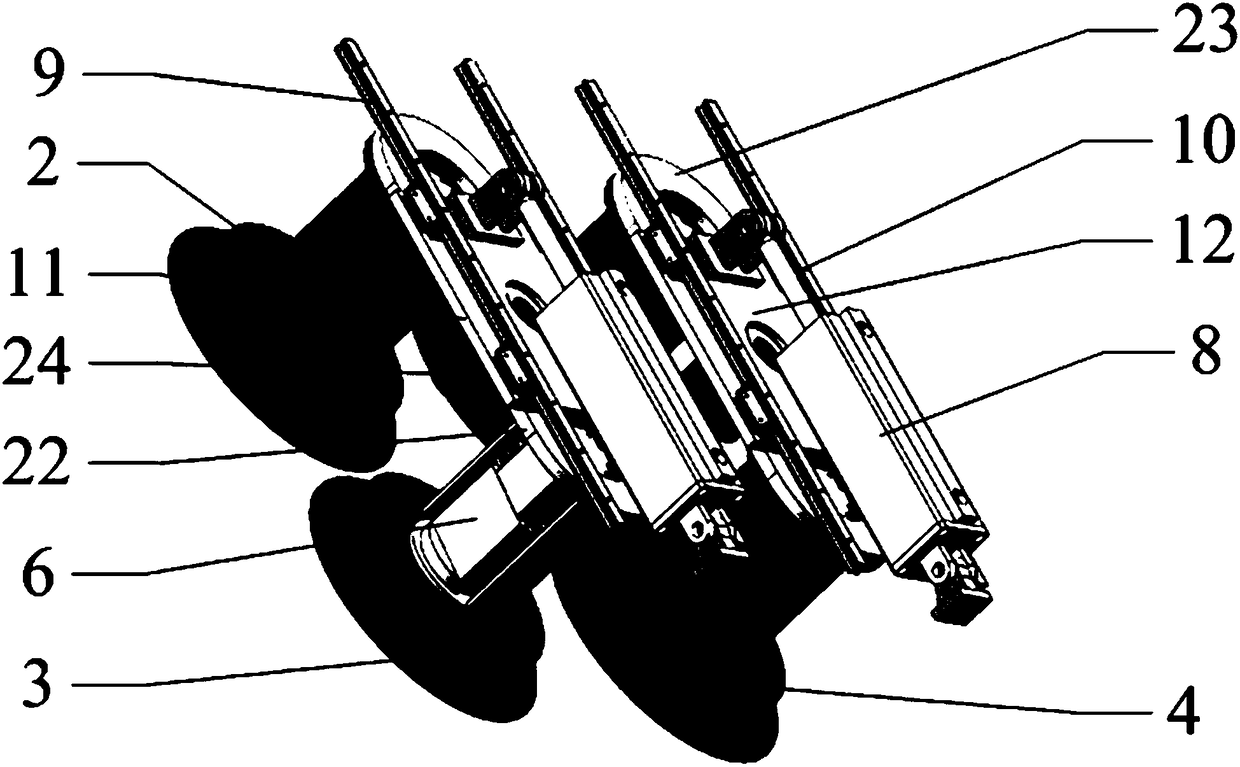

[0056] The negative pressure adsorption unit includes a first vacuum chuck 2, a second vacuum chuck 3, a third vacuum chuck 4, a fourth vacuum chuck 5, a first cylinder, a second cylinder 6, a third cylinder, a fourth cylinder, and a fifth cylinder 7 , the sixth cylinder 8, the first vacuum pump, the first air pump, the first linear guide 9, the second linear guide 10, the first slide 11 and the second slide 12;

[0057]The first linear guide 9 and the second linear guide 10 are arranged side by side on the bottom surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com