Preparation method of titanium alloy three-dimensional lattice heat-resistant structure filled with aerogel

A three-dimensional lattice and titanium alloy technology, applied in chemical instruments and methods, lamination devices, lamination, etc., can solve the problems of high production cost, improved efficiency, lack of mechanical properties and bearing capacity, etc., and achieve low production cost , good mechanical properties and carrying capacity, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Such as Figure 7-9 As shown, a method for preparing a titanium alloy three-dimensional lattice heat-resistant structure filled with airgel, filling the lower half of the internal space of the titanium alloy three-dimensional lattice structure with airgel, and the upper half of the internal space of the titanium alloy three-dimensional lattice structure The part is actively cooled by gas; the closed plasma module 14 is covered outside the titanium alloy three-dimensional lattice structure, and the plasma excitation power supply 5 is placed inside the titanium alloy three-dimensional lattice structure.

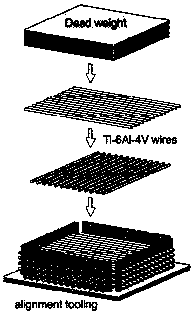

[0049]The method for filling the lower half of the inner space of the three-dimensional lattice structure with aerogel includes that the first step is to process the grid structure of the non-grid core board 8; the second step is to solder flux coating; the third step is to core board Lamination with the panel; the fourth step is the diffusion connection between the core...

Embodiment 2

[0052] Such as Figure 7-9 As shown, a method for preparing a titanium alloy three-dimensional lattice heat-resistant structure filled with airgel, filling the lower half of the internal space of the titanium alloy three-dimensional lattice structure with airgel, and the upper half of the internal space of the titanium alloy three-dimensional lattice structure The part is actively cooled by gas; the closed plasma module 14 is covered outside the titanium alloy three-dimensional lattice structure, and the plasma excitation power supply 5 is placed inside the titanium alloy three-dimensional lattice structure.

[0053] The method for filling the lower half of the inner space of the three-dimensional lattice structure with aerogel includes that the first step is to process the grid structure of the non-grid core board 8; the second step is to solder flux coating; the third step is to core board Lamination with the panel; the fourth step is the diffusion connection between the cor...

Embodiment 3

[0061] Such as Figure 7-9 As shown, a method for preparing a titanium alloy three-dimensional lattice heat-resistant structure filled with airgel, filling the lower half of the internal space of the titanium alloy three-dimensional lattice structure with airgel, and the upper half of the internal space of the titanium alloy three-dimensional lattice structure The part is actively cooled by gas; the closed plasma module 14 is covered outside the titanium alloy three-dimensional lattice structure, and the plasma excitation power supply 5 is placed inside the titanium alloy three-dimensional lattice structure.

[0062] The method for filling the lower half of the inner space of the three-dimensional lattice structure with aerogel includes that the first step is to process the grid structure of the non-grid core board 8; the second step is to solder flux coating; the third step is to core board Lamination with the panel; the fourth step is the diffusion connection between the cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com