Method for preparing gold-copper alloy nano particles

A nanoparticle, gold-copper alloy technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

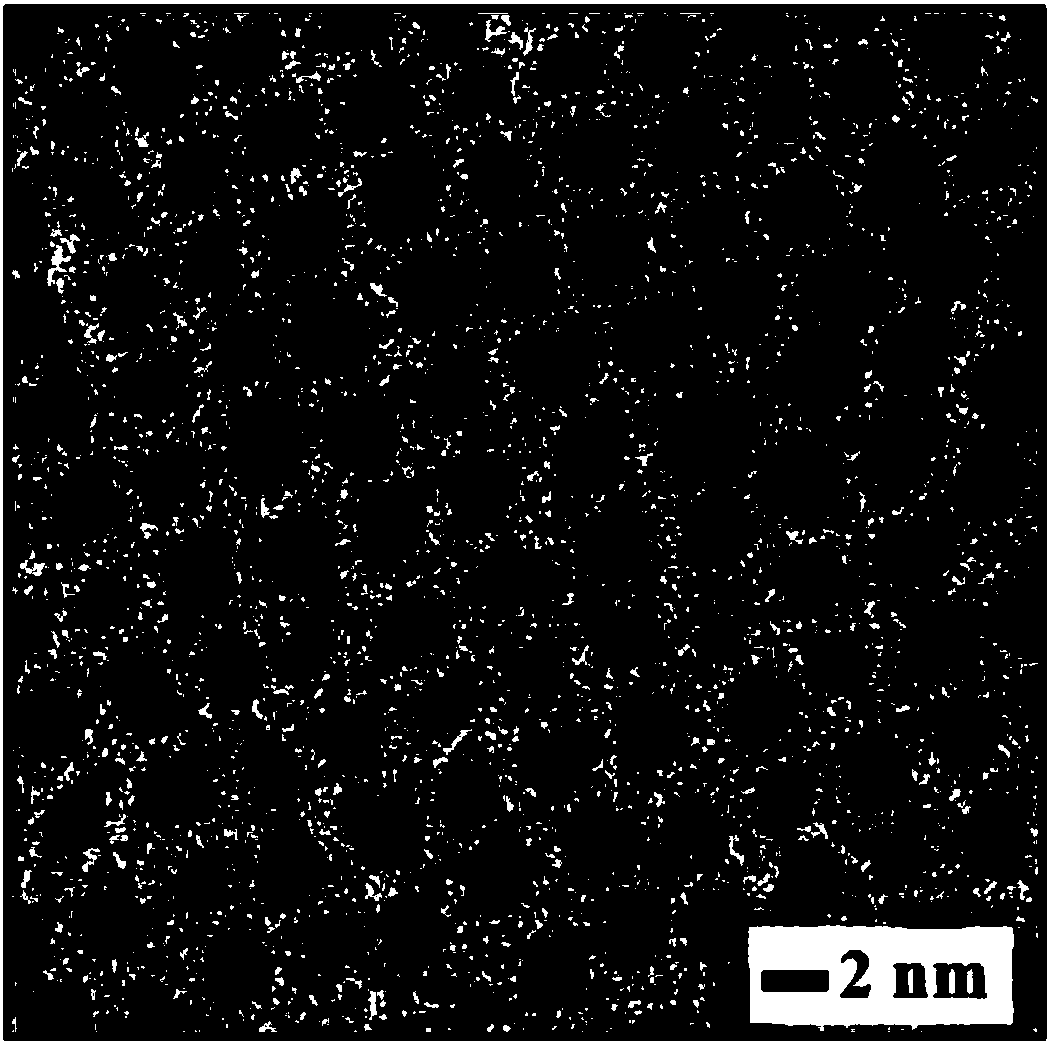

[0024] Preparation and characterization of gold-copper alloy nanoparticles (~2 nm):

[0025] (1) Preparation of copper precursor solution and gold precursor solution

[0026] The cupric chloride that buys is mixed with deionized water 40 milliliters of the copper precursor solution of 0.06 mol / liter, and adds appropriate tetrachloroauric acid, obtains cupric chloride: tetrachloroauric acid mol ratio is the mixed solution of 1:1, Stir well. In addition, sodium borohydride was prepared into a 2.4 mol / liter reducing agent solution with deionized water.

[0027] (2) Phase transfer process

[0028] Add 80 ml of toluene to the above mixed solution, and add a sufficient amount of 0.7 g of tetraoctyl ammonium bromide to form an organic phase, stir for 40 minutes, transfer the copper particles and chloroauric acid to the organic phase, and form a deep red orange . Separate again through a separatory funnel to remove the aqueous layer. The remaining organic mixed solution was trans...

Embodiment 2

[0034] Preparation and characterization of gold-copper alloy nanoparticles (~5 nm):

[0035] (1) Preparation of copper precursor solution and gold precursor solution

[0036] The cupric chloride that buys is mixed with deionized water 52 milliliters of the copper precursor solution of 0.04 mol / liter, and adds appropriate tetrachloroauric acid, obtains cupric chloride: tetrachloroauric acid mol ratio is the mixed solution of 1:1, Stir well. In addition, sodium borohydride was prepared with deionized water to form a 2.0 mol / liter reducing agent solution.

[0037] (2) Phase transfer process

[0038] Add 80 ml of toluene to the above mixed solution, and add a sufficient amount of 0.7 g of tetraoctyl ammonium bromide to form an organic phase, stir for 40 minutes, transfer the copper particles and chloroauric acid to the organic phase, and form a deep red orange . Separate again through a separatory funnel to remove the aqueous layer. The remaining organic mixed solution was tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com