Casting method of billet continuous casting machine tundish using sizing nozzle in steelmaking enterprises

A small billet continuous casting and sizing nozzle technology, applied in the field of steelmaking, can solve the problems of inability to precisely control the size of the injection flow, easy accumulation around the mold, affecting the billet drawing speed, etc., to improve work stability and operation. efficiency, reducing the cost of refractory materials and equipment spare parts, and reducing the labor intensity of employees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

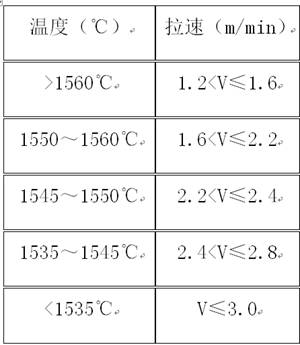

[0026] A method for casting a tundish of a billet continuous casting machine in a steelmaking enterprise using a sizing nozzle, comprising the following steps:

[0027] 1. Requirements for the temperature of molten steel when sizing and starting:

[0028] HRB series steel:

[0029] (1) The liquidus line of molten steel is 1510°C, and the superheat is ≤35°C.

[0030] (2) Requirements for molten steel temperature:

[0031] Start the first furnace and insert climbing: 1610 ℃ ~ 1630 ℃,

[0032] In normal casting state: (1575°C ~ 1590°C).

[0033] Tundish temperature control range: starting pouring is greater than 1570°C, normal control is ≤1545°C.

[0034] Optimum temperature control range for tundish: 1530°C to 1545°C.

[0035] HPB series steel:

[0036] (1) Liquidus line of molten steel is 1515°C, superheat ≤35°C

[0037] (2) Requirements for molten steel temperature:

[0038] Start the first furnace and insert climbing: 1605℃~1625℃

[0039] Under normal casting conditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com