Lower mould base mechanism capable of automatically collecting materials

A technology of automatic material receiving and lower die base, applied in metal processing equipment, feeding devices, forming tools, etc., can solve the problems of reducing production efficiency, time-consuming and laborious, inconvenient production operation, etc., to improve efficiency and avoid manual collection. , saving time and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

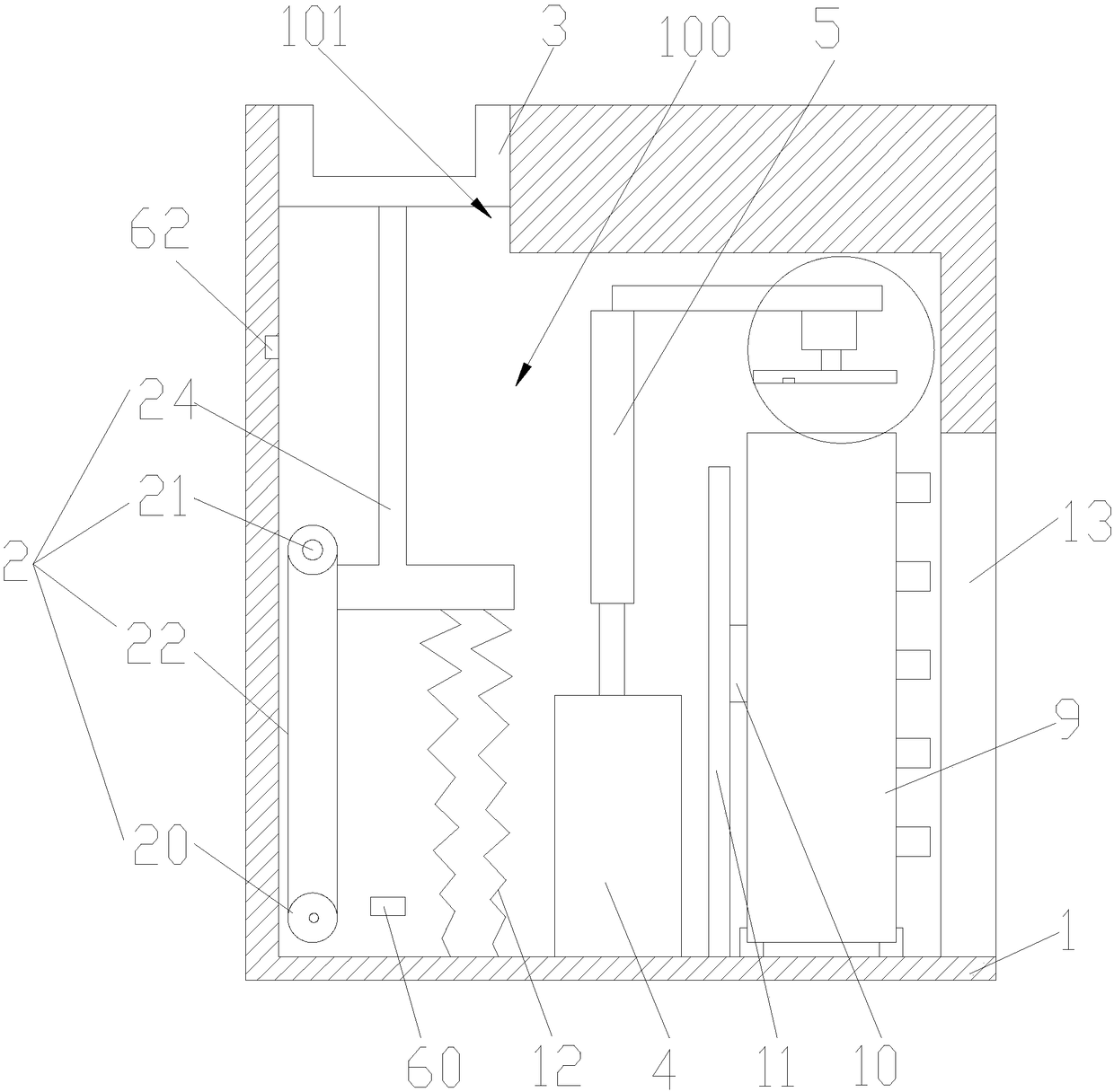

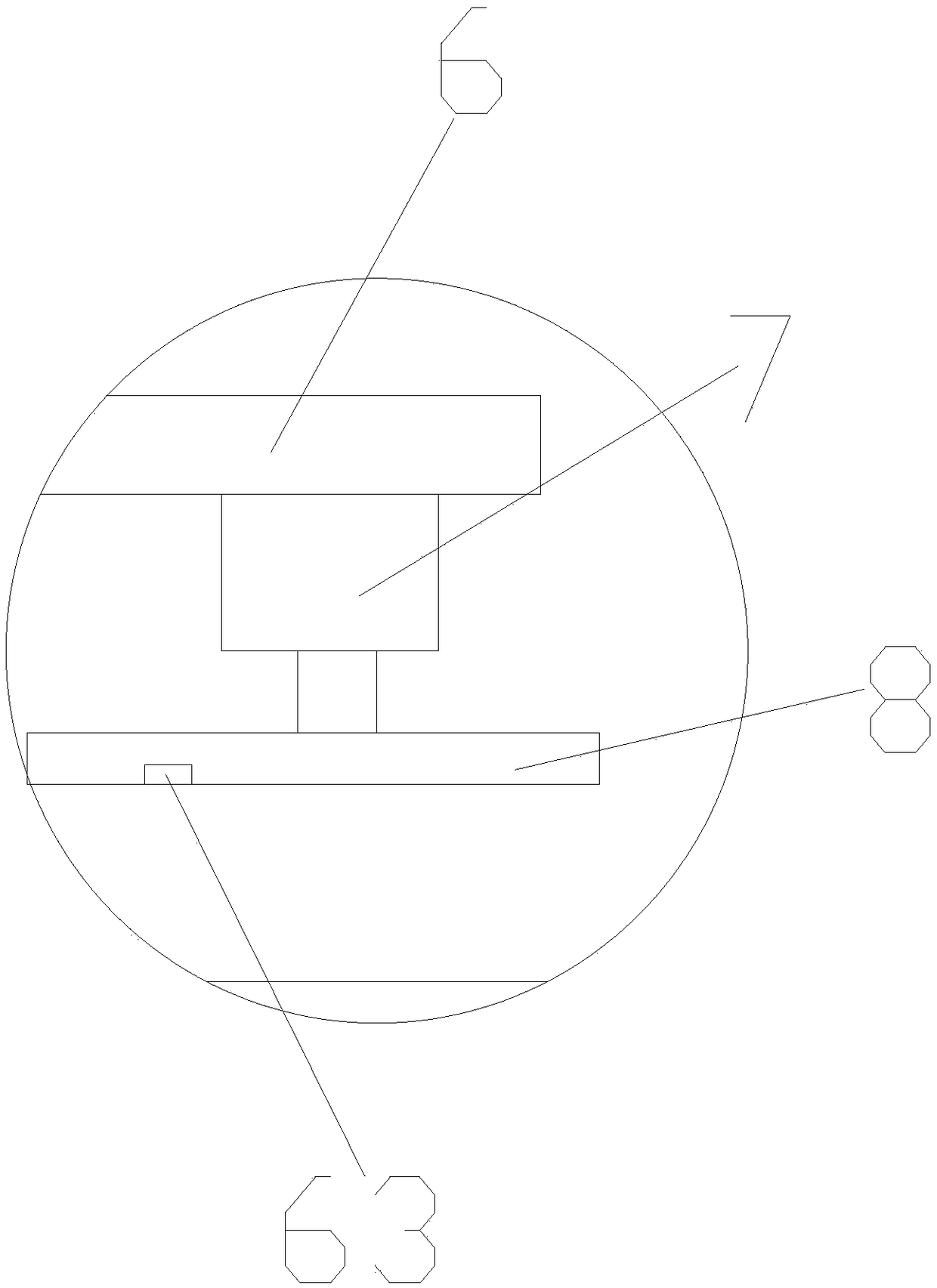

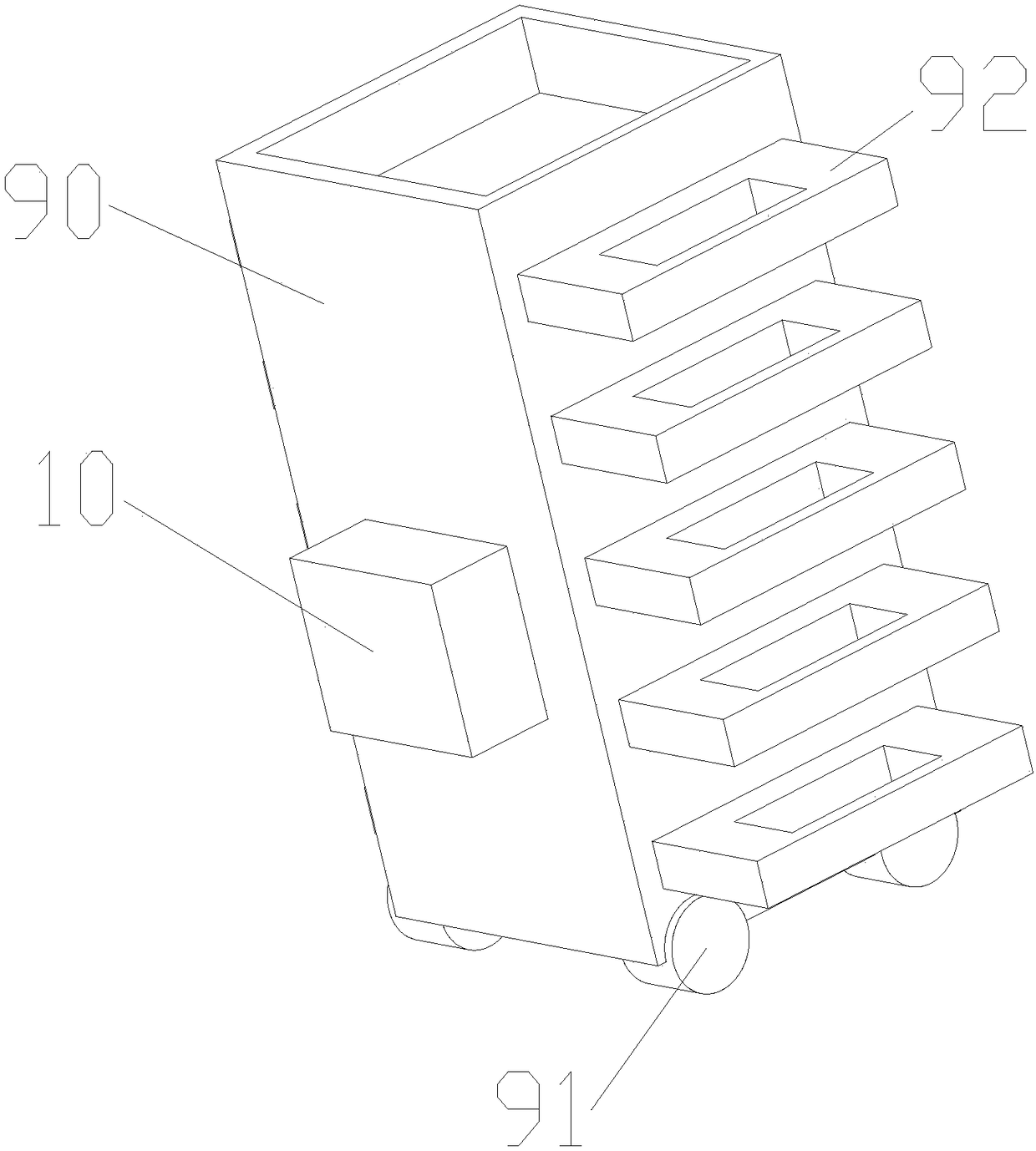

[0016] as attached Figure 1-3 The shown lower mold base mechanism of the present invention that can automatically collect materials includes a base 1, a drive mechanism 2 located in the accommodation cavity 100 of the base 1, a lower mold base 3, a rotating motor 4, a rotating shaft 5, Swivel frame 6, telescopic rod 7, suction cup 8, material storage mechanism 9, electromagnet 10 and iron plate 11; The upper end of the base 1 is provided with a through hole 101 communicating with the accommodating cavity 100; The through hole 101 is provided with The lower mold base 3 that can move up and down through the driving mechanism 2, the above-mentioned driving mechanism 2 is arranged in the base 1; the upper end of the lower mold base 3 has a die; Motor 4; the upper end of the rotating motor 4 is connected to the rotatable rotating frame 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com