A construction waste crushing device

A technology of crushing device and construction waste, applied in the direction of grain processing, etc., can solve the problems of increasing the workload of staff, large gap between construction waste, and increasing labor costs, and achieve the effect of reducing workload, reducing labor costs, and reducing maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

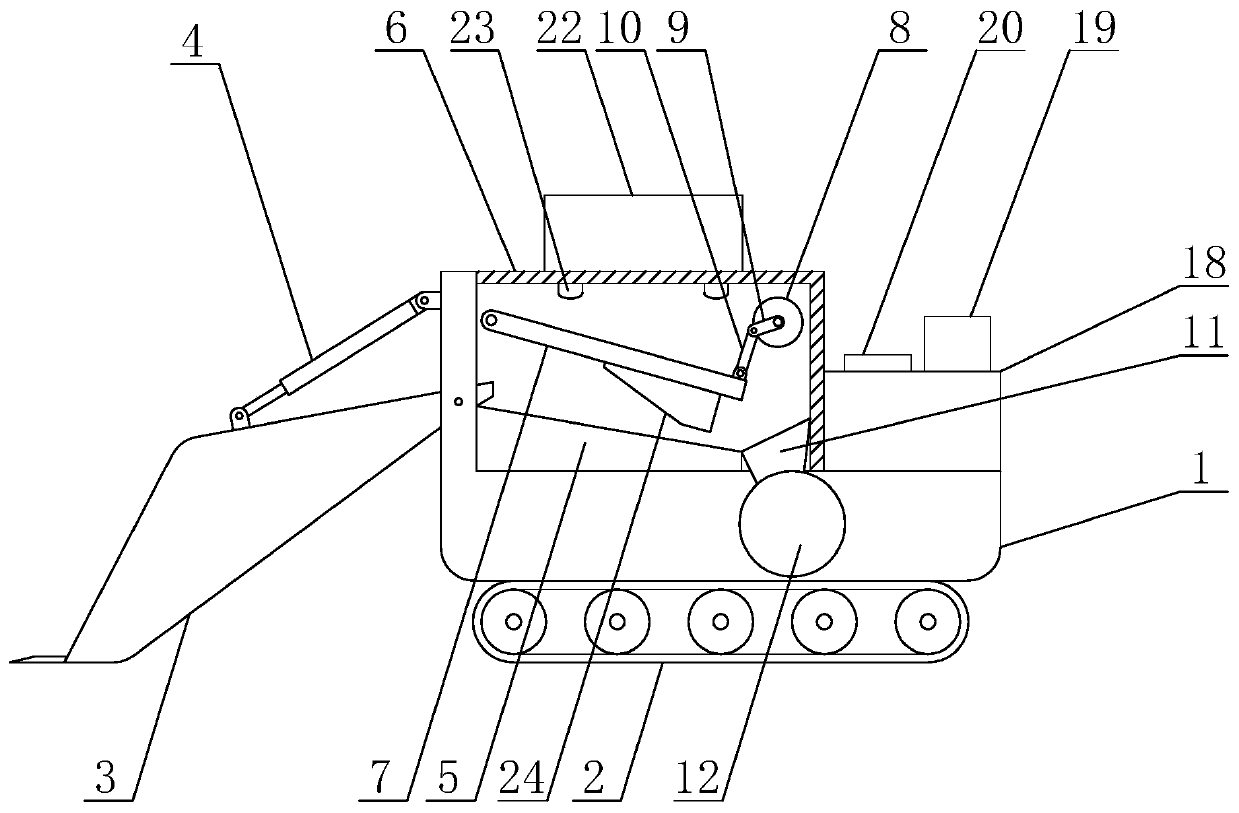

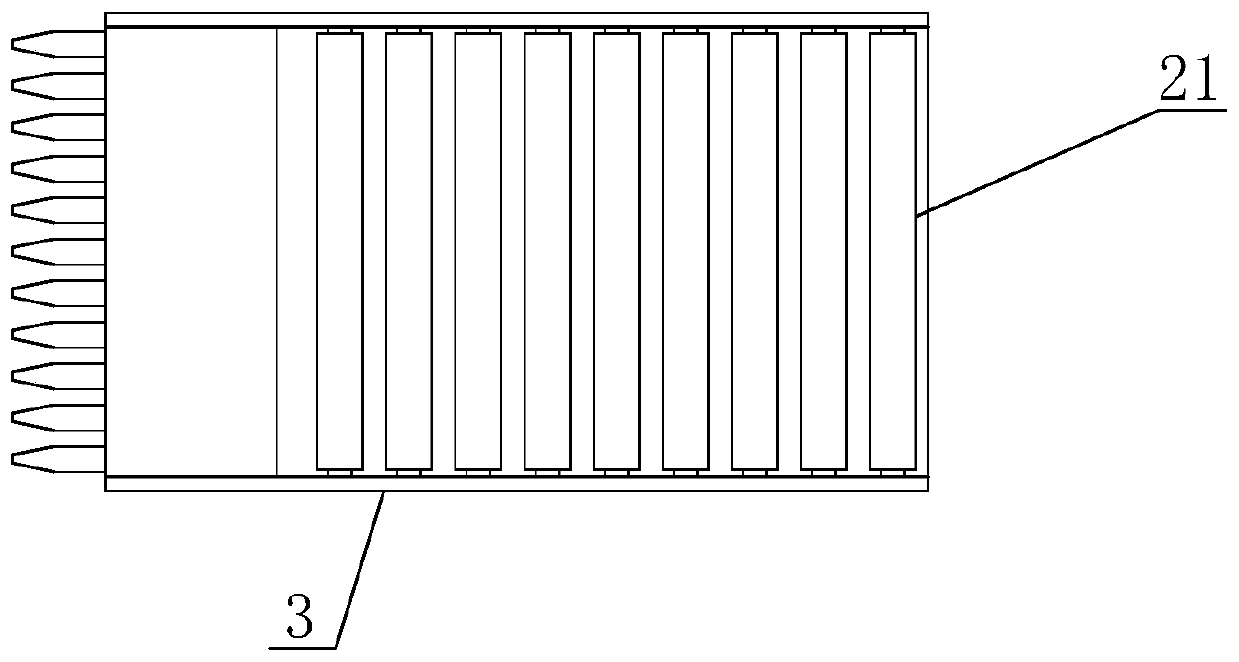

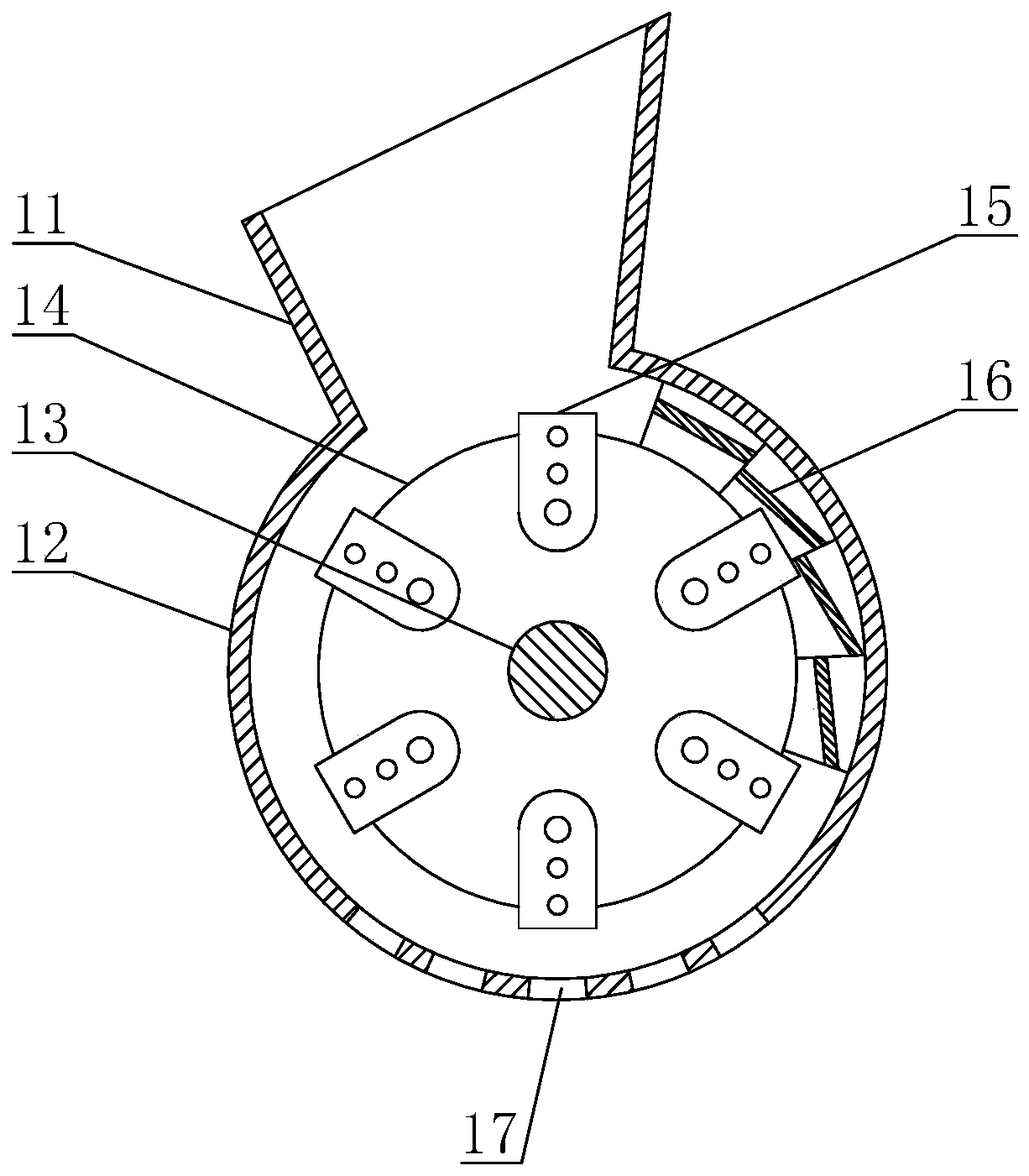

[0023]Embodiment: The present invention is a construction waste crushing device, which includes a frame 1, and a crawler drive mechanism 2 is installed on the bottom of the frame 1, and the crawler drive mechanism 2 drives the present invention to move. One end of the frame 1 is provided with a feeding bucket 3, and several rollers 21 are installed on the bottom of the feeding bucket 3, which can reduce the friction between construction waste and the feeding bucket 3, and reduce the impact on the feeding material. The wear of the bucket 3 reduces the maintenance cost of the present invention. The bottom of one end of the feed bucket 3 close to the frame 1 is hinged with the frame 1, the upper side of the feed bucket 3 is provided with an adjustment cylinder 4, and one end of the adjustment cylinder 4 is hinged with the frame 1, The other end is hinged with the feeding bucket 3, and the height of the front end of the feeding bucket 3 can be adjusted as required. The side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com