A double-chamber cupping device

A technology of double air chambers and tanks, applied in the field of medical devices, can solve the problems of increasing patient pain, poor effect, skin damage, etc., and achieve the effect of avoiding pain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

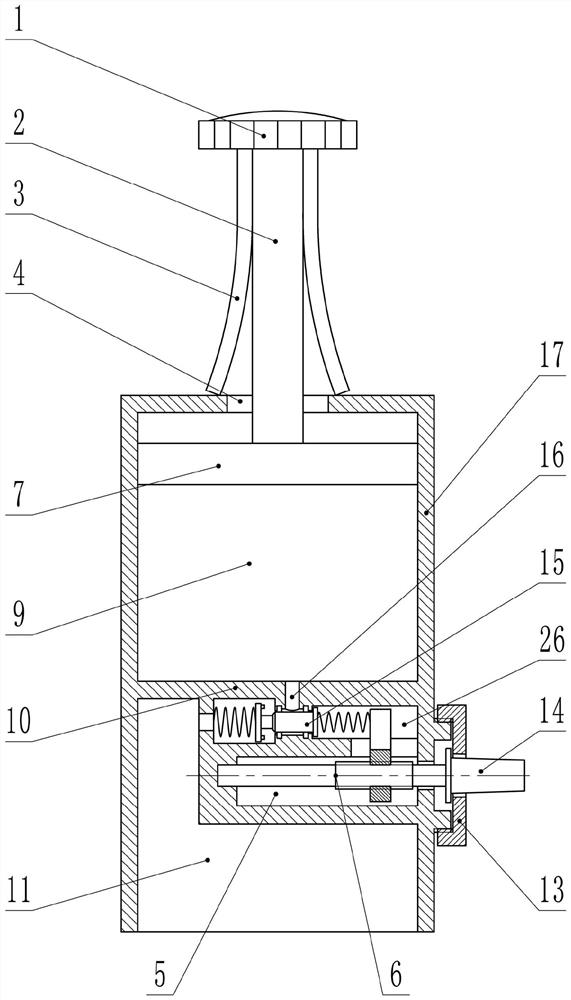

[0017] In embodiment 1, such as figure 1 , 2 As shown, the present invention includes a cylindrical tank body 17 with an open lower end, and the tank body 17 is provided with a partition 10 and a piston 7 . The partition 10 is fixed in the middle of the tank body 17 , and divides the inside of the tank body 17 into upper and lower cavities, namely an upper cavity 9 and a lower cavity 11 . The piston 7 is located in the upper cavity 9, the periphery of the piston 7 is airtightly connected to the inner surface of the tank body 17, the upper surface of the piston 7 is fixedly connected to the piston rod 2, and the upper wall of the tank body 17 is provided with a piston port 4, The piston rod 2 protrudes from the piston port 4, and the upper end of the piston rod 2 is fixedly connected to the piston handle 1. Pushing the piston 7 up and down by the piston handle 1 can change the air pressure in the cavity of the tank body 17 .

[0018] Such as figure 1 As shown, one or more s...

Embodiment 2

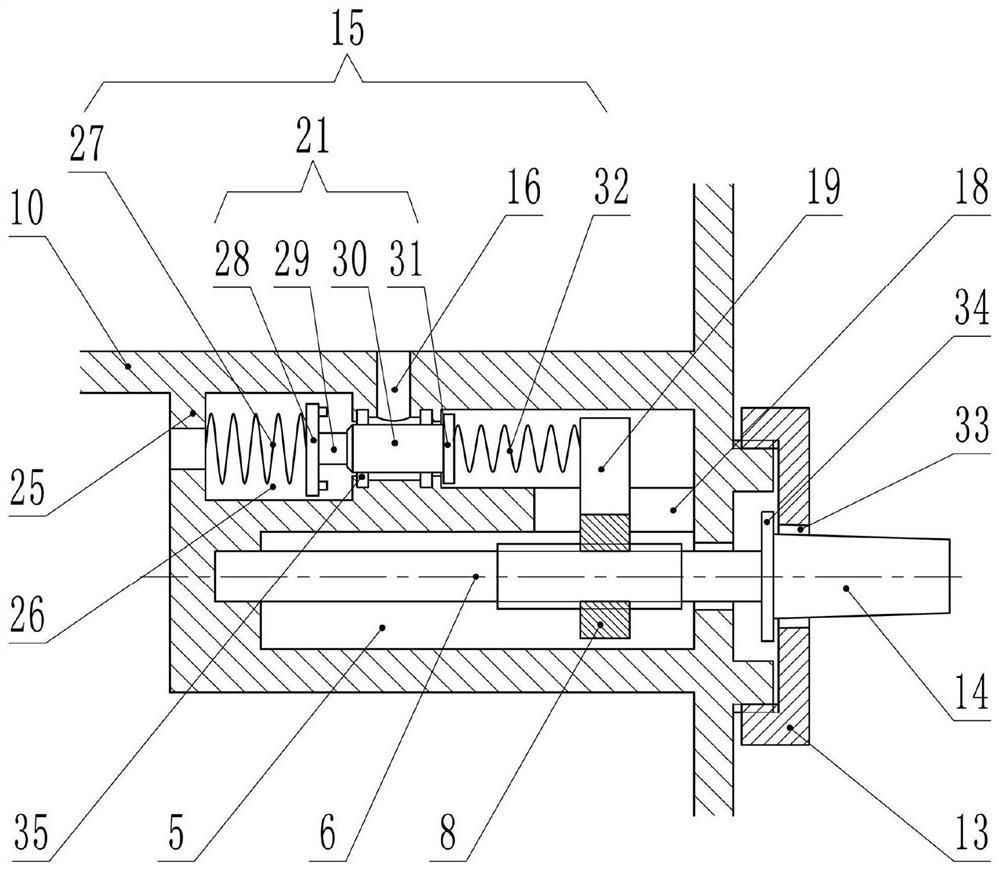

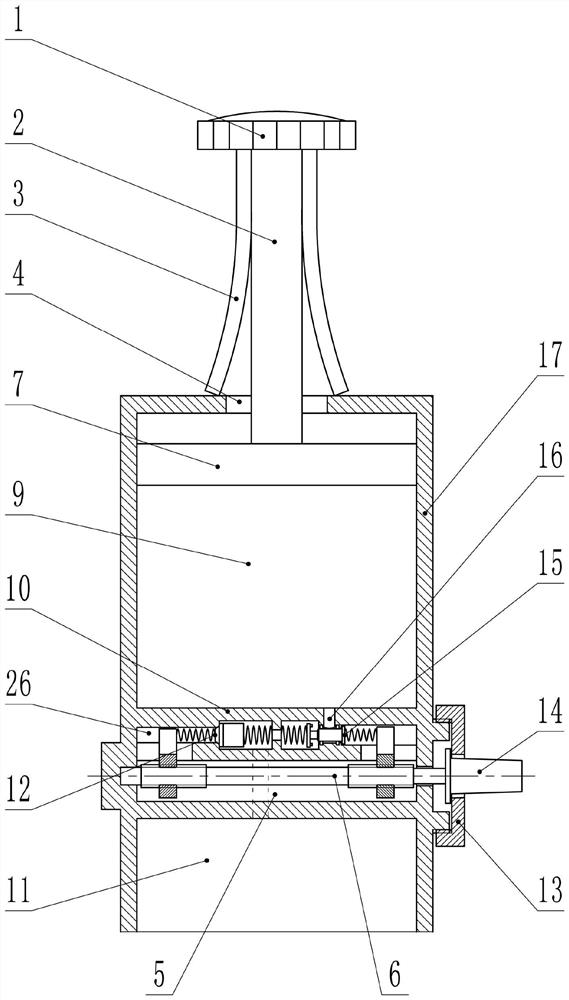

[0028] In embodiment 2, such as image 3 , 4 As shown, in addition to the technical features in Embodiment 1, this embodiment also includes an intake valve 12 . In this embodiment, except for the technical features related to the intake valve 12, other technical features are the same as those in Embodiment 1, and will not be repeated in this embodiment.

[0029] The intake valve 12 is located in the No. 2 hole 26. In this embodiment, the inner flange 25 is located in the middle of the No. 2 hole 26, and the structure in front of the inner flange 25 is the outlet valve 15. Its structure Same as Embodiment 1, the structure behind the inner flange 25 is the intake valve 12 . The intake valve 12 communicates with the outside of the lower chamber 11 and the tank body 17, and its function is to allow external air to enter the lower chamber 11 to increase the air pressure in the lower chamber 11.

[0030] Two strip-shaped holes 18 are respectively arranged between the front and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com