Sterilization control system and sterilization control method for cookware and the cookware

A technology of cooking utensils and control systems, which is applied in the field of sterilization control systems, can solve problems such as inability to sterilize, and achieve the effects of preventing food deterioration, humidity, and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

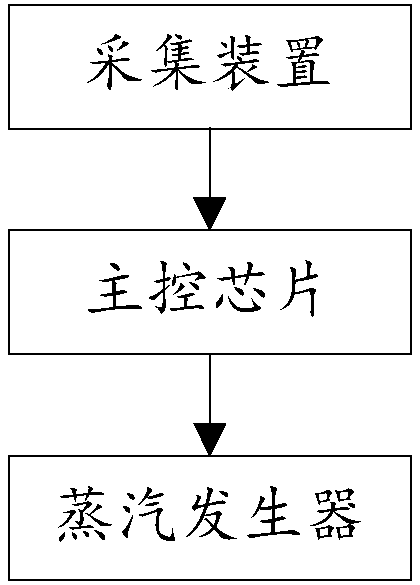

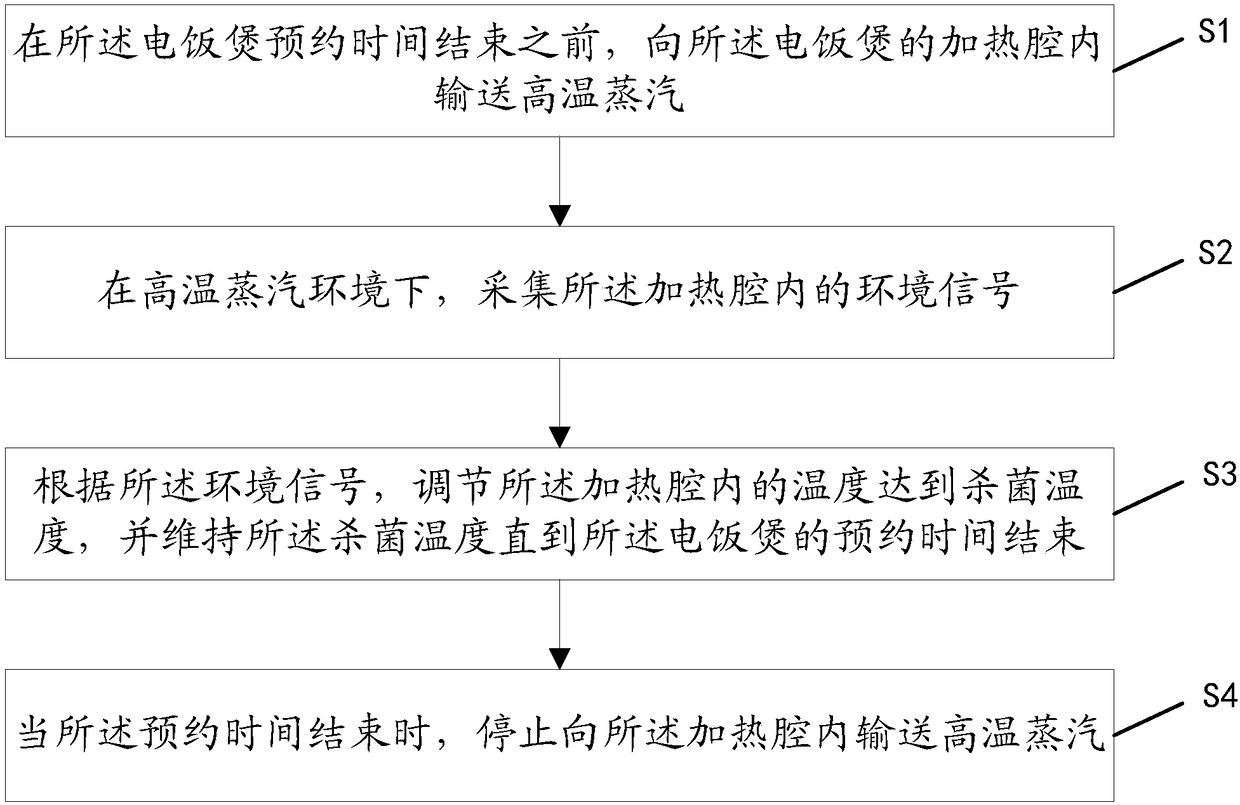

[0058] like figure 1 As shown, a sterilization control system for a cooking utensil in this embodiment includes a main control chip 4, a collection device 5 and a steam generator 3, and the steam generator 3 communicates with the heating cavity 21 of the cooking utensil;

[0059] The main control chip 4 is used to send a start command to the steam generator 3 at the first preset time before the end of the cooking utensil reservation or the first preset time before the end of the heat preservation; when the cooking utensil reservation ends Or when the heat preservation is over, send a stop instruction to the steam generator 3;

[0060] The steam generator 3 is used to start delivering high-temperature steam into the heating cavity 21 of the cooking appliance to adjust the temperature of the heating cavity 21 when the start instruction is received; when the stop instruction is received , no longer running;

[0061] The collection device 5 is used to collect the environmental s...

Embodiment approach 1

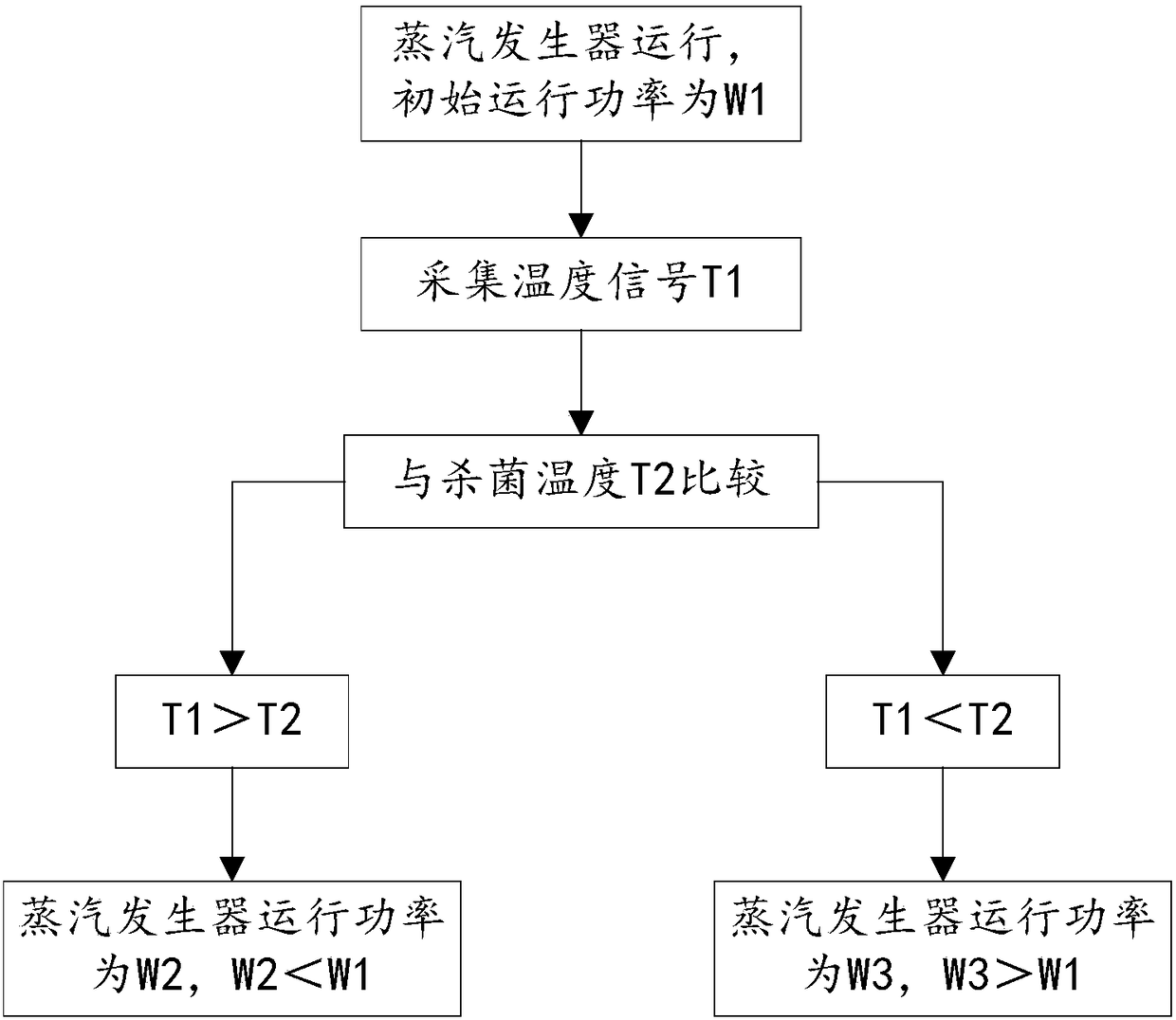

[0067] Embodiment 1, such as figure 1 and Figure 4 The environmental signal in this embodiment is a temperature signal; when the environmental signal is a temperature signal, the collection device 5 is a temperature collector, and the temperature collector is used to collect the temperature signal in the heating chamber 21 and then The temperature signal is sent to the main control chip 4;

[0068] The main control chip 4 is used to reduce the average power of the steam generator 3 when the temperature value corresponding to the temperature signal is higher than the sterilization temperature, so that the temperature in the heating chamber 21 is maintained at the sterilization temperature. Temperature; when the temperature signal is lower than the sterilization temperature, the average power of the steam generator 3 is increased to maintain the temperature in the heating chamber 21 at the sterilization temperature. By feeding back the temperature to the main control chip 4 t...

Embodiment approach 2

[0069] Embodiment 2: In this embodiment, the start and stop of the steam generator 3 is mainly controlled by temperature. In addition to directly using a temperature collector to collect temperature, indirect temperature measurement can also be used. Since there is a one-to-one correspondence between temperature and pressure in the saturated state of steam, the temperature can be limited by limiting the pressure.

[0070] The environmental signal in this embodiment is a pressure signal; when the environmental signal is a pressure signal, the collecting device 5 is a pressure collecting device, and the pressure collecting device is used when the water vapor in the heating chamber 21 reaches saturation At the time of collection, the pressure signal in the heating chamber 21 is collected and the pressure signal is sent to the main control chip 4;

[0071] The main control chip 4 is used to reduce the average power of the steam generator 3 when the temperature value corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com