Graphite layer evenly-brushing device for high-voltage cable

A high-voltage cable, graphite layer technology, used in cable/conductor manufacturing, circuits, electrical components, etc., can solve problems such as uneven graphite layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below by means of specific embodiments:

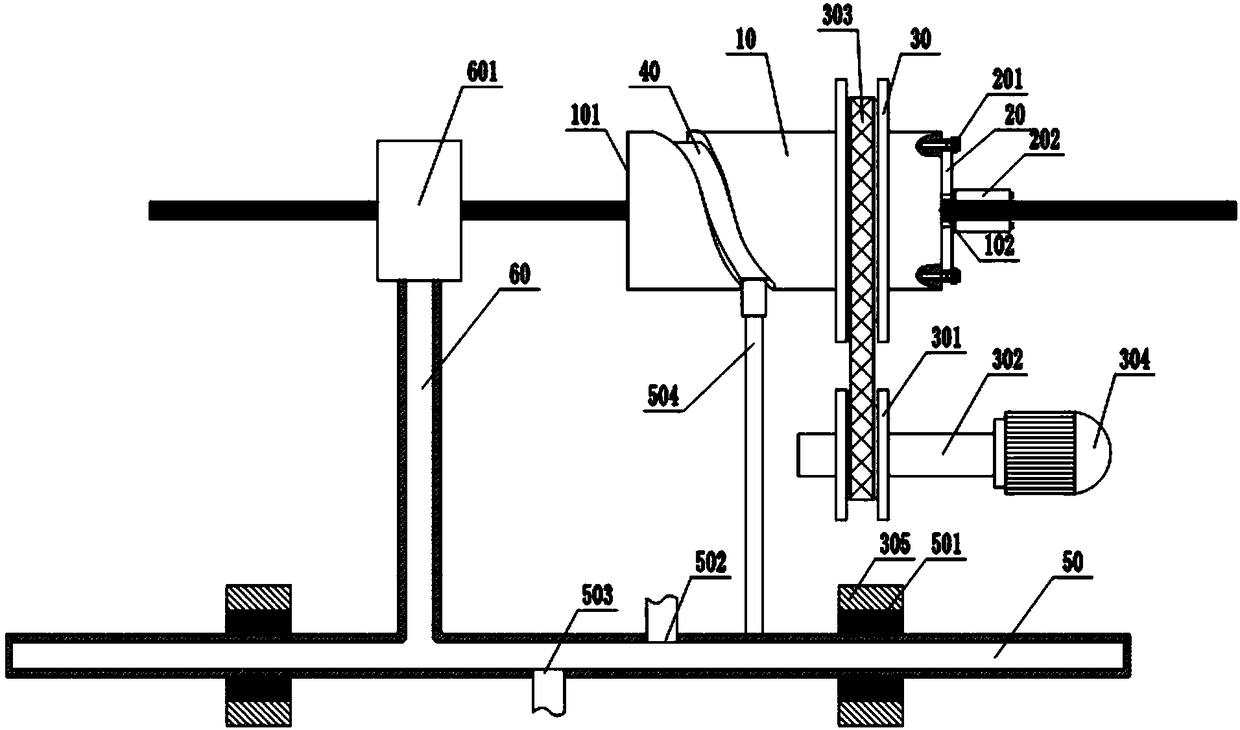

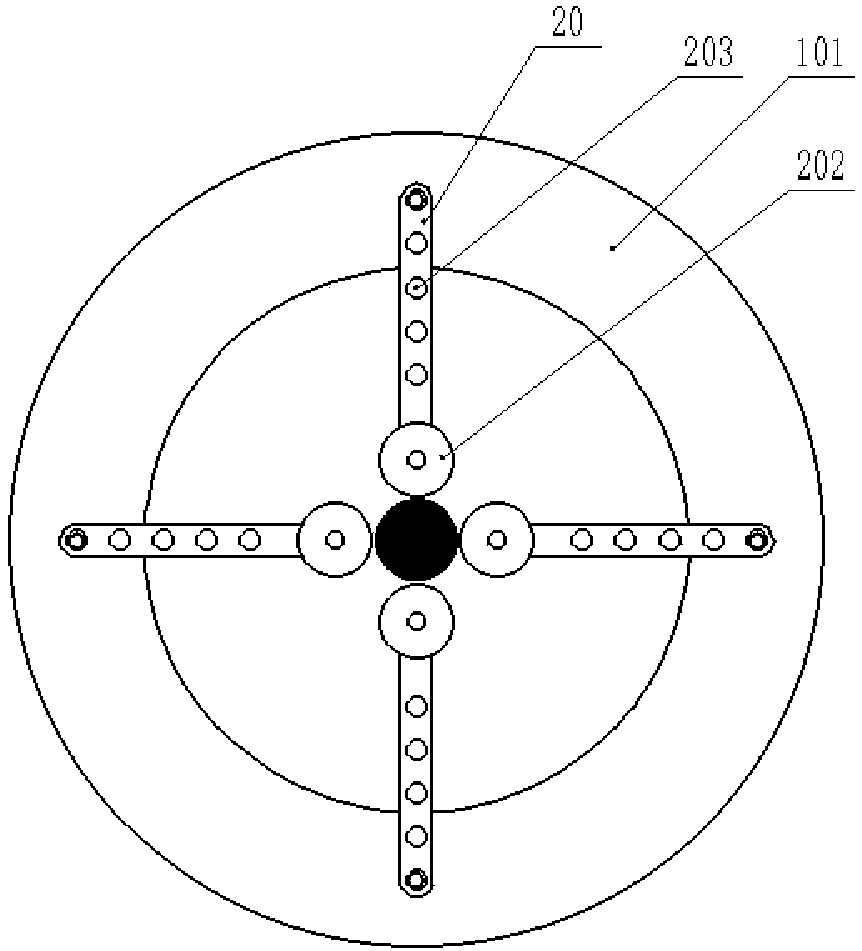

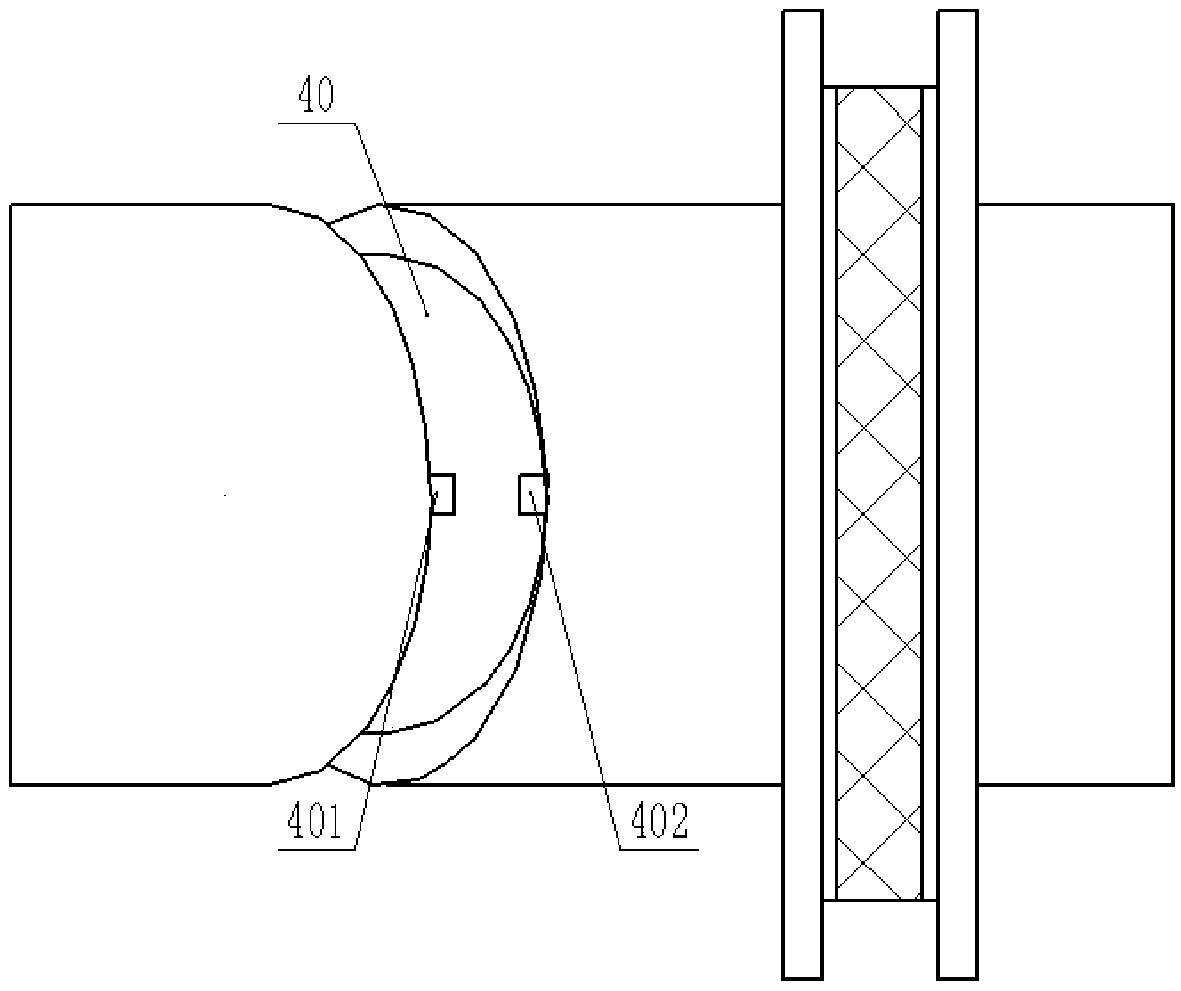

[0028] The reference signs in the drawings of the description include: drum 10, wire inlet end 101, wire outlet end 102, pole 20, bolt 201, roller brush 202, threaded hole 203, driven wheel 30, driving wheel 301, rotating shaft 302, belt 303, motor 304, frame 305, curved groove 40, first normally open contact 401, second normally open contact 402, air pump 403, third normally open contact 404, fourth normally open contact 405, Blowing pump 406, power supply 407, switch 408, air duct 50, spline 501, air inlet 502, exhaust port 503, ejector rod 504, first conductive block 505, second conductive block 506, drawbar 60, mounting plate 601, the outer wall of the disc 602, the inner wall of the disc 603, and the suction cup 604.

[0029] Such as figure 1 As shown, the present invention discloses a high-voltage cable graphite layer brushing device, which includes a rotating cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com