Pixel array substrate

A pixel array substrate and pixel electrode technology, which is applied in the field of array substrates, can solve problems such as display panel bubbles, display panel defects, and color filter patterns that are easy to form sunken areas, and achieve the effect of reducing the probability of bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

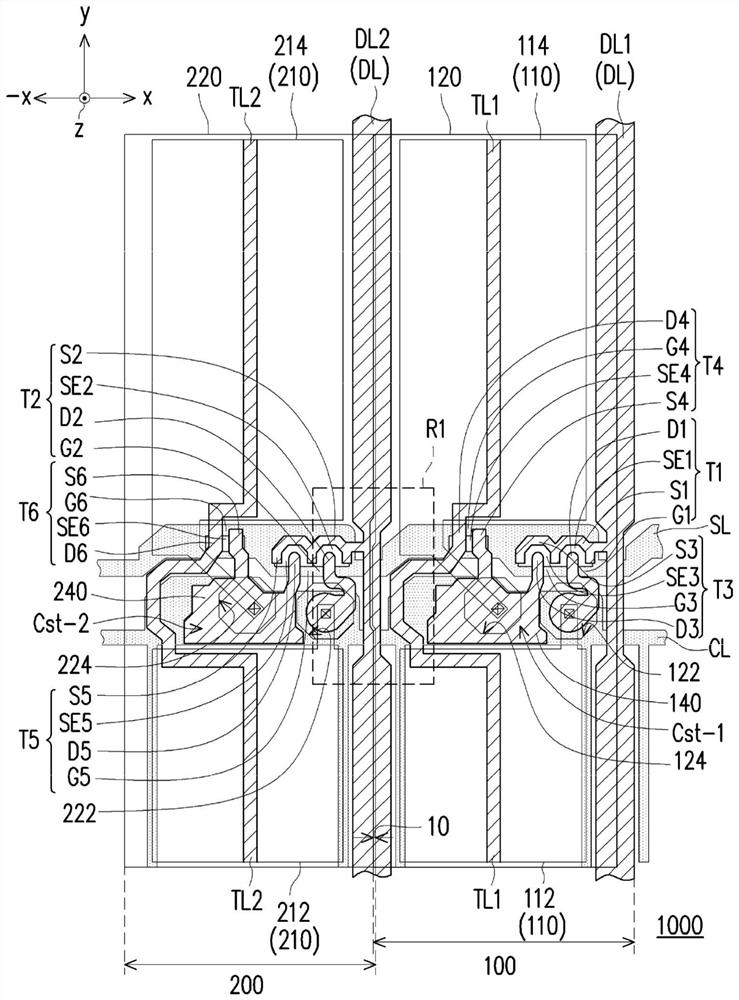

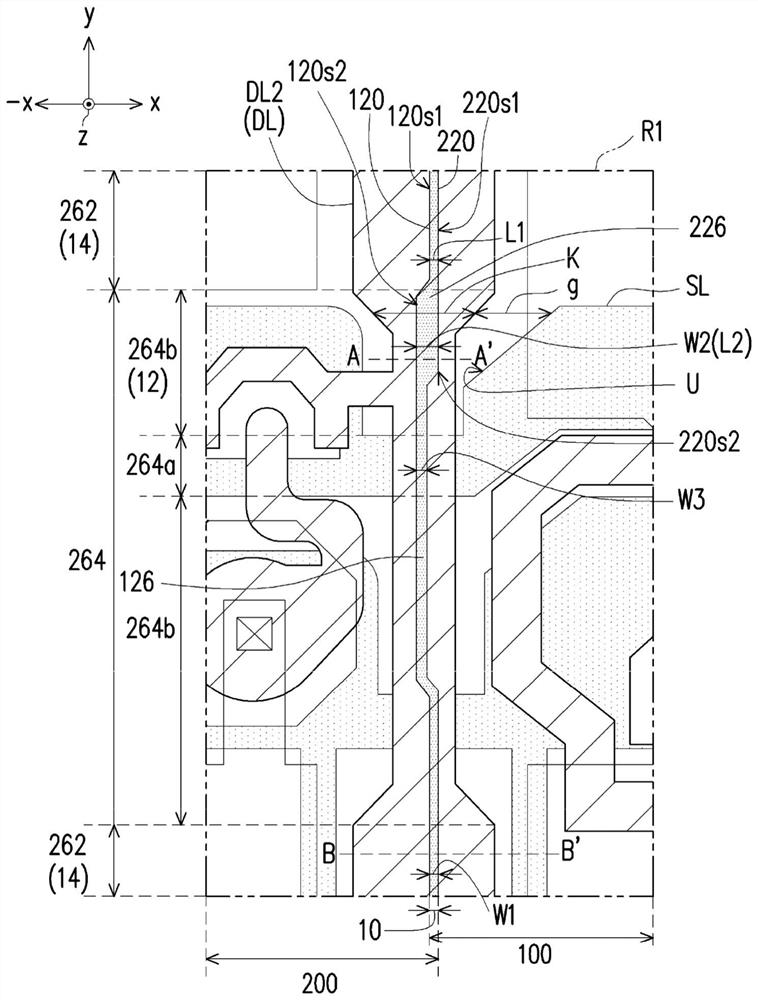

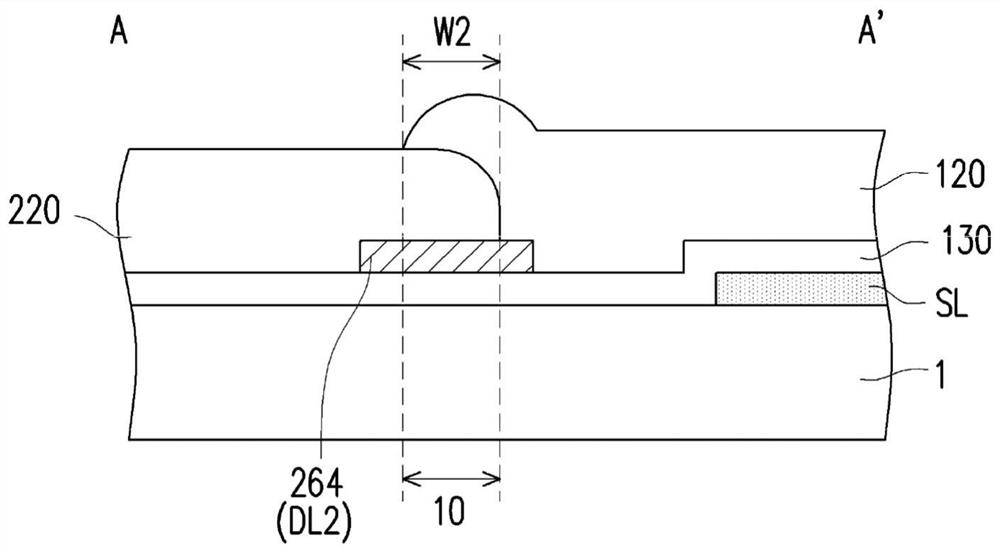

[0069] figure 1 It is a top view of a pixel array substrate according to an embodiment of the present invention. figure 2 for figure 1 The enlarged schematic diagram of the partial R1 of the pixel array substrate. image 3 based on figure 2 The schematic cross-sectional view of the pixel array substrate drawn by the section line A-A'. Figure 4 based on figure 2 The schematic cross-sectional view of the pixel array substrate drawn by the section line B-B'.

[0070] Please refer to figure 1 , figure 2 , image 3 and Figure 4 , the pixel array substrate 1000 includes a substrate 1 (drawn in image 3 and Figure 4 ) and a plurality of first pixel units 100 , a plurality of second pixel units 200 , a plurality of scan lines SL and a plurality of data lines DL disposed on the substrate 1 . The data lines DL and the scan lines SL are arranged alternately. figure 1 Draw a first pixel unit 100, a second pixel unit 200, a scan line SL and two data lines DL1, DL2 as an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com