Fault testing device of power generator stator core and testing method of testing device

A generator stator and fault testing technology, applied in motor generator testing and other directions, can solve the problem that the hand-held coil has a high degree of control over the stability time, the surface of the iron core stator iron core teeth is uneven, and the fault point cannot be accurately judged. and other problems, to achieve the effect of convenient and fast adjustment, high support stability, and convenient and fast traction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

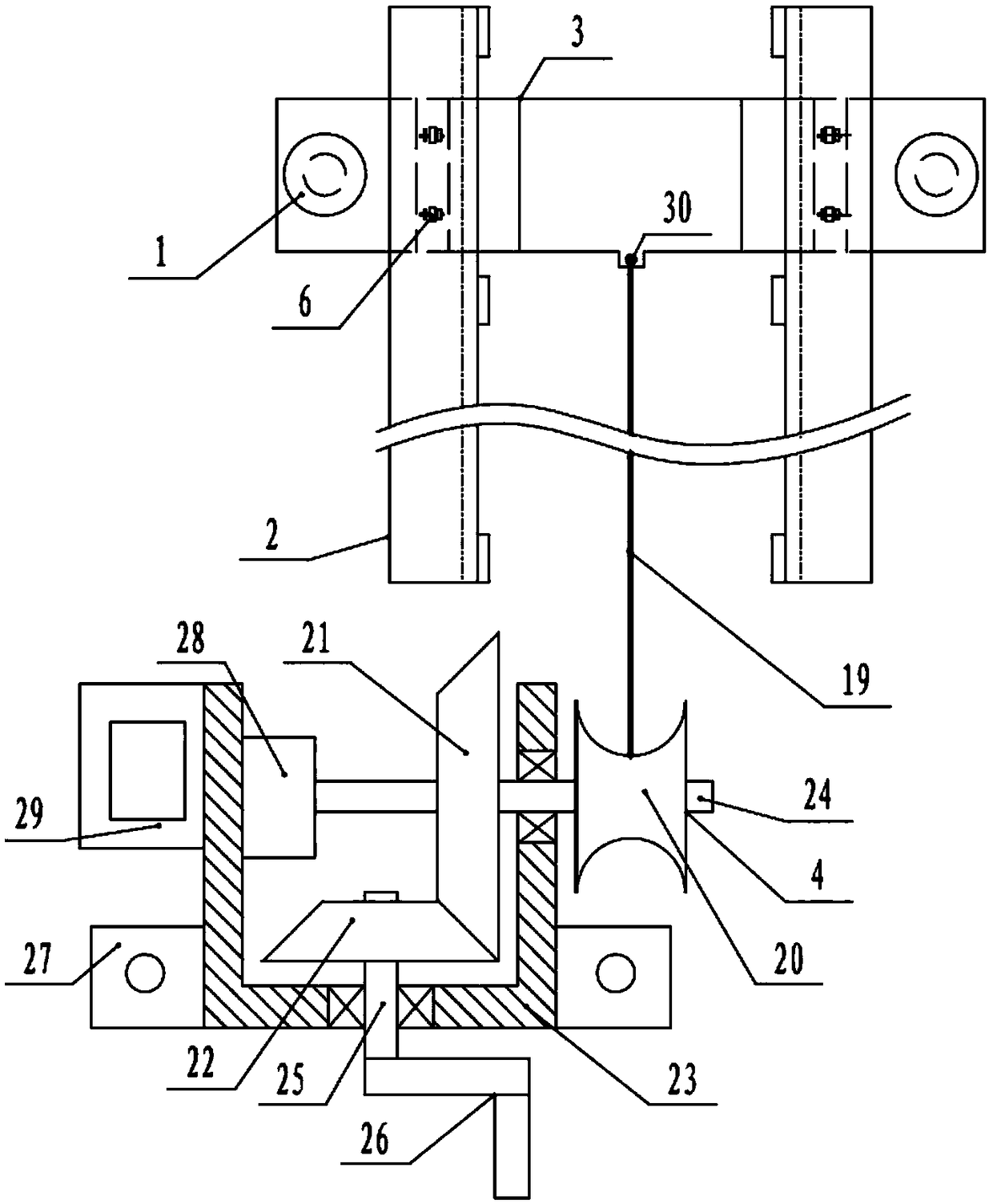

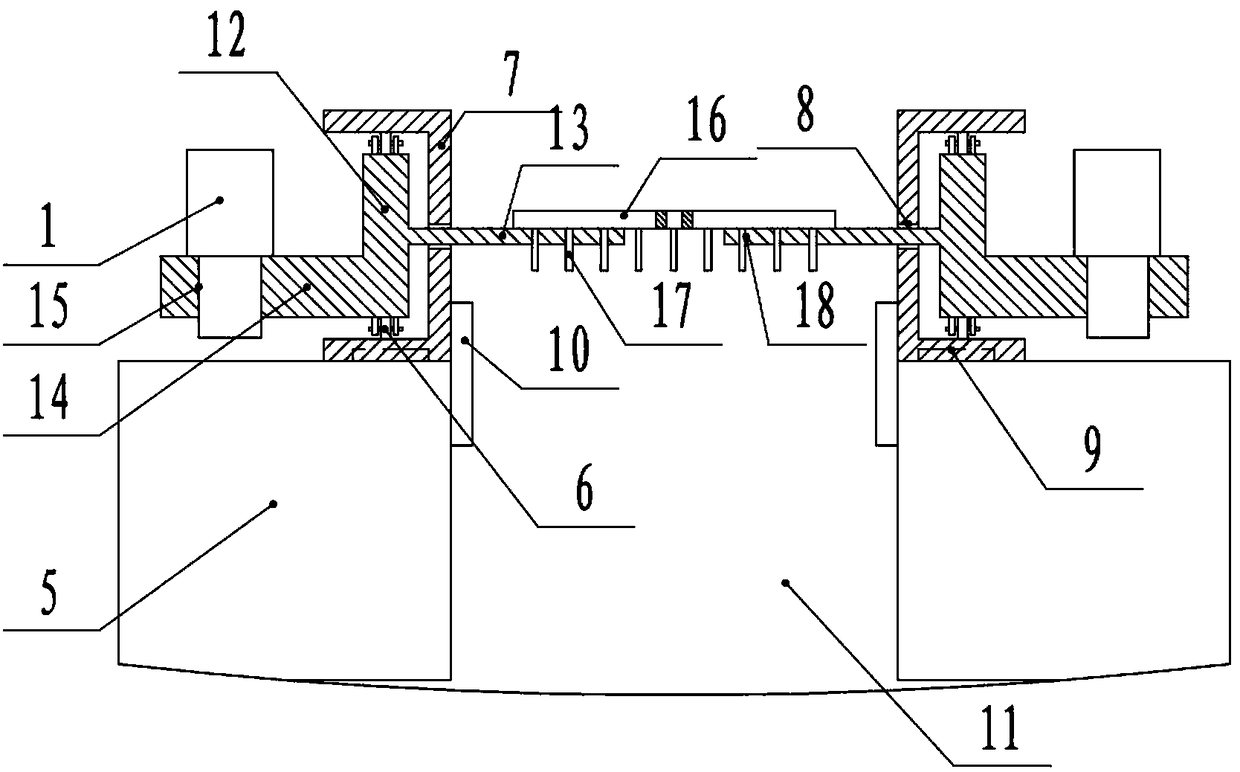

[0044] Embodiment 1: as figure 1 - figure 2 As shown, a generator stator core fault test device includes a Chattock coil 1, a running track 2, a sliding module 3 and a traction device 4. The running track 2 is symmetrically installed on two stator teeth 5, and the sliding module 3 is symmetrically connected to the walking The track 2 is also provided with traveling wheels 6, and the two ends of the sliding module 3 located outside the traveling track 2 are respectively fixedly connected with Chattock coils 1, the sliding module 3 is connected to the traction device 4, and the traction device 4 is fixedly connected outside the stator core.

[0045]Preferably, the above-mentioned walking track 2 includes two channel steel-shaped track bars 7 installed back to back, the bottom of the track bar 7 is provided with a magnet block 9, the middle part of the track bar 7 is provided with a strip-shaped through hole 8, and one end of the middle part of the sliding module 3 is movable. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com