Rock and gas multi-process coupling test device for unconventional natural gas

An unconventional natural gas and test device technology, applied in the field of rock-gas multi-process coupling test device, to achieve strong anti-blocking performance, not easy to block, improve control accuracy and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific embodiments.

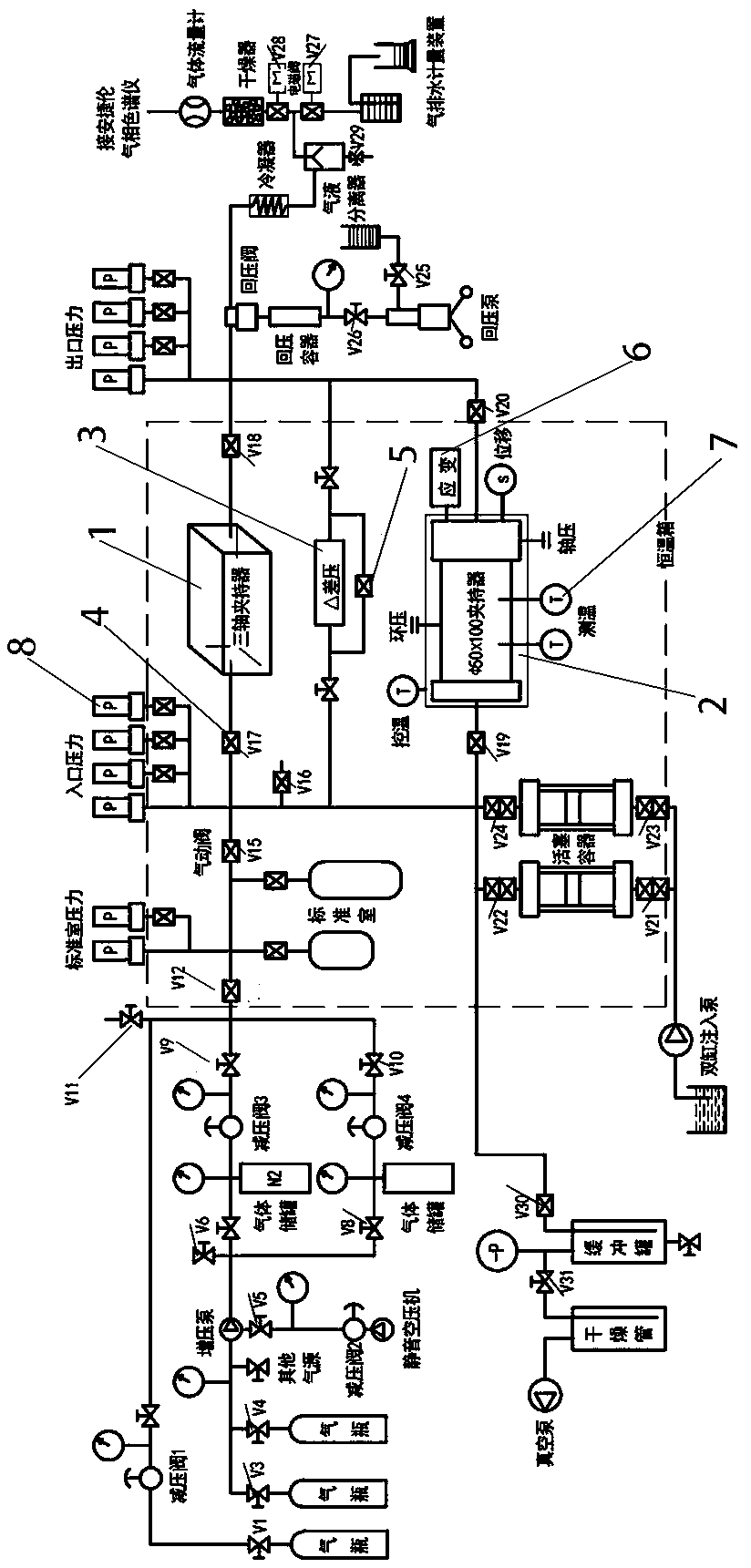

[0011] figure 1 Middle: the first clamping mechanism 1, the second clamping mechanism 2, the differential pressure sensor 3, the first solenoid valve 4, the second solenoid valve 5, the strain sensor 6, the thermometer 7, the pressure testing mechanism 8, among which V3-9, V10~12, V15~20, V21~31 indicate the code of each valve.

[0012] A rock and gas multi-process coupling test device for unconventional natural gas, the test device includes a first clamping mechanism 1, a second clamping mechanism 2, a differential pressure sensor 3, the first clamping mechanism 1, a second clamping mechanism The pipes at both ends of the mechanism 2 are equipped with a first solenoid valve 4, the pipes at both ends of the differential pressure sensor 3 are equipped with manual valves, and the differential pressure sensor 3 is connected in parallel with a second solenoid valve 5. The first cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com