Impeller and centrifugal compressor comprising same

A technology of centrifugal compressors and impellers, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as gap leakage loss, large flow channel eddy current loss, blades that are not easy to work with fluid, and small flow channel section height and width. Achieve the effects of reducing fluid leakage loss and eddy current loss, improving work efficiency, and large channel section aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

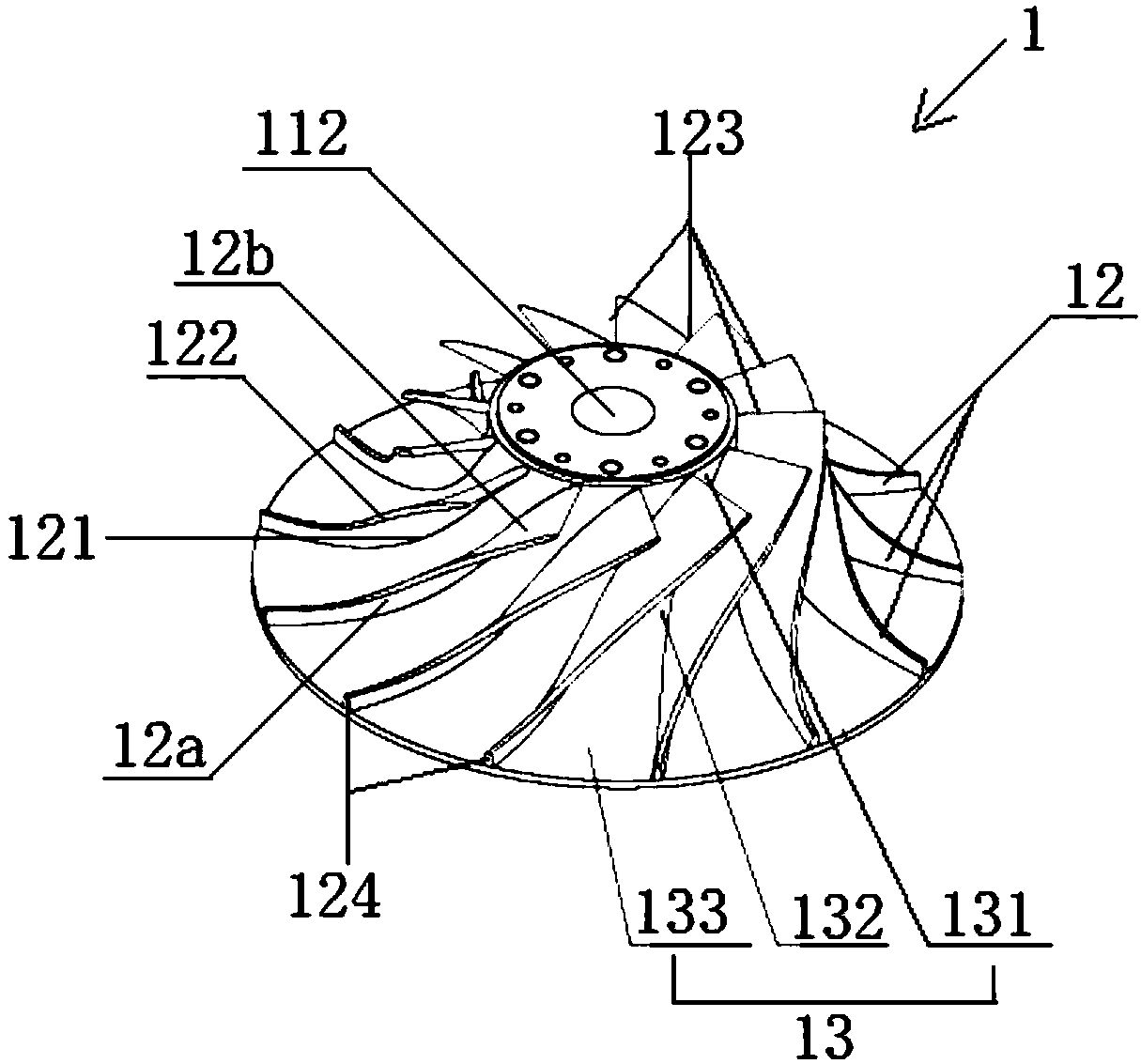

[0066] Both the pressure surface 12a and the suction surface 12b at the tail of the blade 12 in the second embodiment adopt a smooth streamlined curved surface and are combined at the trailing edge 124 to reduce the width of the blade at the outlet of the flow channel and form a narrow streamlined trailing edge to reduce the wake area, thereby reducing wake losses;

Embodiment 3

[0067] The blade of embodiment three is a hollow structure, that is, the part between the pressure surface sheet 12-1 and the suction surface sheet 12-2 of the blade is removed to form a hollow blade with a closed or bifurcated tail, so that the impeller has a lighter weight and better mechanical strength.

[0068] Compared with the prior art, the impeller of the present invention can work at a lower specific speed and has the following characteristics:

[0069] In the case of the same boost and flow rate, it has a lower physical speed;

[0070] In the case of the same flow rate and physical speed, it has a higher boost;

[0071] In the case of the same rotational speed and boost pressure, it can be applied to fluid compression with a smaller flow rate.

[0072] According to experiments, compared with the existing impeller, the impeller of the present invention can reduce the physical speed by 10%-30% under different working conditions under the same pressure boost and flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com