Tunnel top arch free-of-cavity lining method

A top arch and cavity technology, applied in the field of top arch lining, can solve the problem of not being able to observe the pouring situation of the top arch formwork pouring port

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: The observation tube in this embodiment is an integrated observation tube with an integrated camera.

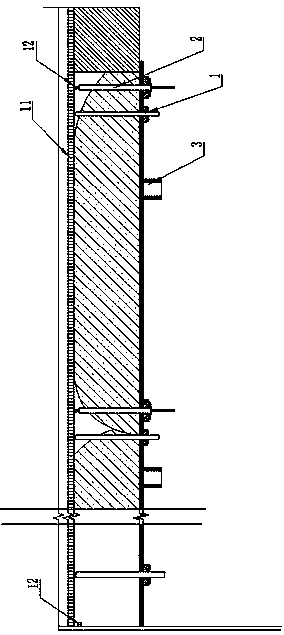

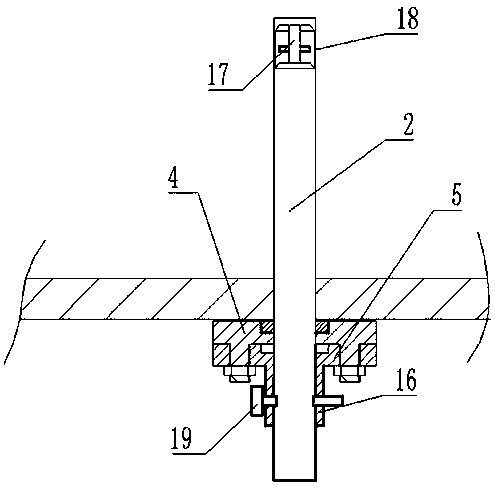

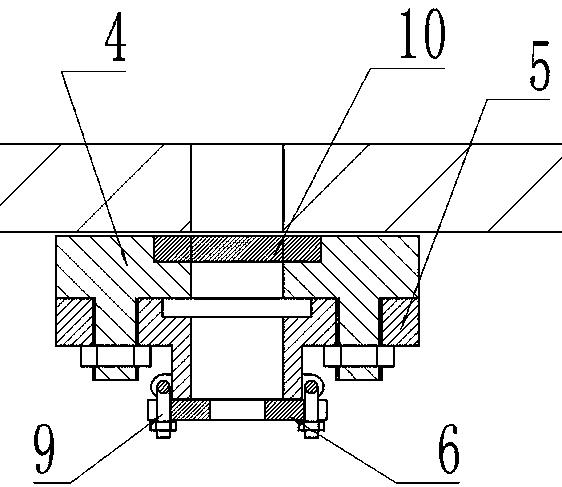

[0035] An observation hole is set on the arch template of the lining trolley, and a closing device 4 is welded under the observation hole. The closing device 4 is composed of a fixed flange and an insert plate 10. The fixed flange is connected with the positioning flange 5 on the observation tube 2 by hinge bolts. , to facilitate the disassembly and assembly of the observation tube 2, the upper end surface of the fixed flange of the closing device 4 is provided with a chute, and an inserting plate 10 is arranged in the chute, the inserting plate 10 is close to the vault formwork, and the inserting plate 10 is used to take out the observation tube 2 , Move the insert plate 10 to block the observation hole, and the concrete will not leak out. There is a positioning tube 16 in the center of the positioning flange 5, and a pin hole is provided on the cylinder...

Embodiment 2

[0052] Embodiment 2: In this embodiment, the end formwork of the trolley is removed, and it is used in the case where both ends of the lining trolley are overlapped and already lined, and the upper end of the observation tube 2 is opened, and the sealing method is adopted from the inside of the tube upward.

[0053] (1) Opening of roof arch formwork for the second lining of the tunnel

[0054] At the highest point of the roof arch formwork of the lining trolley, on the side of the pouring port 3 close to the lining of the upper ring, a distance of 1 lining thickness is added to install the observation pipe 2 and 2 grouting pipes 1 (one of which is the grouting pipe 1 as an intermediate vent or end-die vent or spare grout pipe). General lining trolley roof arch formwork has 4 pouring ports. According to the number of pouring ports, 5 sets of holes are reserved for installing observation pipe 2 and 2 grouting pipes 1, and the middle 3 groups are for installing observation pipe 2...

Embodiment 3

[0068] Embodiment 3: This embodiment is a lining method that does not remove the observation probe 12 at the top of the original end mold. It is used when one end has been lined and overlapped with a ring lining and the other end has not been lined, and the upper end of the observation tube 2 in this embodiment The opening is sealed by pressing down from the outside of the tube. Specific steps are as follows:

[0069] (1) Opening holes in the formwork of the roof arch of the lining platform

[0070] At the highest point of the roof arch formwork of the lining trolley, on the side of each filling port 3 close to the lining of the upper ring, a distance of 1 lining thickness (in order to ensure that the observation tube 2 and the grouting tube 1 are all in the space of the steel bars, The distance is only an approximate value), drill observation holes and grouting holes, add observation tubes 2 and 2 grouting tubes 1 (one of which is used as the middle exhaust pipe or end mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com