Hanging machine for fur and feather processing

A technology of hanging feeder and fur, applied in the direction of leather drying, etc., can solve the problems of affecting economic benefits, high work intensity, and long round-trip time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

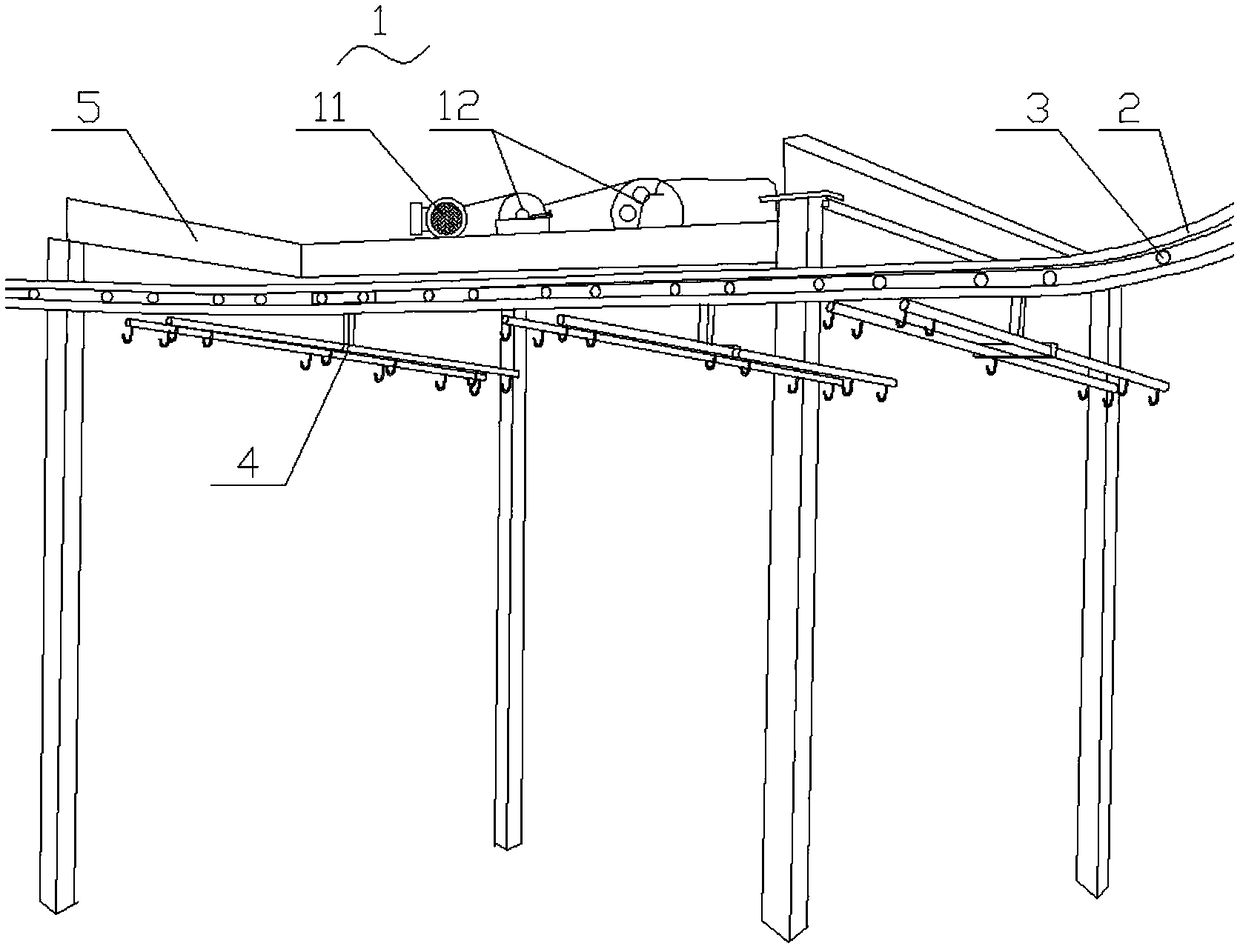

[0020] Such as Figure 1 to Figure 4 As shown, the material hanging machine for fur processing of the present invention includes a power mechanism 1, a guide rail 2, a conveying chain 3 and a material hanging frame 4, and the conveying chain 3 is located in the guide rail 2;

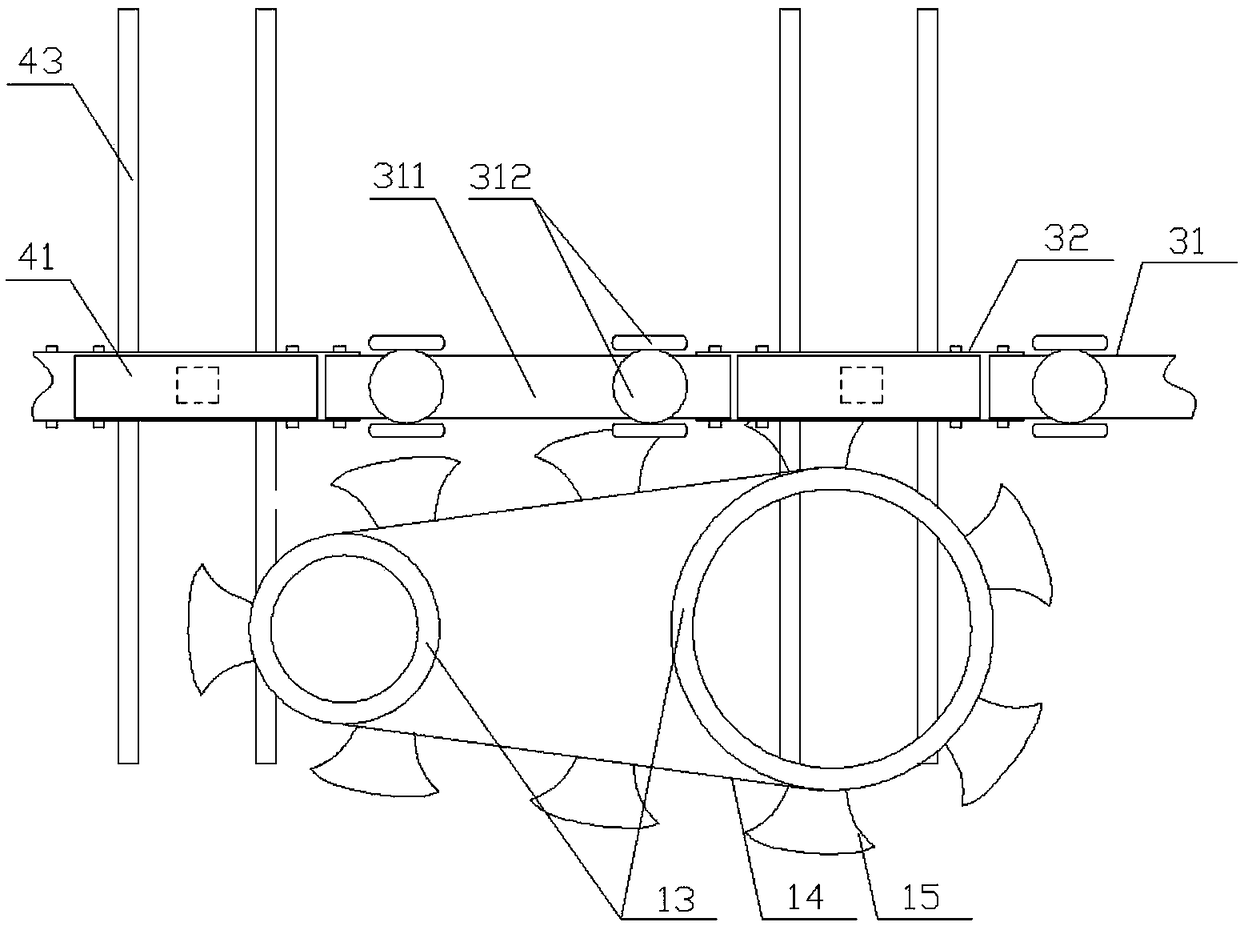

[0021] The power mechanism 1 includes a motor 11 and a reducer 12. The power output end of the reducer 12 drives the transmission chain 14 to rotate through the gear 13. The transmission chain 14 is provided with a claw 15, which is driven by the claw 15 to convey Chain 3 moves forward;

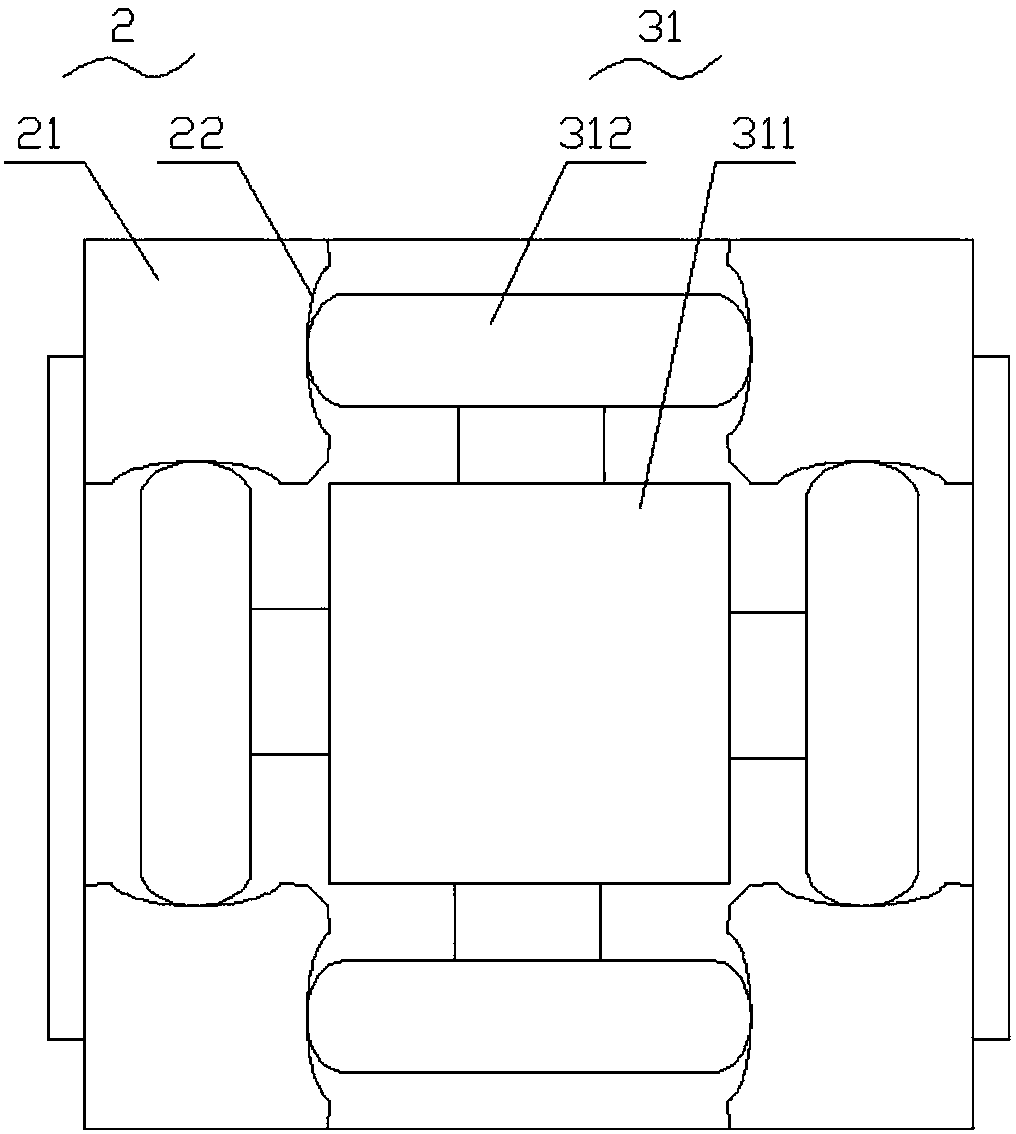

[0022] Described guide rail 2 comprises four slide rails 21, and four slide rails 21 are arranged on the four corners of square respectively, and each slide rail 21 is respectively provided with a chute 22 on two faces opposite to other slide rails 21;

[0023] The conveying chain 3 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com