Gasoline copper plate corrosion inhibitor and preparation method thereof

A technology for copper corrosion and inhibitor, which is used in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve problems such as copper corrosion, and achieve the effects of sufficient reaction, good corrosion prevention, and good dispersion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation of gasoline copper sheet corrosion inhibitor:

[0024] 1) Dissolve 5kg of potassium hydroxide in 15kg of ethanol and stir evenly;

[0025] 2) Add 15kg of sulfonated cobalt phthalocyanine, 2kg of cobalt acetylacetonate, 6kg of sodium benzoate, and 3kg of sodium acetate in sequence, and mix well to get the product.

Embodiment 2

[0027] Preparation of gasoline copper sheet corrosion inhibitor:

[0028] 1) Dissolve 5kg of potassium hydroxide in 15kg of ethanol and stir evenly;

[0029] 2) Add 12kg of sulfonated cobalt phthalocyanine, 3kg of cobalt acetylacetonate, 7kg of sodium benzoate, and 2kg of sodium acetate in sequence, and mix well to get the product.

Embodiment 3

[0031] Preparation of gasoline copper sheet corrosion inhibitor:

[0032] 1) Dissolve 6kg of potassium hydroxide in 18kg of ethanol and stir evenly;

[0033] 2) Add 20kg of sulfonated cobalt phthalocyanine, 2kg of cobalt acetylacetonate, 5kg of sodium benzoate, and 2kg of sodium acetate in sequence, and mix well to get the product.

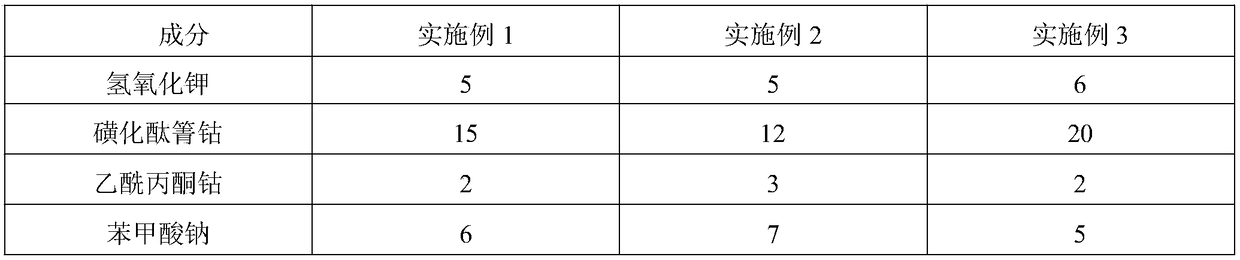

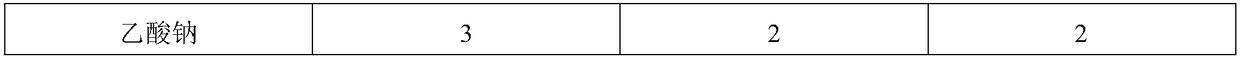

[0034] Table 1 The raw material formula (unit: kg) of gasoline copper sheet corrosion inhibitor

[0035]

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com