Additive applicable to plant-growing concrete and with low alkali, high strength and large porosity

A technology of planting raw concrete and porosity, applied in the field of concrete admixtures, can solve the problems of complex process and high temperature, and achieve the effects of easy availability of raw materials, low alkalinity and simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

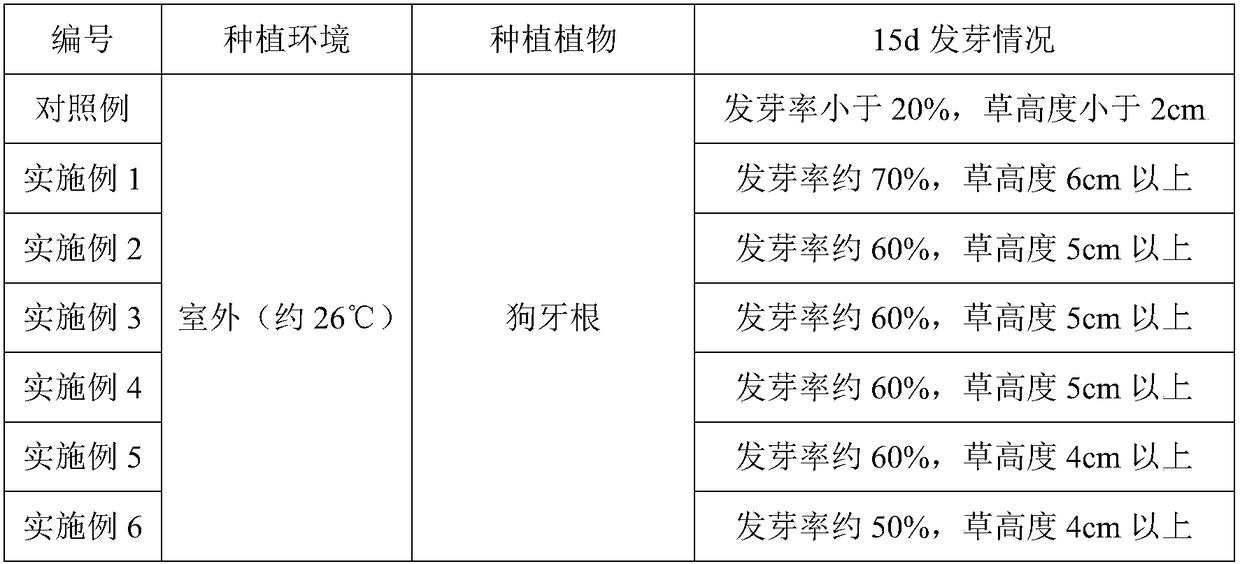

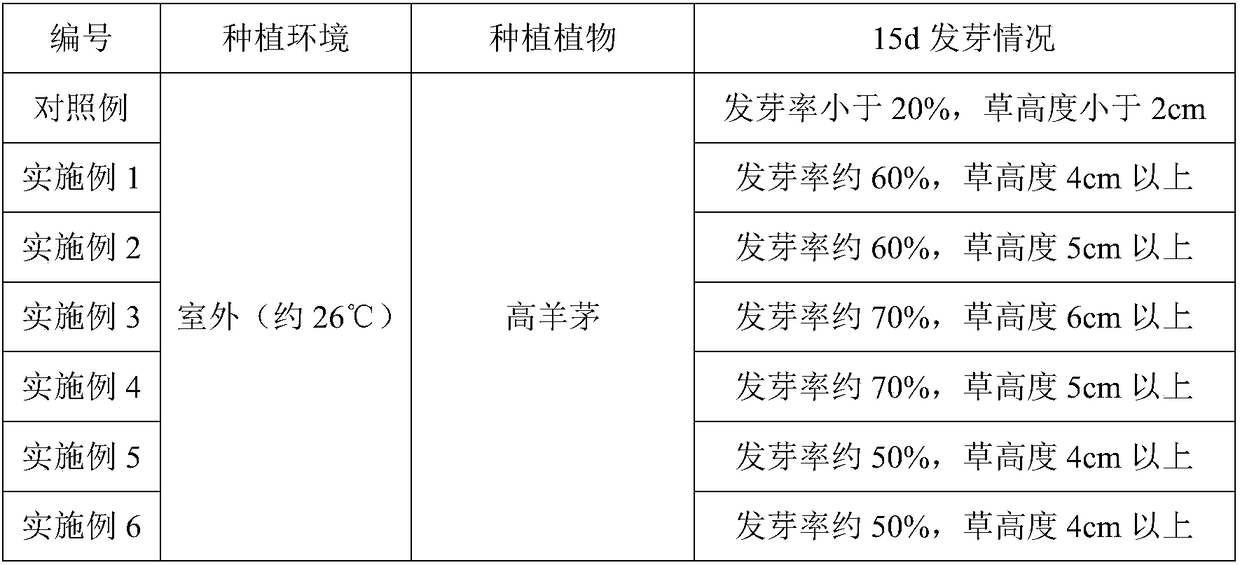

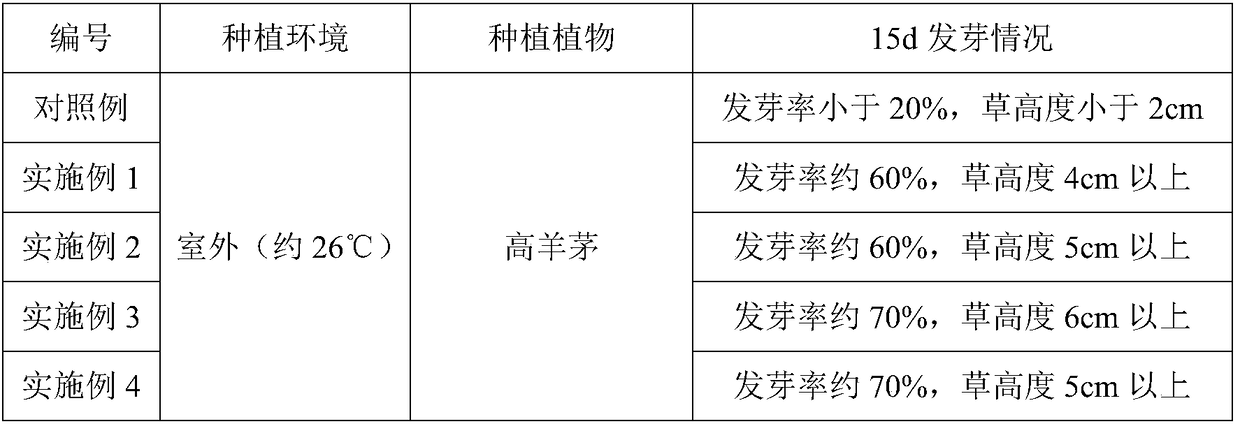

Examples

Embodiment 1

[0021] 45 parts of ether ester copolymerized spray-dried polycarboxylate water reducer (weight average molecular weight is 40000), 3 parts of iron powder (particle size is 600 μm), 20 parts of polyacrylonitrile fiber, 3 parts of potato modified starch, 12 parts of aloe vera powder, 2 parts of Glauber's salt (with a particle size of 1200 μm) and 15 parts of silicon powder were uniformly mixed to obtain the admixture.

Embodiment 2

[0023] Ether ester copolymerization spray drying polycarboxylate superplasticizer (weight average molecular weight is 60000) 46 parts, iron powder (particle diameter is 300 μ m) 1.8 parts, plant fiber 21.5 parts, potato modified starch 3.3 parts, aloe vera powder 13 parts, Glauber's salt ( The particle size is 1200 μm) 2.1 parts, silicon powder 12.3 parts, and the admixture is obtained after uniform mixing.

Embodiment 3

[0025] 46.5 parts of ether-ester copolymerized spray-dried polycarboxylate water reducer (weight average molecular weight: 50,000), 2 parts of iron powder (particle size: 400 μm), 20 parts of high-strength and high-modulus polyvinyl alcohol fiber, 2.8 parts of waxy corn modified starch, aloe vera powder 13.2 parts, Glauber's salt (particle size: 1300 μm) 1.9 parts, silicon powder 13.6 parts, the admixture is obtained after uniform mixing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com