Intelligent all-coverage bulk material unloading distributor

A full-coverage, distribution machine technology, applied in the field of distribution machines, can solve the problems of dead corners of the stacking coverage area and low automation of the distribution machine, and achieve the effects of reducing dust, simple structure, and ensuring continuity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

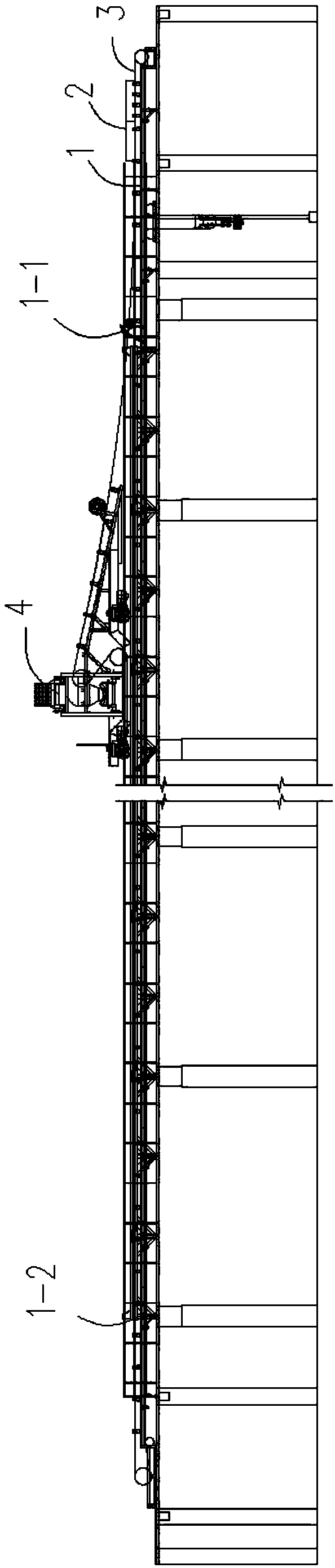

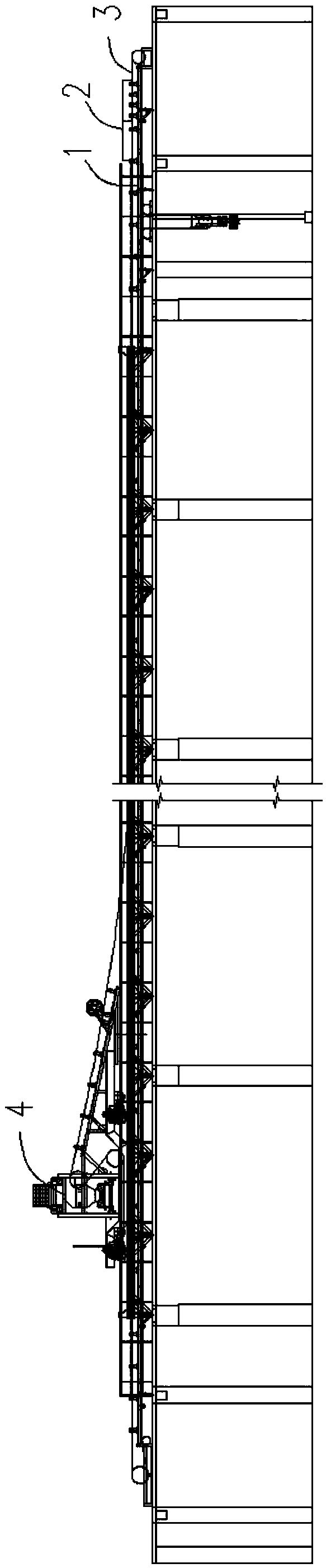

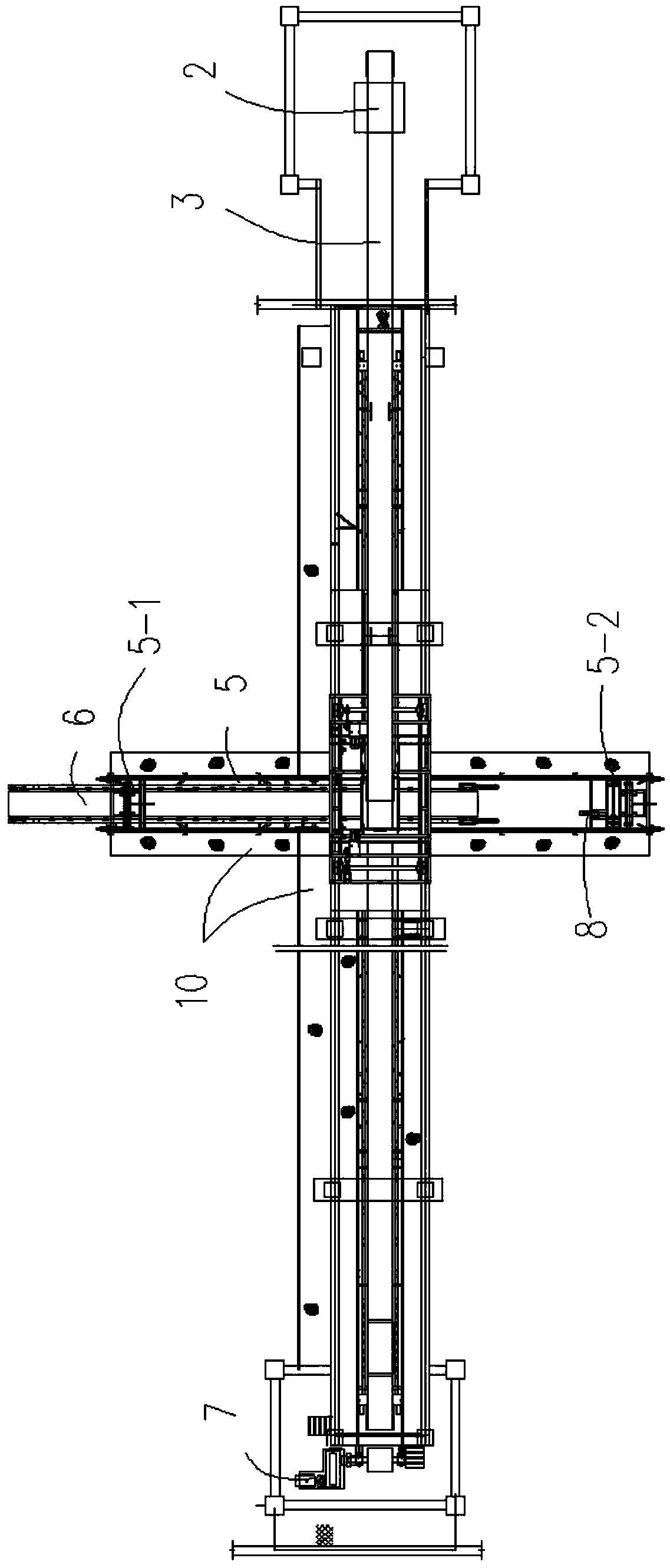

[0032] Such as Figures 1 to 8 As shown, this embodiment provides an intelligent full-coverage bulk material unloading and distributing machine, including a horizontal conveyor frame 1 fixedly installed in the warehouse. The warehouse cooperates with the feed port 2, and it is characterized in that the horizontal conveying frame 1 is provided with an unloading vehicle 4 that reciprocates along the horizontal conveying frame 1, and the unloading vehicle 4 is provided with a The delivered longitudinal conveyor frame 5 is provided with a discharge belt mechanism 6 that can move back and forth along the longitudinal conveyor frame 5, and the longitudinal conveyor frame 5 is provided with a limit mechanism that limits the front and rear limit positions of the discharge belt mechanism 6. A5-1 and the limit mechanism B5-2, the limit mechanism C1-1 and the limit mechanism D1-2 that limit the left and right limit positions of the unloading vehicle 4 are also arranged on the transverse ...

Embodiment 2

[0035] This implementation has been optimized as follows on the basis of Embodiment 1, specifically:

[0036] The described unloading truck 4 is provided with a dust suppression spray mechanism 9, and the dust suppression spray mechanism 9 includes a water tank 9-1 and a spray system 9-2 connected to the water tank 9-1 through a pipeline, and the spray system 9- 2 includes the main spraying pipeline 9-2.1 and a plurality of branch spraying pipelines 9-2.2 connected with the main spraying pipeline 9-2.1, and each branch spraying pipeline 9-2.2 is evenly distributed with a number of atomizing nozzles 9-2.3.

[0037] The dust-reducing spray mechanism is installed in the unloading vehicle. For the bulk mixture with powder, the forced water spraying on the throwing point can greatly reduce the dust generated during unloading and reduce the pollution to the surrounding environment. At the same time, the loss of materials is also reduced.

Embodiment 3

[0039] This embodiment is further optimized on the basis of embodiment 1 or 2, specifically:

[0040] The limiting mechanism A5-1 and the limiting mechanism B5-2, the limiting mechanism C1-1 and the limiting mechanism D1-2 all include an infrared sensor and a limiting baffle.

[0041] The both sides of described transverse conveying frame 1 and longitudinal conveying frame 5 are all provided with safety fence 10

[0042] It also includes a main controller, and the horizontal conveying frame 1 is also provided with a driving mechanism for driving the unloading vehicle 4 to move along the horizontal conveying frame 1, and also includes a device for controlling one end of the horizontal conveying frame 1 to drive the horizontal conveyor belt 3 to move. The horizontal conveyor motor 7, the discharge belt mechanism 6 is provided with a vertical discharge motor 8 that drives the discharge belt movement, the drive mechanism, the horizontal conveyor motor 7, the vertical discharge mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com