Fire-resistant cable hatch deck

A hatch cover and hatch cover technology, applied in the field of hatch covers, can solve the problems of easy wear and tear of cables and hatches, fire protection of hatch covers, poor weathertight performance, loss of fire resistance, weathertight performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

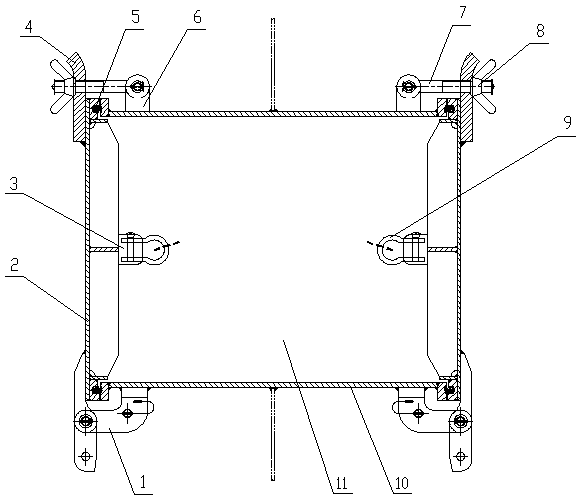

[0012] like figure 1 As shown, the fireproof cable hatch cover of the present invention includes a hatch 11 and a hatch cover 2 . A cylindrical coaming 10 whose length is adapted to the thickness of the bulkhead is installed in the hatch 11 , and the hatch cover 2 is arranged at both ends of the cylindrical coaming 10 . The lower sides of the two hatches 2 are respectively hinged to the lower sides of the two ends of the tubular coaming 10 by means of hinges 1 , so that the hatches 2 can be turned outward around the hinges 1 . There is a locking mechanism between the upper edge of the hatch cover 2 and the upper edge of the corresponding end of the cylindrical coaming plate 10 .

[0013] Described locking mechanism contains a locking platelet 4, and the plate face of locking platelet 4 is parallel with the outer surface of hatch cover 2, and one end of locking platelet 4 is welded on the outer surface edge of hatch cover 2, locks The other end of small plate 4 is processed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com