Laser guiding type robot charging pile

A laser-guided and robotic technology, applied in charging stations, electric vehicle charging technology, electric vehicles, etc., can solve the problems that the price of infrastructure construction affects the process of industrialization, does not form an economic scale, and the purchase price is relatively expensive. Unable to dock, fast and effective charging, and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

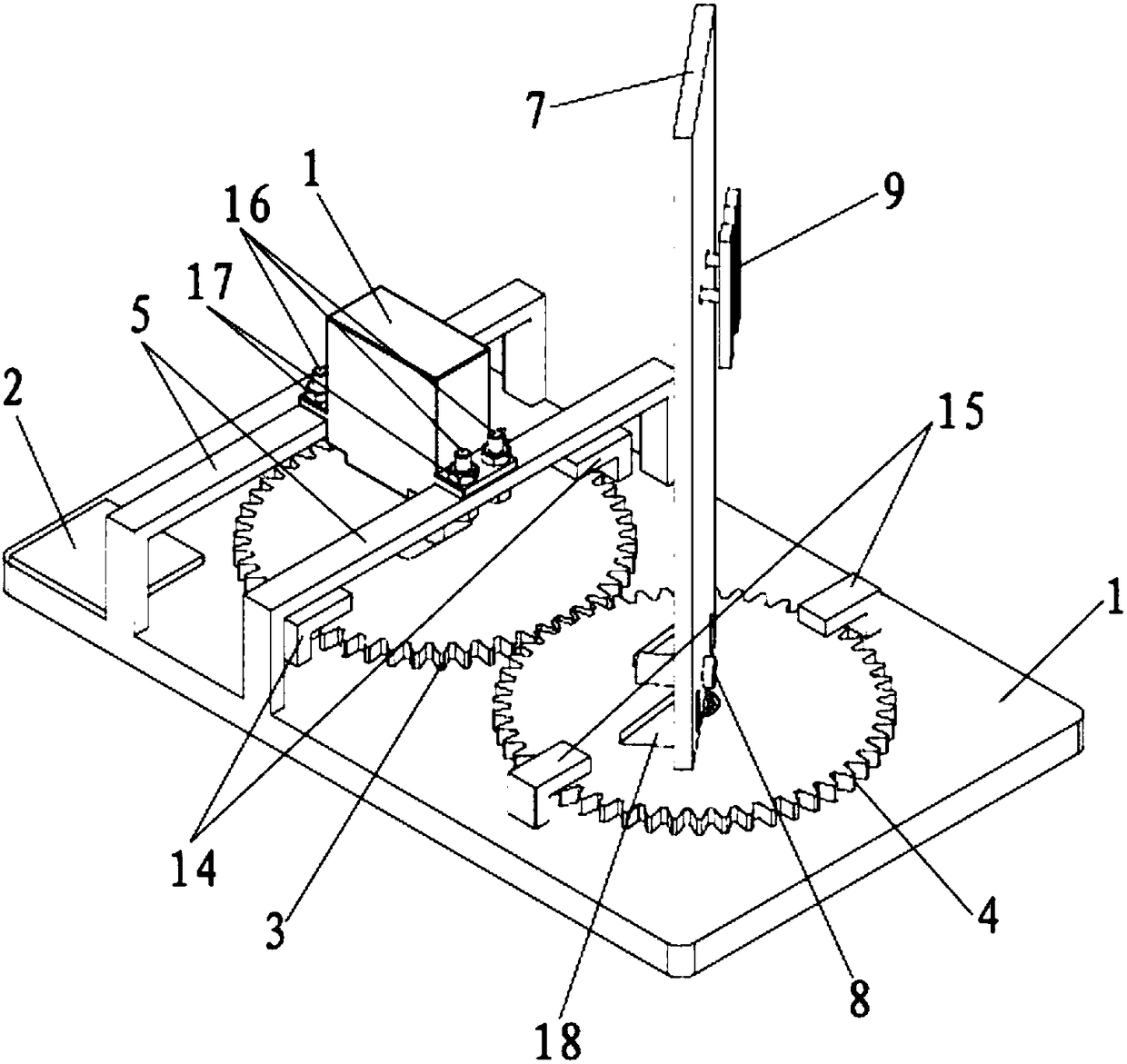

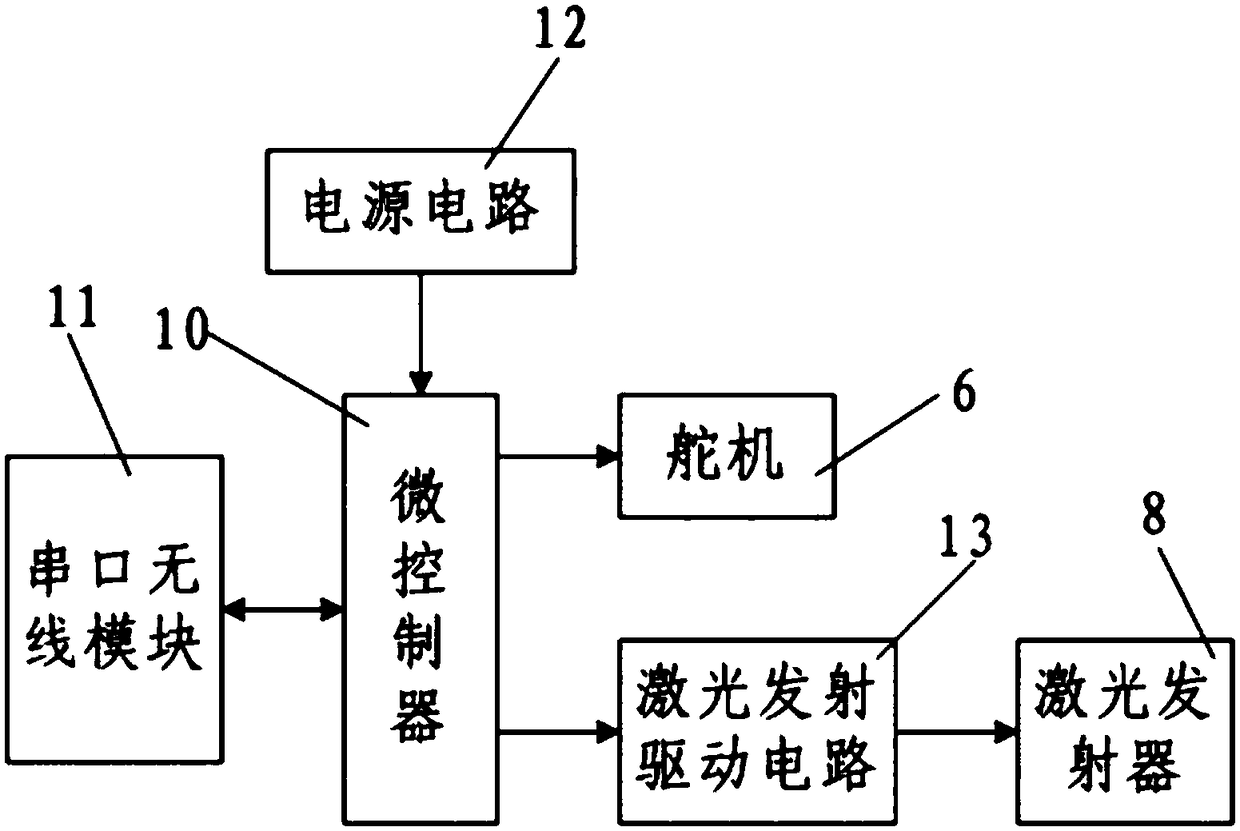

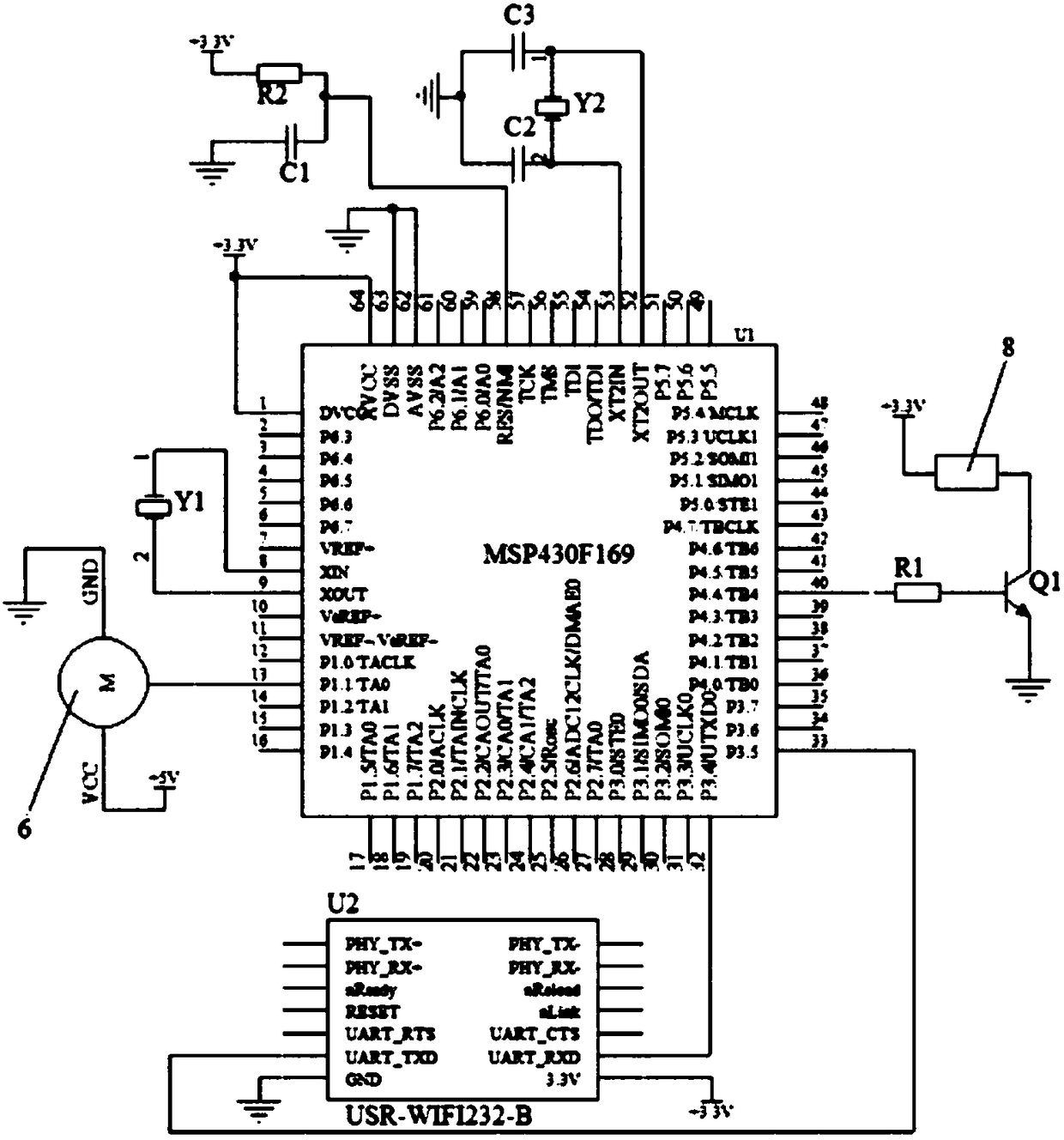

[0031] like figure 1 As shown, the present invention includes a base 1 and a laser guide control circuit board 2 installed on the base 1, and a first gear 3 and a second gear 4 that are rotatably connected to the base 1 and engaged with each other, and the base 1 is passed through the rudder The machine bracket is fixedly connected with a steering gear 6 located above the first gear 3, the first gear 3 is fixedly connected with the output shaft of the steering gear 6, and the second gear 4 is fixedly connected with a power insertion baffle 7, the The bottom of the power supply insertion baffle 7 is fixedly connected with the laser transmitter 8 used in conjunction with the laser receiver installed on the robot, and the top of the power insertion baffle 7 is fixedly connected with a power socket 9 connected to the mains; The laser guidance control circuit board 2 is integrated with a laser guidance control circuit, combined with figure 2 , the laser guidance control circuit i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com