Multipurpose testing filer paper cutting device and method

A cutting device and a technology for testing, applied in metal processing, etc., can solve problems such as time-consuming, labor-intensive irregularities, etc., and achieve the effects of low processing cost, controllable cost and high quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

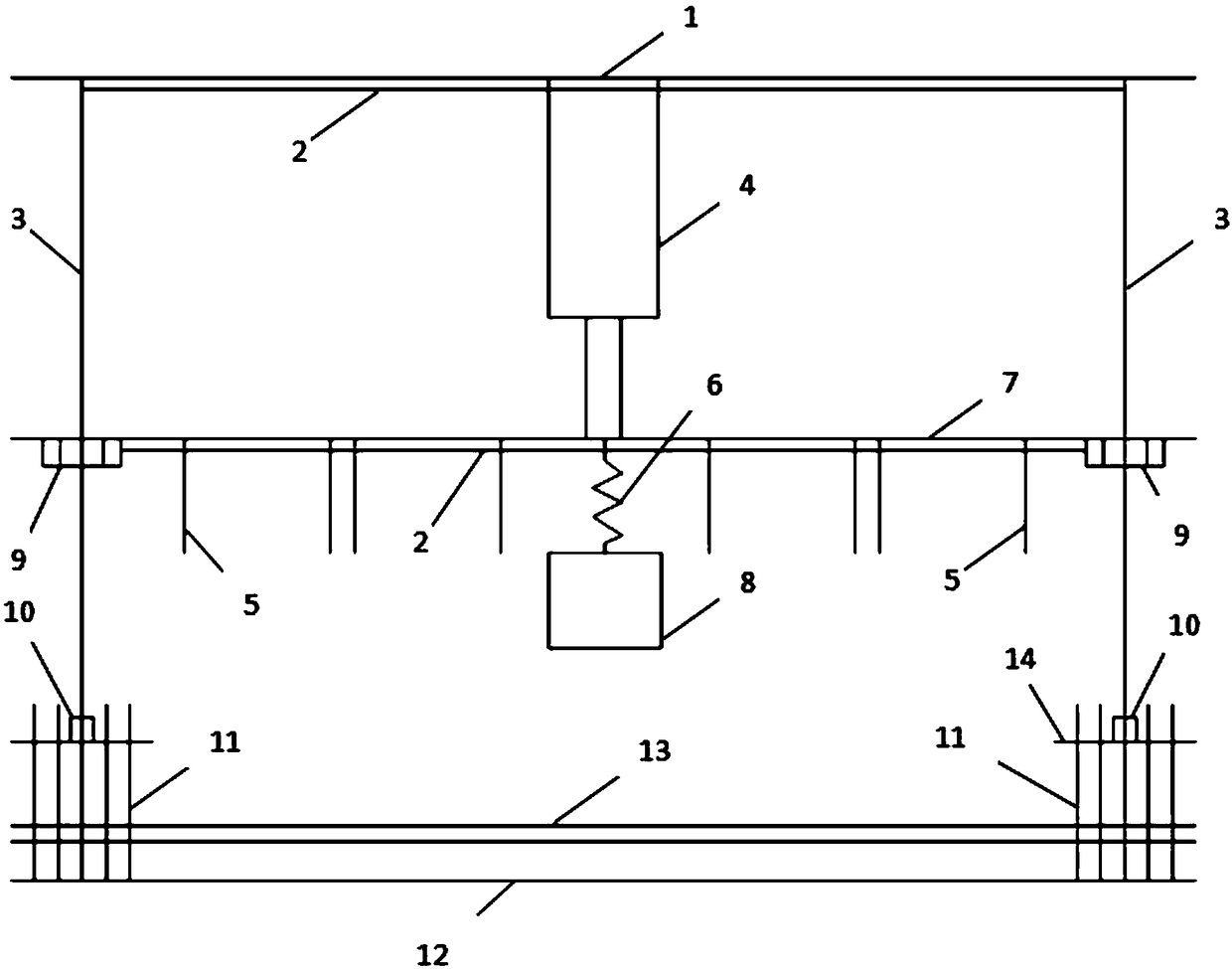

[0030] Such as figure 1 As shown, a multi-purpose test filter paper cutting device includes a circular top plate 1, a horizontal plate 7, a circular bottom plate 12 and two vertical bars 2, and the circular top plate 1, horizontal plate 7, and circular bottom plate 12 are from top to bottom The bottom is arranged in parallel in turn, and the two vertical rods 2 are connected to the left and right sides between the circular top plate 1 and the circular bottom plate 12; the vertical rods 2 are thinner overall, which is convenient to pass through the edge of the filter paper 13 to be cut, and then fix the filter paper 13 to be cut . A jack 4 is provided at the bottom of the circular top plate 1, and the jack 4 is located between the circular top plate 1 and the horizontal plate 7. The jack 4 has a telescopic rod facing the horizontal plate 7, and the jack 4 drives the telescopic movement of the telescopic rod to drive the horizontal plate 7 to move horizontally. , the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com