Die-casting machine for plug-and-socket fasteners

A technology of die-casting machine and buckle, which is applied in the field of molding equipment, can solve the problems of wasting materials and processing man-hours, low processing efficiency, complex processing technology, etc., and achieve the effect of improving pulling force, simple structure, and smooth left and right movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

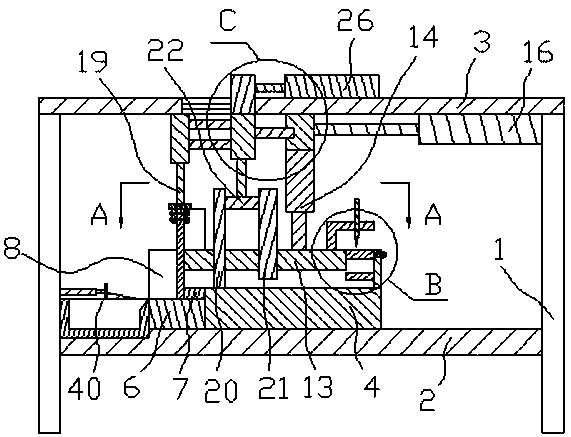

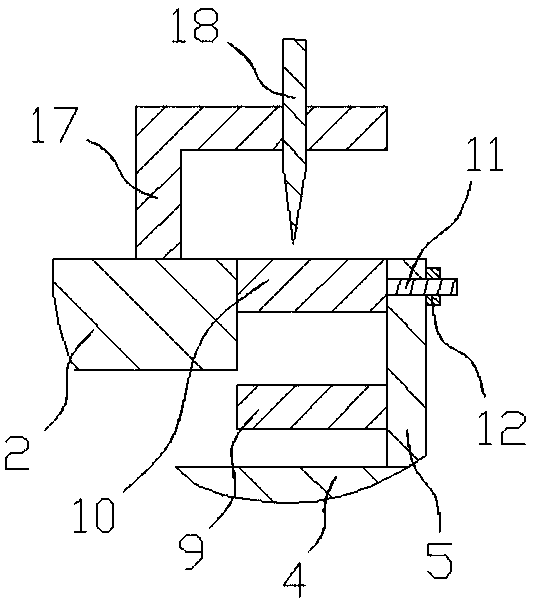

[0033] like Figure 1-Figure 8 As shown, the specific structure of the present invention is: a die-casting machine for socket fasteners, including a frame 1, the frame 1 is provided with a lower working plate 2 and an upper working plate 3, and the lower working plate 2 is provided with a lower module with side plates on the front and rear right sides, the inner side of the right side plate of the lower module is provided with a jaw forming block 9 and a jaw forming cover plate 10, and the lower part of the upper working plate 3 is provided with a A briquetting lifting cylinder 14, the upper mold briq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com