Crusher capable of conveniently adjusting crushing size

A crusher and crushing cylinder technology, applied in the direction of grain processing, etc., can solve the problems of different sizes of materials, time-consuming and labor-intensive, uneven hardness, etc., and achieve the effect of high safety performance, good crushing effect, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

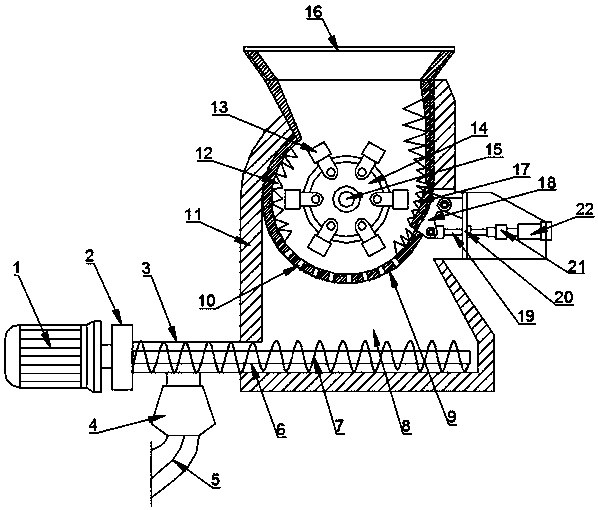

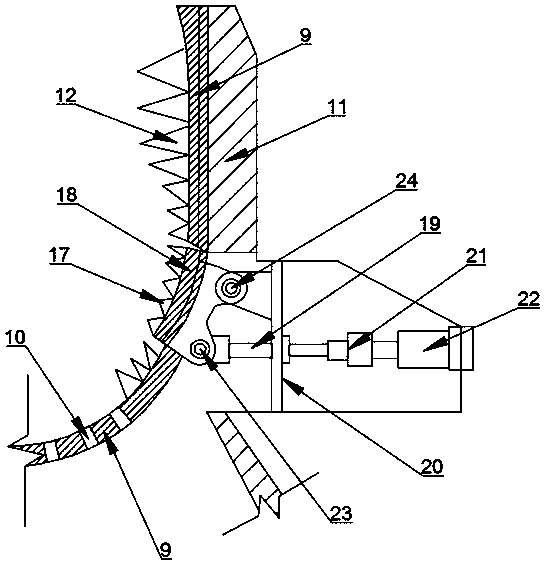

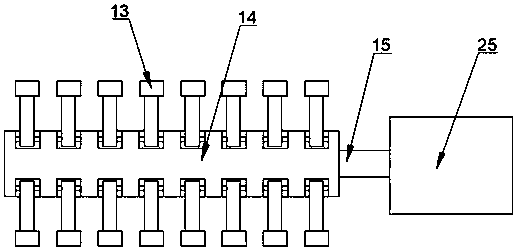

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0021] see Figure 1-3 , a kind of crusher that is convenient to adjust the crushing size, including a discharge pipe 3, a crushing cylinder 9, a crusher shell 11, a fixed hammer 12, a rotary hammer 13, a feed hopper 16, a movable hammer 17 and a movable block 18, the crushing A crushing cylinder 9 is installed inside the casing 11, and an opening is provided on the upper side of the crushing cylinder 9. The upper end of the crushing cylinder 9 is connected to a feed hopper 16, and the feed hopper 16 is fixed on the top of the crushing casing 11. The inner wall of the crushing cylinder 9 is welded with A number of fixed hammers 12, a crushing roller 14 is installed inside the crushing cylinder 9, the roller shaft 15 of the crushing roller 14 is erected on the crusher casing 11, and one end of the roller shaft 15 passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com