Preparation and application of carbon-supported palladium-tin nano-alloy catalyst in electrocatalytic reduction of carbon dioxide

A technology of nano-alloy and carbon dioxide, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, electrode, etc., can solve the problem of low formic acid selectivity, and solve the problem of low formic acid selectivity and preparation The method is simple and the effect of high application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

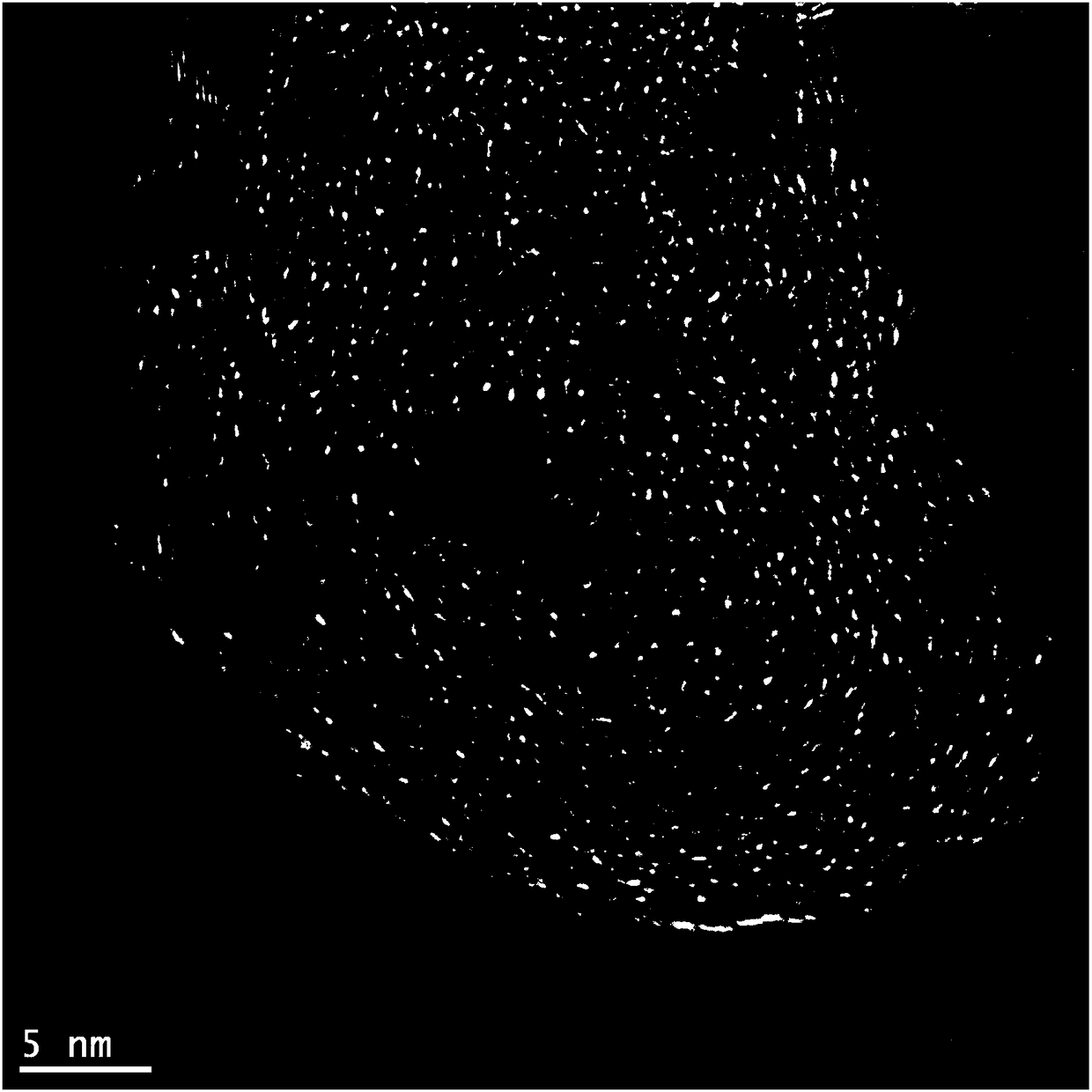

Image

Examples

Embodiment 1

[0048]Get palladium acetate, tin acetate, wherein the molar ratio of Pd in palladium acetate and Sn in tin acetate is 1:5, add 500mg carbon nanotubes and mix for the first time, wherein the mass of Pd in palladium acetate and carbon nanotubes The ratio is 10:100 (10%), and the mixture is sonicated in an ultrasonic machine for 1h. Then add 5g of PVA as a stabilizer and 20ml of 0.5M ethylene glycol as a reducing agent for the second mixing, and stir vigorously for 5 hours at a temperature of 25°C. After the second mixing and centrifugation, the solid product was washed three times with deionized water, and vacuum-dried at 50° C. for 24 hours to obtain a carbon-supported palladium-tin nano-alloy catalyst. The catalyst is used for the potentiostatic reduction of CO 2 , the applied voltage is -1.45V, and the reaction time is 1h, the products of hydrogen, carbon monoxide and formic acid are obtained, and the faradaic current efficiency of formic acid reaches 81.0%, which has go...

Embodiment 2

[0050] Get palladium chloride, tin acetate, wherein the molar ratio of the Pd in the palladium chloride and the Sn in the tin acetate is 1:5, add 500mg nano-carbon tubes and mix for the first time, wherein the Pd in the palladium chloride and the nano-carbon The mass ratio of the tube is 10:100 (10%), and the mixture is sonicated in an ultrasonic machine for 1h. Then add 5g of PVA as a stabilizer and 20ml of 0.5M ethylene glycol as a reducing agent for the second mixing, and stir vigorously for 5 hours at a temperature of 25°C. After the second mixing and centrifugation, the solid product was washed three times with deionized water, and vacuum-dried at 50° C. for 24 hours to obtain a carbon-supported palladium-tin nano-alloy catalyst. The catalyst is used for the potentiostatic reduction of CO 2 , the applied voltage is -1.61V, and the reaction time is 1h, the products of hydrogen, carbon monoxide and formic acid are obtained, and the faradaic current efficiency of formic...

Embodiment 3

[0052] Get palladium acetate, stannous chloride, wherein the molar ratio of the Pd in the palladium acetate and the Sn in the stannous chloride is 1:5, add 500mg carbon nanotubes and mix for the first time, wherein the Pd in the palladium acetate and the nanometer The mass ratio of the carbon tubes is 10:100 (10%), and the mixture is sonicated in an ultrasonic machine for 1 hour. Then add 5g of PVA as a stabilizer and 20ml of 0.5M ethylene glycol as a reducing agent for the second mixing, and stir vigorously for 5 hours at a temperature of 25°C. After the second mixing and centrifugation, the solid product was washed three times with deionized water, and vacuum-dried at 50° C. for 24 hours to obtain a carbon-supported palladium-tin nano-alloy catalyst. The catalyst is used for the potentiostatic reduction of CO 2 , the applied voltage is -1.72V, and the reaction time is 1h, the products of hydrogen, carbon monoxide and formic acid are obtained, and the faradaic current ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com