DCB (double-cantilever beam) fracture toughness testing device

A fracture toughness and testing device technology, applied in the field of oil and gas drilling engineering, can solve the problems of inability to measure the propagation velocity, fracture displacement and extension length of I-type cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] In order to achieve the above object, the technical scheme adopted in the present invention is:

[0095] Such as figure 1 As shown, a double cantilever beam fracture toughness test device is used in the double cantilever beam fracture toughness test method for inducing intrinsic sharp cracks. The structure includes a mechanical transmission system, an electronic acquisition system and a data terminal processing system. The mechanical transmission system is fixed on the bearing beam 11, the electronic collection system is directly connected to the mechanical transmission system, and the data terminal processing system is directly connected to the electronic collection system.

[0096] The mechanical transmission system mainly includes a sample clamping member, a tension transmission mechanism and a pressure transmission mechanism.

[0097] The sample clamping member is arranged laterally on the upper part of the tension transmission member and axially on the lower part ...

Embodiment 2

[0164] The difference from the examples is that three samples of the research plate were prepared, and three evaluation tests were carried out to ensure the accuracy of the test results and evaluation results. The test methods and steps were the same as in Example 1.

Embodiment 3

[0166] In order to achieve the above object, the technical scheme adopted in the present invention is:

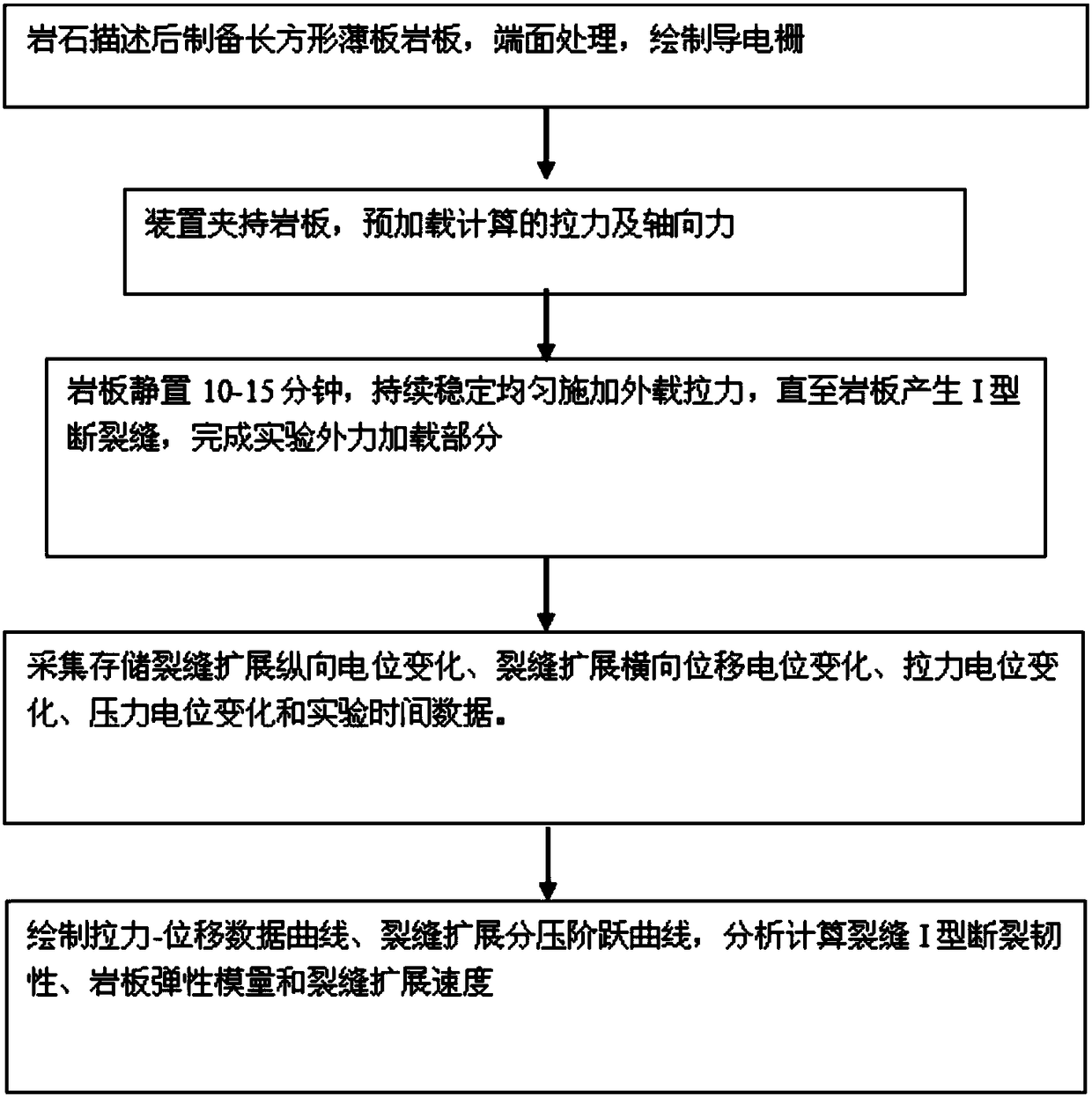

[0167] Such as figure 2 As shown, the double cantilever beam fracture toughness test method of the double cantilever beam fracture toughness test device induced intrinsic sharp cracks, which includes the following steps in order:

[0168] Step 1: Prepare rectangular thin slate slabs from rocks, end-face treatment, and draw conductive grids;

[0169] Step 2: The device clamps the rock slab, and preloads the calculated tensile force and axial force;

[0170] Step 3: The slab is left to stand for 10-15 minutes, and the external tensile force is applied continuously and evenly until the slab produces Type I fracture cracks, and the external force loading part of the experiment is completed;

[0171] Step 4: Collect and store the longitudinal potential change of crack expansion, the lateral displacement potential change of crack expansion, the tension potential change, the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com