Closed type cooling and waste heat recovery device for sintering ores

A sintered and closed technology, applied in lighting and heating equipment, waste heat treatment, treatment of discharged materials, etc., can solve the problems of large changes and difficult project implementation, to eliminate interference, improve the efficiency of waste heat recovery, and improve the exchange rate. Effect of Heat Rate and Waste Heat Quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

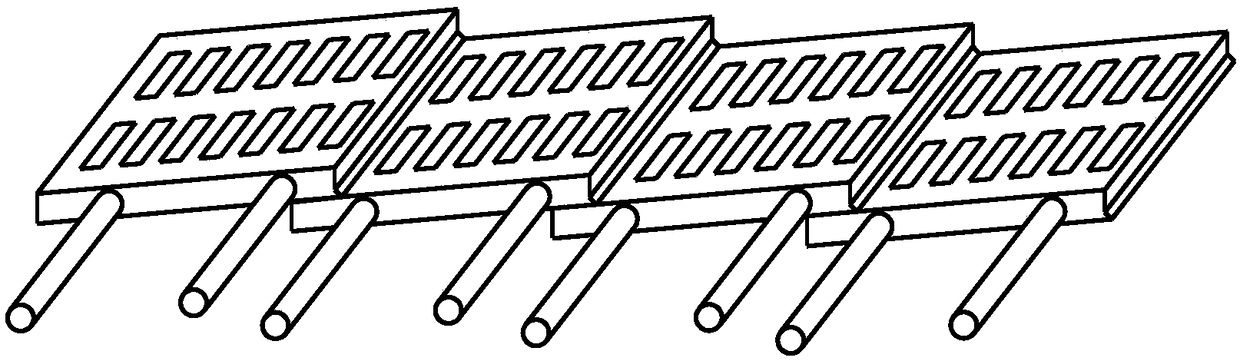

Image

Examples

Embodiment 1

[0025] A closed sinter cooling and waste heat recovery equipment, including a material inlet, a material outlet, a fan, a conveying plate, an air circulation pipe and a cooling chamber, the cooling chamber shell is a closed shell, the conveying plate is inside the cooling chamber, and the conveying plate The sintered ore is transported from the material inlet to the material outlet, and the fan includes an induced draft fan and a blower;

[0026] There are 4 cooling chambers, namely the first cooling chamber, the second cooling chamber, the third cooling chamber and the fourth cooling chamber;

[0027] There is an air distribution hood under the cooling chamber, and an air collecting hood is connected above;

[0028] Starting from the end of the fourth cooling chamber, the air collecting hood above the cooling chamber is connected with the air distribution hood below the previous adjacent cooling chamber by an air circulation pipe, and an induced draft fan is provided;

[002...

Embodiment 2

[0036] A closed sinter cooling and waste heat recovery equipment, including a material inlet, a material outlet, a fan, a conveying plate, an air circulation pipe and a cooling chamber, the cooling chamber shell is a closed shell, the conveying plate is inside the cooling chamber, and the conveying plate The sintered ore is transported from the material inlet to the material outlet, and the fan includes an induced draft fan and a blower;

[0037] There are 4 cooling chambers, namely the first cooling chamber, the second cooling chamber, the third cooling chamber and the fourth cooling chamber;

[0038] There is an air distribution hood under the cooling chamber, and an air collecting hood is connected above;

[0039] Starting from the end of the fourth cooling chamber, the air collecting hood above the cooling chamber is connected with the air distribution hood below the previous adjacent cooling chamber by an air circulation pipe, and an induced draft fan is provided;

[0040]...

Embodiment 3

[0044] A closed sinter cooling and waste heat recovery equipment, including a material inlet, a material outlet, a fan, a conveying plate, an air circulation pipe and a cooling chamber, the cooling chamber shell is a closed shell, the conveying plate is inside the cooling chamber, and the conveying plate The sintered ore is transported from the material inlet to the material outlet, and the fan includes an induced draft fan and a blower;

[0045] There are 4 cooling chambers, namely the first cooling chamber, the second cooling chamber, the third cooling chamber and the fourth cooling chamber;

[0046] Starting from the end of the fourth cooling chamber, the air collecting hood above the cooling chamber is connected with the air distribution hood below the previous adjacent cooling chamber by an air circulation pipe, and an induced draft fan is provided;

[0047] The transmission plate is made of iron plates with the same shape and material. The thickness of the transmission p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com