Gas output pipeline of liquid natural gas storage tank

A technology for liquefied natural gas and output pipelines, applied in fixed-capacity gas storage tanks, gas/liquid distribution and storage, container discharge methods, etc., can solve problems such as accelerating heat conduction and reducing frost, so as to speed up heat conduction, reduce frost, and heat uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

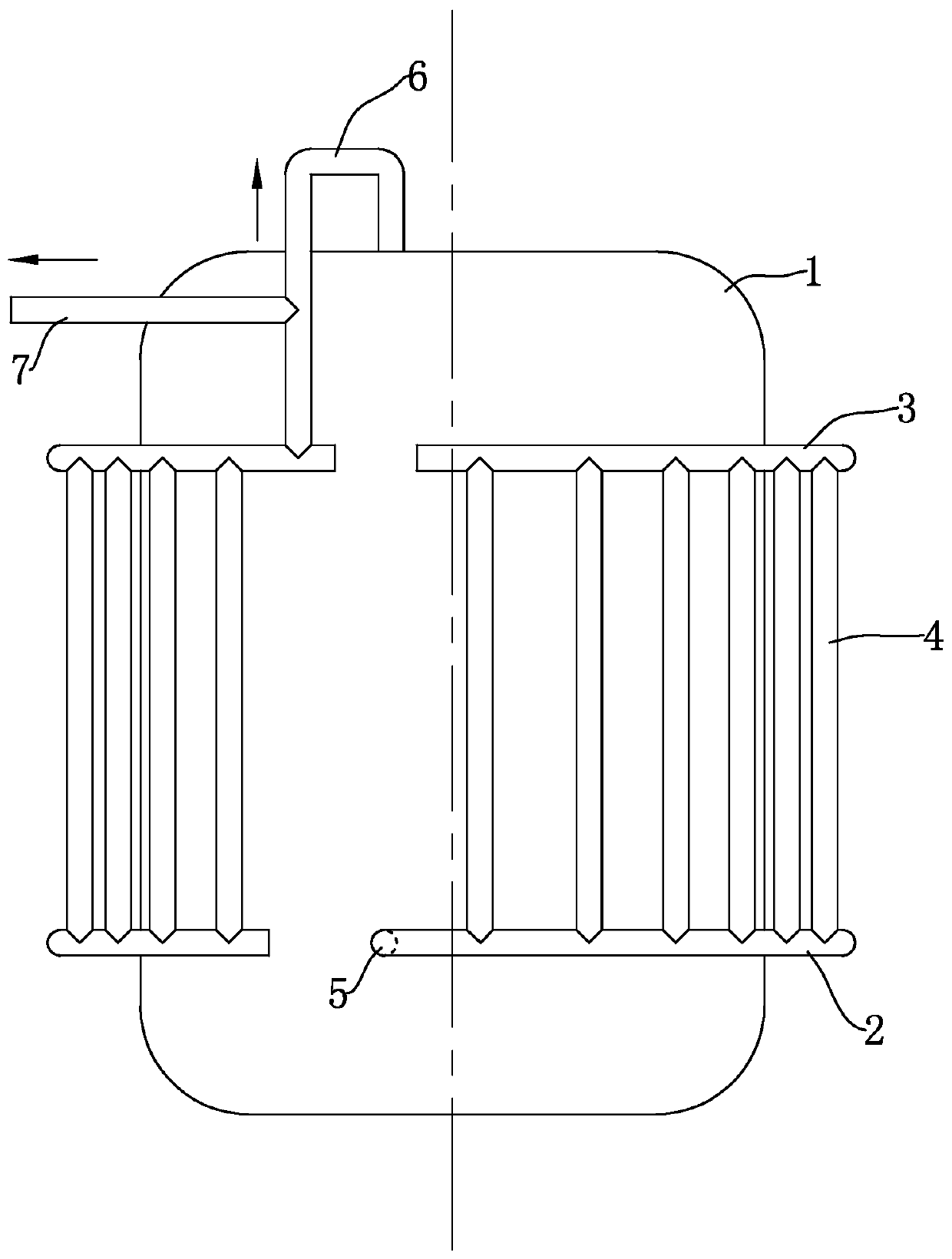

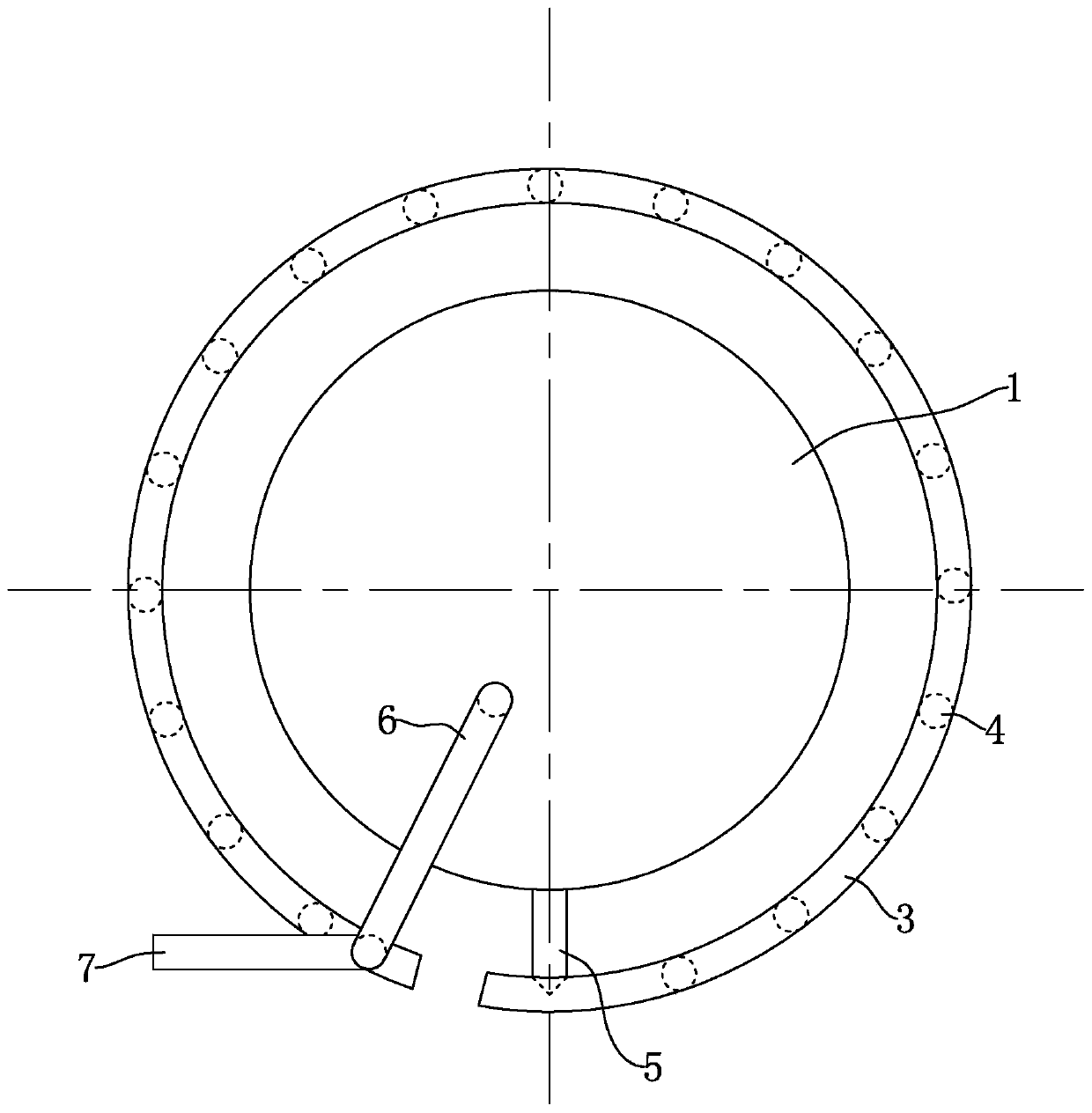

[0049] In order to facilitate the understanding of the present invention, the structure and working principle of the prior art will be briefly described first. Such as figure 1 and figure 2 As shown, the liquid natural gas storage tank 1 is surrounded by a gas outlet pipe assembly. The gas outlet pipe assembly includes a horizontally arranged gas outlet pipe 2 and an upper outlet pipe 3. Both the gas outlet pipe 2 and the upper outlet pipe 3 have disconnected gaps. The ring shape is arranged around the liquid natural gas storage tank 1; a transition pipe 4 is provided between the gas output pipe 2 and the upper output pipe 3, and the gas output pipe 2 and the upper output pipe 3 are connected through the transition pipe 4, and the transition pipe 4 are vertically arranged, and there are multiple transition pipes 4 that are evenly distributed around the circumference of the liquid natural gas storage tank 1. One end of the gas output pipe 2 is fixedly connected with a lower ...

Embodiment 2

[0063] The difference from Example 1 is that, as Figure 7 and Figure 8As shown, the heat conduction plate 23 is a hollow structure, and the inner cavity of the heat conduction plate 23 is filled with a coolant (in order to make the connection relationship between the components of the accompanying drawings clearer, the coolant is not shown in the figure), and the coolant has a relatively Liquid or gas with high thermal conductivity, if liquid is used, antifreeze coolant or cooling oil can be used, and the gas output pipeline 2 can quickly conduct heat to the position of the heat conducting plate 23 near the center of the gas output pipeline 2 through the coolant, so that the heat conduction The plate 23 quickly conducts heat to the LNG at different positions inside the gas output pipeline 2, so that the different positions of the LNG inside the gas output pipeline 2 are heated evenly, and the gasification speed of the LNG is increased.

[0064] The gas output pipe is provid...

Embodiment 3

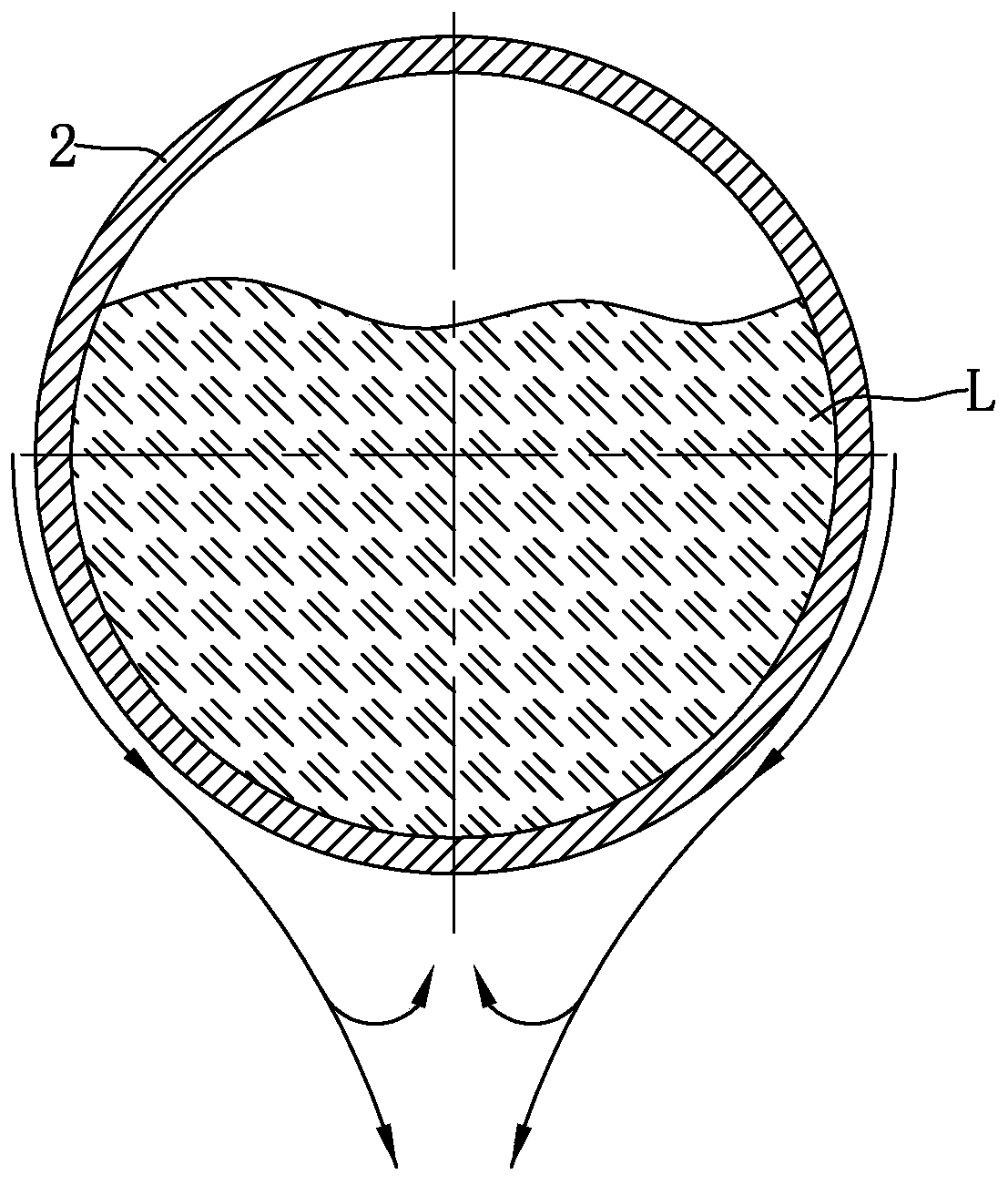

[0066] The difference from Example 2 is that, as Figure 9 As shown, due to the increase of the gasification speed of the liquid natural gas inside the gas output pipeline 2, the gas output pipeline 2 will not be filled due to the increase of the liquid natural gas, and the transition pipe 4 can be set as one; the transition pipe 4 and the gas output pipeline 2 The end away from the lower connecting pipe 5 is fixedly connected, which can increase the path length of the liquid natural gas or gas from the lower connecting pipe 5 to the transition pipe 4, and the liquid natural gas or gas can absorb more from the air during the movement in the gas output pipe 2. Lots of heat. combine Figure 10 , liquid natural gas ( Figure 10 The L refers to the liquefied natural gas) enters the gas output pipeline 2 after being gasified, and the volume of the gas increases after being heated, and the air pressure increases; the liquefied natural gas inside the liquefied natural gas storage t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com