Rapid installation type anti-freezing faucet

A quick-installation and water nozzle technology, which is applied in the direction of valve device, valve operation/release device, function valve type, etc., can solve the problems of seepage pool, short service life of water nozzle, waste of energy, poor safety and stability, etc. , to achieve the effect of filling the gap in the market, convenient water use and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

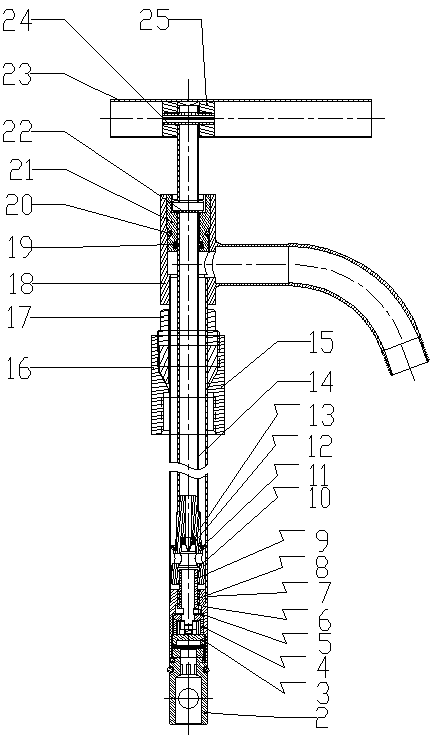

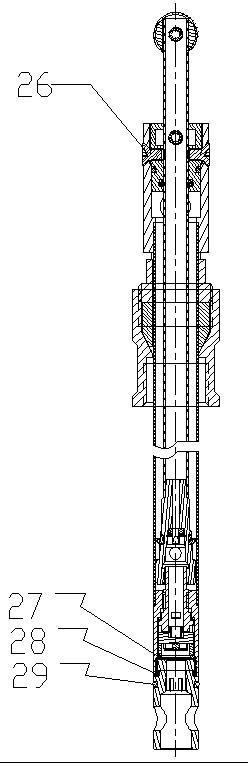

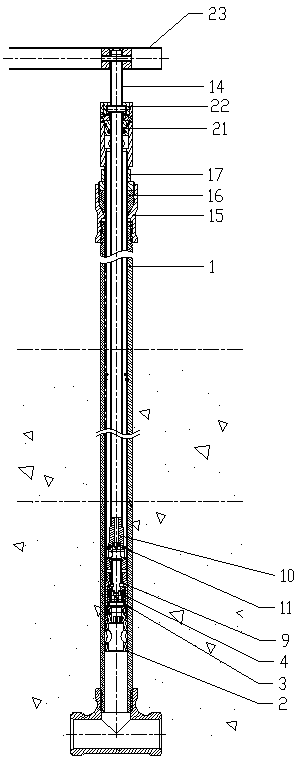

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0028] See attached Figure 1-8 , the quick-installed freeze-free faucet disclosed in the present invention includes a locking joint 2, a fixed tile 3, a moving tile 4, a wear ring 5, a fixed seat 6, a fixed pipe 7, a friction ring 8, an outer Tooth rotating rod 9, inner tooth joint 10, leather cup 11, retaining ring 12, one-way valve 13, lifting inner tube 14, fixed connection nut 15, rubber sleeve 16, lock nut 17, spout 18, V-shaped seal Rubber ring 19, O-ring 20, guide positioning joint 21, elastic pin 22, handle 23, elastic pin 24, handle joint 25, screw 26, O-ring 27, O-ring 28, O-ring 29.

[0029] The pre-embedded pipeline 1 is set at the installation position of the water pipe in advance, and the fixed pipe 7 is inserted into the pre-embedded pipeline 1 . Lock joint 1 is installed in the lower end of fixed pipe 7, and the interior of the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com