Anti-freezing fluid

A technology of antifreeze and mass percentage, applied in the field of antifreeze, can solve the problems of poor stability of antifreeze, expensive formula of organic acid type antifreeze, precipitation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

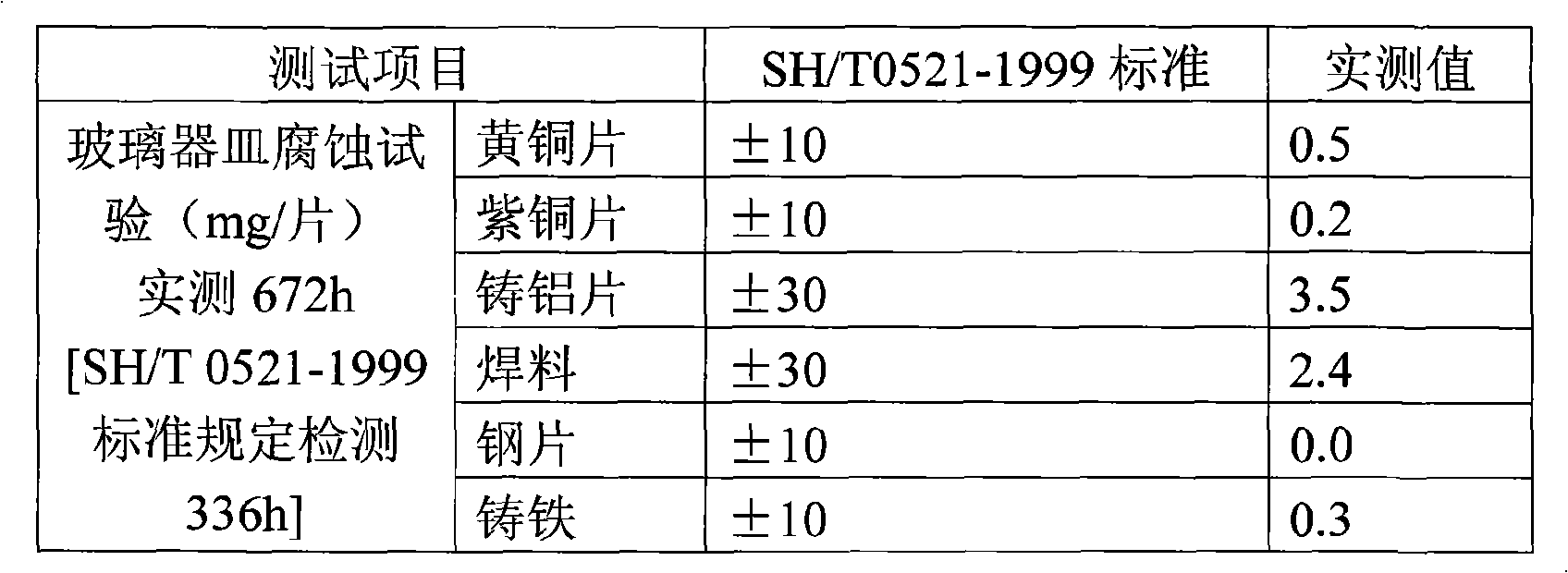

Embodiment 1

[0056] Prepare 1000kg of an antifreeze used in areas where the lowest temperature in the north is below -55°C:

[0057] Put 700kg of ethylene glycol into the reaction kettle, then add 200kg of water, start stirring, then add 0.5kg of tolyltriazole, 1.0kg of benzotriazole, 1.6kg of sodium nitrate, and 1.1kg of sodium molybdate , stir for 10 minutes to be dissolved, add 13.2kg of sodium benzoate, stir and dissolve for 15 minutes, add 13.2kg of sebacic acid, 4.4kg of undecanedibasic acid, 3.3kg of caprylic acid, and add 15kg of potassium hydroxide at the same time, dissolve and add 5.4kg of phosphoric acid with a concentration of 85%, and then adjust the pH between 7.8 and 8.5 with the remaining potassium hydroxide under stirring, then add 0.8kg of hydrolyzed polymaleic anhydride, and mix the defoamer and dye with the remaining water After adding to the reaction kettle, a light green transparent solution is finally formed. After passing the inspection, it can be filtered through ...

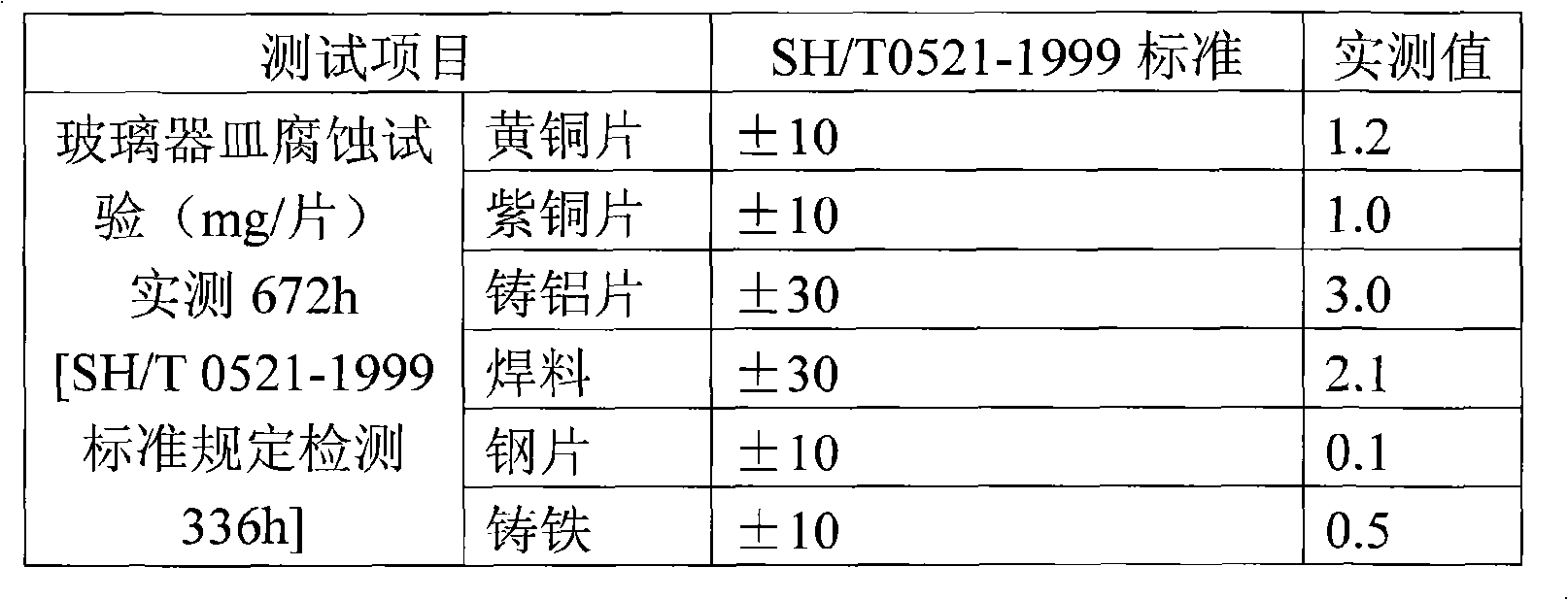

Embodiment 2

[0061] Prepare 1000kg of an antifreeze used in areas where the lowest temperature in the south is below -25°C:

[0062] Now put 400kg of ethylene glycol into the reaction kettle, then add 520kg of water, start stirring, then add 0.4kg of tolyltriazole, 0.7kg of benzotriazole, 1.2kg of sodium nitrate, and 0.8 kg of sodium molybdate kg, stirred for 10 minutes to be dissolved, then added 9.6kg of sodium benzoate, stirred and dissolved for 15 minutes, added 9.6kg of sebacic acid, 3.2kg of undecanedibasic acid, 2.4kg of caprylic acid, and 10kg of potassium hydroxide, and dissolved transparently Add 4kg of phosphoric acid with a concentration of 85%, and then adjust the pH between 7.8 and 8.5 with the remaining potassium hydroxide under stirring, then add 0.6kg of hydrolyzed polymaleic anhydride, and mix the defoamer and dye with the rest of the water The reaction kettle finally forms a light green transparent solution, which can be dispensed after being filtered through a 0.5-1μm f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com