Damping device and transporting system

A technology of vibration damping device and conveying device, applied in the direction of shock absorber, lifting device, spring/shock absorber functional characteristics, etc., can solve the problems of normal operation of mechanical equipment, labor consumption and other problems, achieve good vibration effect and save manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

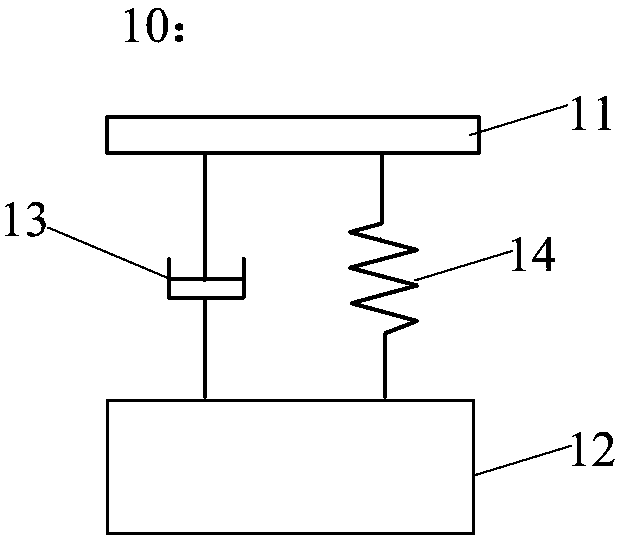

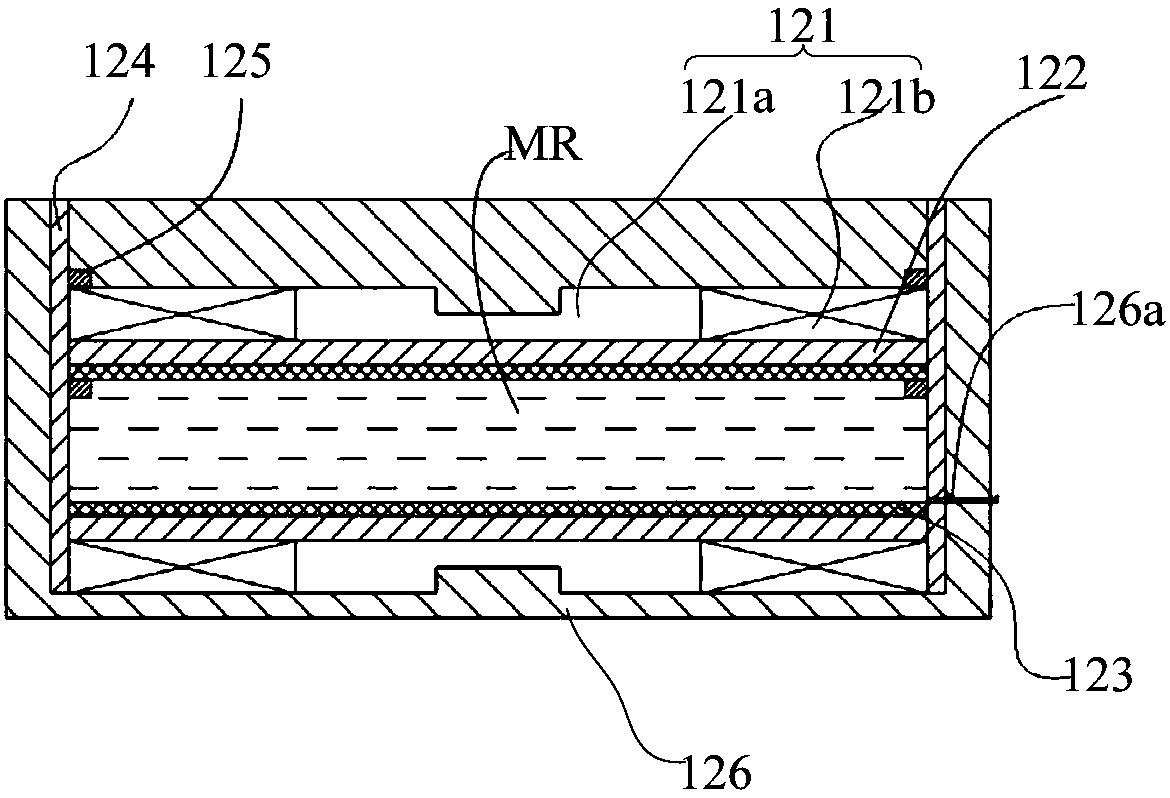

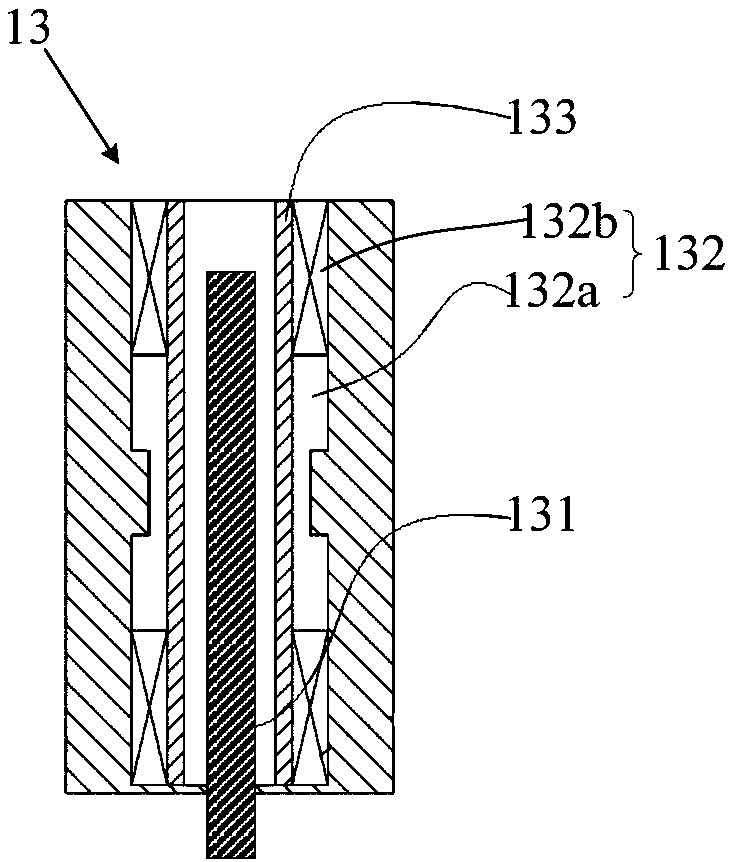

[0033] As an aspect of the present invention, a vibration damping device 10 is provided, such as figure 1 As shown, the damping device 10 includes a mounting part 11 and a mass block 12, an elastic part 14 (for example, a spring) and a damper 13 are arranged between the mass block 12 and the mounting part 11, and the two ends of the elastic part 14 are respectively connected to the installation The part 11 is connected to the mass block 12, and the two ends of the damper 13 are respectively connected to the mounting part 11 and the mass block 12. Among them, such as figure 2 As shown, the mass block 12 includes a mass block body 126 and a first accommodating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com