Workpiece sliding locking device of automatic turning lathe

A technology of sliding locking and automatic lathes, which is applied in the direction of positioning devices, auxiliary devices, tool holder accessories, etc., can solve the problems of inconsistent height, poor versatility, and inability to achieve two-way fixing at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

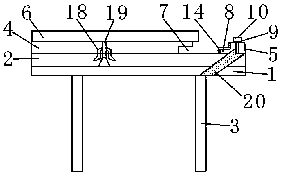

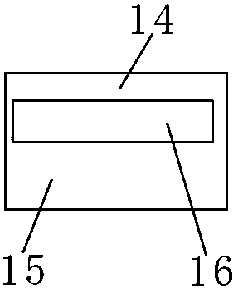

[0019] see figure 1 , the present invention provides a workpiece sliding locking device for an automatic lathe, comprising a slide rail base 1, two guide rails 2 are fixedly installed on the top of the slide rail base 1, and the two guide rails 2 are about the central axis of the slide rail base 1 Symmetrically distributed, the slide rail base 1 provides bottom support for the guide rail 2, which facilitates the installation of the guide rail 2. The two guide rails 2 are symmetrically arranged. When the object moves linearly along the guide rail 2, the guide rail 2 plays the role of supporting and guiding. Lightweight and labor-saving, the guide rail 2 has strong wear resistance, and can still maintain a certain accuracy after long-term use.

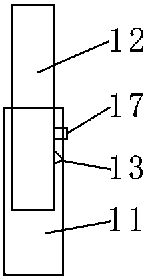

[0020] see figure 1 and figure 2 , the bottom of the slide rail base 1 is connected with several telescopic rods 3, the telescopic rods 3 are composed of a first steel pipe 11 and a second steel pipe 12, the second steel pipe 12 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com